Fiber sheet plate and usage

A thin plate and fiber technology, applied in the field of civil engineering, can solve problems such as complex equipment requirements, high material costs, and increased engineering volume, and achieve the effects of simple weaving process, good mechanical properties, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

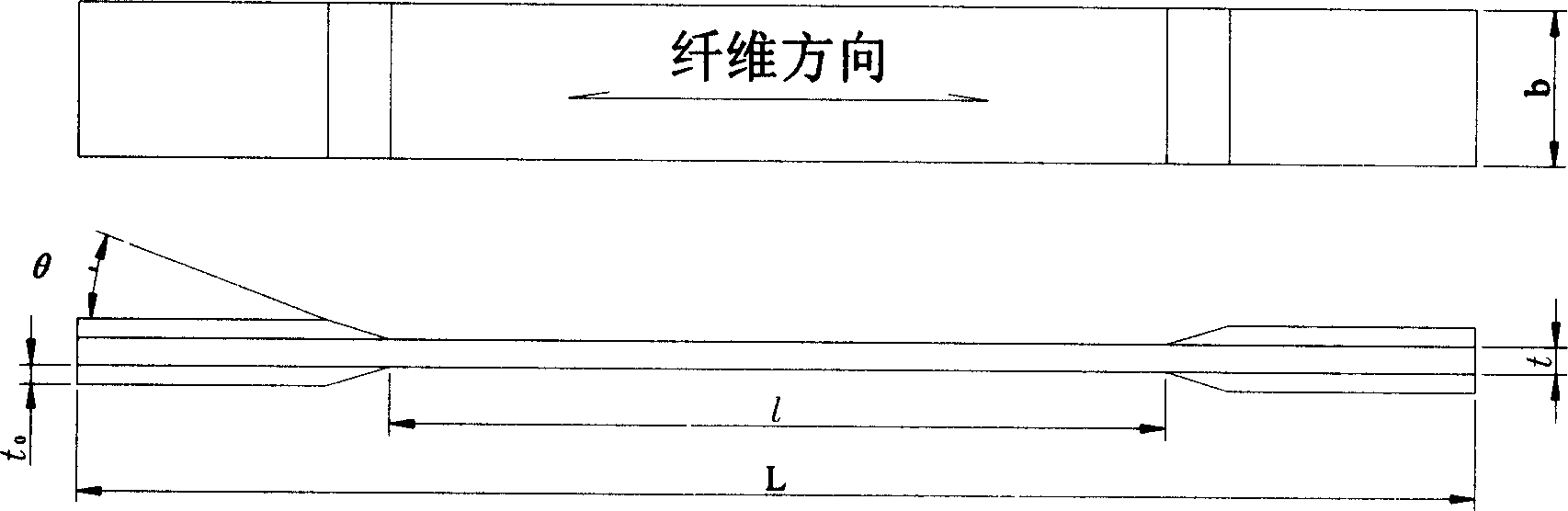

[0056] The fiber sheet is made of carbon fiber yarn HTA-3k (T300-3k), M40 and T700-12k produced by Toray Corporation of Japan, aramid fiber yarn kevlar-49 (k49) produced by DuPont Company of the United States, Nanjing Glass Fiber Design Institute The high-strength glass fiber filament SC8-12×4 produced is used as raw materials, and the impregnating material is prepared according to the ratio of "liquid epoxy resin: solid epoxy resin: polyamide = 0.8-1.3: 0.8-1.3: 0.8-1.3". A single-layer fiber sheet with a thickness of 0.45 mm to 0.65 mm (calculated thickness of 0.153 mm to 0.391 mm), a width of 50 mm to 150 mm, and a length of <100 meters was prepared on the braiding machine. The specifications and material components are shown in Table 2. shown.

[0057] fiber raw material

density

(g / cm 3 )

Fiber sheet model

Fiber Sheet Specifications

(width×thickness, mm)

Calculate thickness

(mm)

Dip material

(Proportion)

C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com