Patents

Literature

40results about How to "Lower spinning temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of preparing PDT copolyester fiber

InactiveCN101046007ASpinning high speedHigh speed spinning equipmentMonocomponent copolyesters artificial filamentFiberAlcohol

The process of preparing PDT copolyester fiber includes the following steps: 1. saccharifying and catalytically hydrogenating corn starch to prepare sorbitol, catalytically hydrogenating to prepare multicomponent mixed alcohol, and fractionating in a fractionating tower at 182-212 deg.c to obtain corn-base ethylene glycol product of 89-99 % content and with ethylene glycol as main component and other diols; 2. detecting the contents of component diols in the ethylene glycol product and adding insufficient components for content fluctuation controlled within 10-30 %; and 3. adding nanometer titania in 0.05-1 wt% into the corn-base ethylene glycol product, and copolymerizing together with terephthalic acid at 280-288 deg.c for 5-7 hr to prepare PDT copolyester. The process is suitable for industrial production.

Owner:DONGHUA UNIV

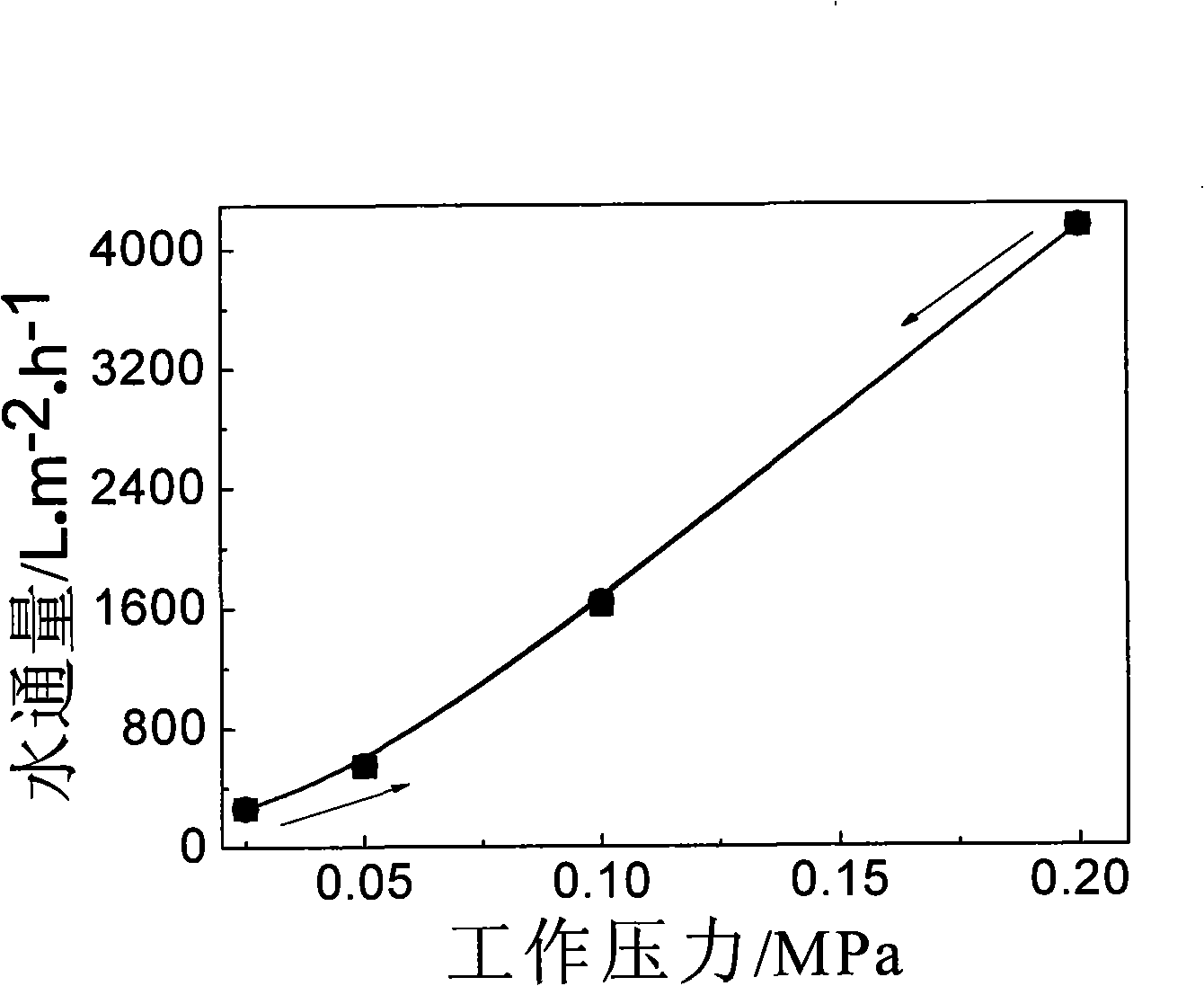

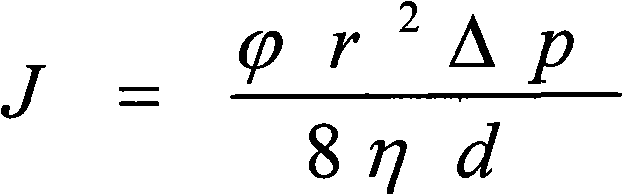

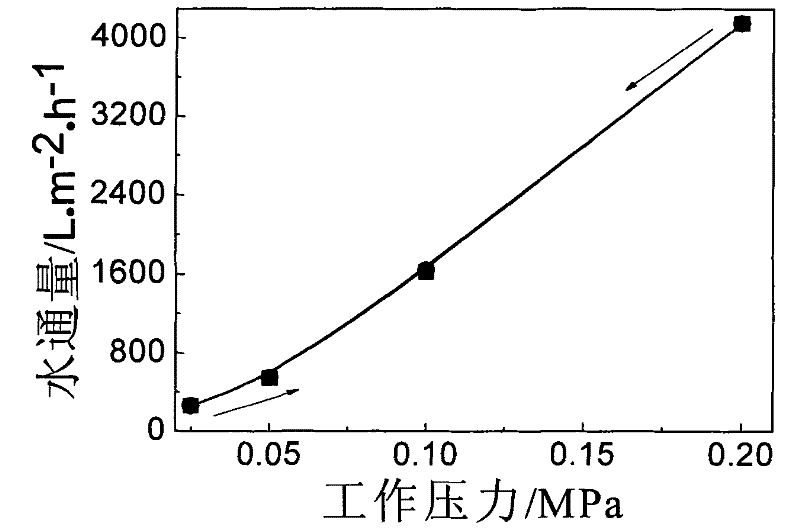

Hollow fiber film and method for producing the same

InactiveCN101322922AIncrease elasticityIncrease water fluxMembranesSemi-permeable membranesPolymer scienceSolvent

The invention relates to a hollow fiber membrane and a manufacturing method thereof. The weight percentage prescription of the membrane forming system of the membrane is: 25 to 45 percent of polyurethane; 35 to 60 percent of compound pore-forming agent; 15 to 20 percent of organic low molecular; the sum of each component is 100 percent; wherein, the polyurethane is a fiber grade; the weight ratio of a hard section and a soft section is 1 / 1 to 1 / 5; the compound pore-forming agent is the mixture of an interface cavity pore-forming agent and a non-interface cavity pore-forming agent; the organic low molecular liquid is a good water-soluble polyurethane solvent with a high boiling point; the manufacturing method of the membrane adopts the following melt spinning technique: firstly the prescription of the invention demands the preparation of a polymer membrane forming system; then the polymer membrane forming system is poured into a mixing tank to carry out heating, reinforcing and pre-mixing with a heating temperature of 130 to 140 DEG C; the polymer membrane forming system is injected into a double screw extruder after being uniformly mixed; melt blending spinning is carried out to manufacture the membrane under the temperature of 130 to 155 DEG C; then the hollow fiber membrane is obtained after the normal working procedure of water extraction washing.

Owner:TIANJIN POLYTECHNIC UNIV

Modified polyphenylene sulfide fiber and method for making same

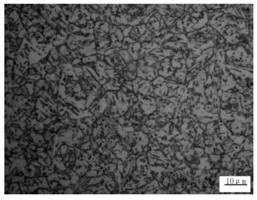

InactiveCN101187088AHigh glossImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentMelt spinning methodsUltimate tensile strengthSilicon dioxide

The invention provides a modified polyphenylene sulfide fiber and process for preparing, whose components and parts by weight comprise 100 parts of polyphenylene sulfide and 0.2-2 parts of nano-silica whose surface is treated, the particle size of the silica is 20-60 nanometer, and the denier of the fiber is 85-91 dtax. The invention prepares the polyphenylene sulfide fiber through modifying polyphenylene sulfide resins and using special spinning process, the fiber strength and tension toughness are all improved, simultaneously, the glossiness of the fiber is further improved, the spinning is capable of being done by a common spinning device, the cost of spinning is reduced, the fluidity of substrate is changed better during spinning, the temperature of spinning is reduced by 5-10 DGE C, the draft multiple of as-spun fiber is improved, and the mechanical properties of the fiber are capable of being improved.

Owner:DONGHUA UNIV

Low temperature producing method for nylon fiber

InactiveCN101054740AImprove securityLower spinning temperatureMelt spinning methodsArtifical filament manufactureAntistatic agentUv absorber

The present invention discloses a technology field relating to the preparation method of textile materials, especially to a process for for low temperature production of nylon fibre. Said process comprises the steps of adding a mixture of metallic compounds during or before nylon melting course and then spinning the obtained molten mass at a low temperature of 160-250 DEG C. Adding auxiliaries of oxidation preventives, ultraviolet absorbents, light-stability agents and anstatic agents therein before the melting course or during the melting course will result in more excellent effects. The method has a lower energy consumption and a lower cost, and its industry operations are more convenient and safe, will find wide use in industries such as garments and intertexture.

Owner:HANGZHOU NORMAL UNIVERSITY +1

Hollow fiber porous film and process for producing same

Owner:TIANJIN POLYTECHNIC UNIV

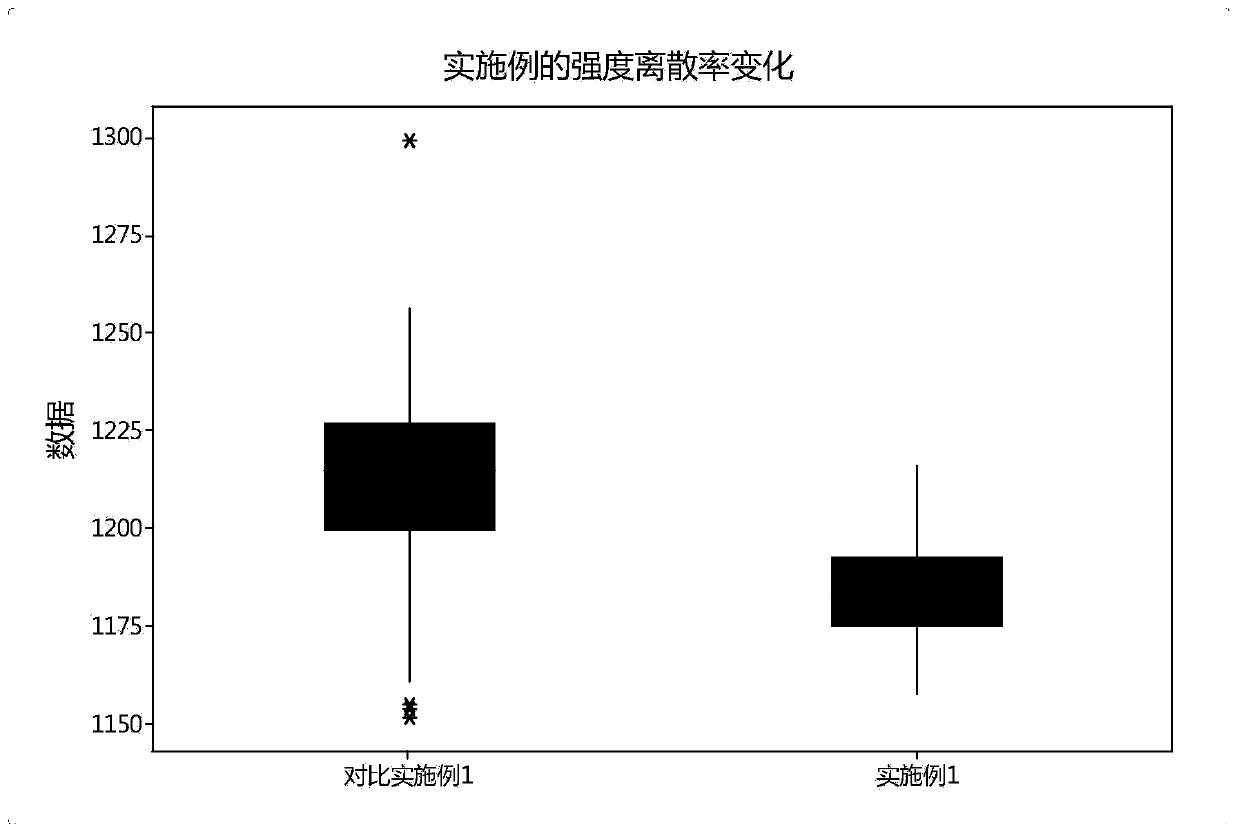

Steel wire rod with 600MPa-grade yield strength and used for welding wire, and production method thereof

The invention discloses a steel wire rod with 600MPa-grade yield strength and used for a welding wire, and a production method thereof. The steel wire rod with the 600MPa-grade yield strength and usedfor the welding wire comprises the following chemical components in percentage by mass: 0.06%-0.12% of C, 0.35%-0.45% of Si, 1.55%-1.70% of Mn, not greater than 0.020% of P, not greater than 0.010% of S, 0.25%-0.40% of Cr, 1.70%-1.95% of Ni, 0.42%-0.52% of Mo, 0.10%-0.12% of Ti, and the balance Fe and inevitable impurities. The mechanical property of the provided steel wire rod for the welding wire meet the following conditions: the yield strength is not less than 600MPa, the elongation is not less than 25%, the percentage reduction of area is not less than 70%, and the steel wire rod for thewelding wire can be applied to the high-strength steel welding fields of coal mine machinery, containers, buildings, ships, bridges and the like.

Owner:BAOTOU IRON & STEEL GRP

Steel wire rod for bainite high-strength welding wire and production method thereof

The invention discloses a steel wire rod for a bainite high-strength welding wire and a production method thereof. The steel wire rod for the bainite high-strength welding wire comprises the followingchemical components of, in percentage by mass, 0.05%-0.11% of C, 0.35%-0.65% of Si, 1.60%-1.80% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.25%-0.37% of Cr, 1.45%-1.85% of Ni, 0.42%-0.52% of Mo, 0.13%-0.16% of Ti, and the balance Fe and unavoidable impurities. The mechanical property of the steel wire rod for welding wire meets the conditions that the tensile strength is larger than or equal to 900 MPa, the elongation is larger than or equal to 25%, the cross-section shrinkage rate is larger than or equal to 70%, and the steel wire rod can be applied to thefield of high-strength steel welding of coal mine machinery, containers, buildings, ships, bridges and the like.

Owner:BAOTOU IRON & STEEL GRP

Aromatic, hydrophilic and antistatic composite functional polyester fibers as well as preparation method and application

InactiveCN105803574AImprove hydrophilic abilityWith antistatic functionElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterPolymer science

The invention discloses a preparation method of aromatic, hydrophilic and antistatic composite functional polyester fibers. High-temperature-resisting powdery essence is selected and uniformly mixed with low-smelting-point polyester powder, an antistatic agent, a dispersant, a coupling agent and an anti-oxidant, and then the mixture is extruded and granulated to prepare aromatic polyester master batches. Double-screw-rod composite spinning equipment is adopted, a mixture of the aromatic polyester master batches and low-smelting-point polyester slices is used as a core and a constant-pressure cation dyeable polyester chip is used as a skin to prepare the aromatic, hydrophilic and antistatic composite functional polyester fibers. The composite functional polyester fibers prepared by the invention can release aromatic flavor for a long period and have washing endurance; the hydrophilic property is strong and the moisture regain reaches more than 0.8 percent; the aromatic, hydrophilic and antistatic composite functional polyester fibers have an antistatic function and the specific resistance is M*10<7>omega.CM (M is more than or equal to 1.0 and less than 10); the aromatic, hydrophilic and antistatic composite functional polyester fibers are easily colored and strong in color fastness.

Owner:HIGHTEX CO LTD ZHEJIANG

Preparation method of environment-friendly high-strength high-modulus polyethylene fibers

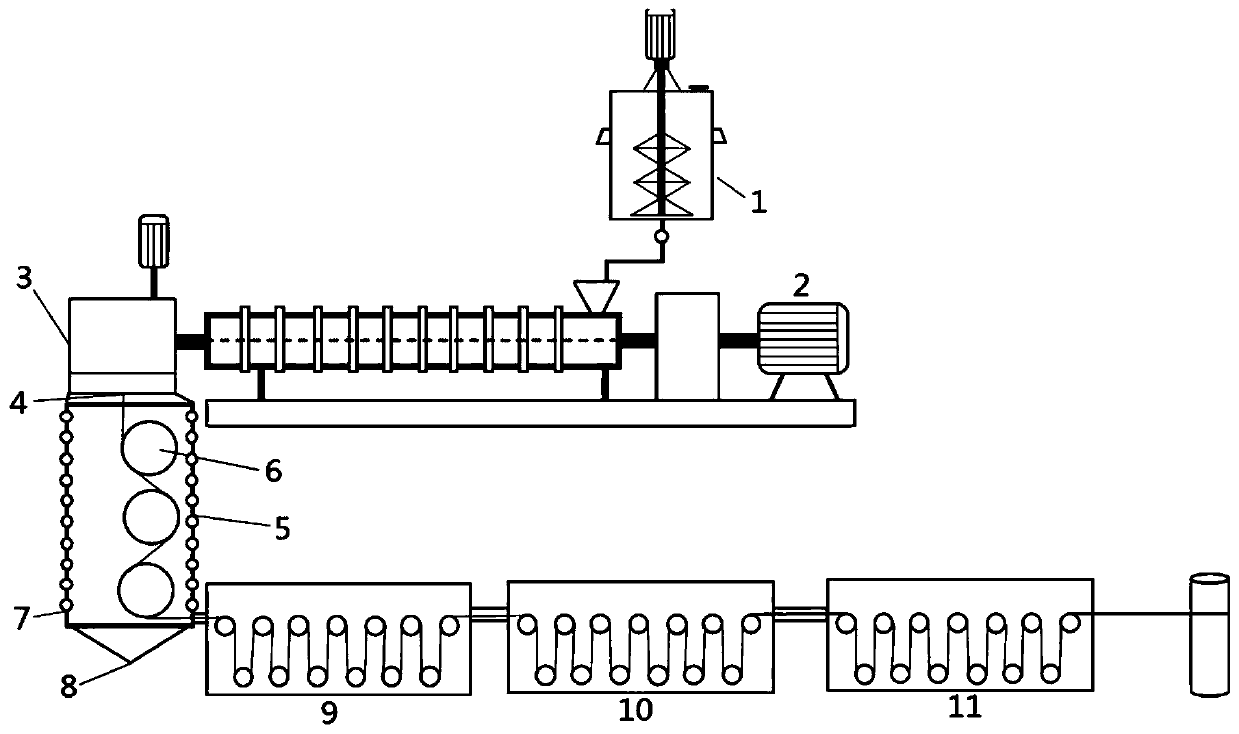

ActiveCN110079881ABig pollutionSmall mechanical propertiesArtificial filament heat treatmentMonocomponent polyolefin artificial filamentPolymer scienceSolvent

The invention relates to a preparation method of environment-friendly high-strength high-modulus polyethylene fibers. The preparation method comprises the following steps: mixing ultrahigh molecular weight polyethylene and decahydronaphthalene at a certain ratio to prepare spinning solution, enabling the spinning solution to enter a twin-screw extruder and a spinning box after swelling, entering acalorstat after extruding by a spinneret plate, entering a multistage hot roller drying device after shaping by cooling of a cold roller in the calorstat and finally dragging a hot roller for ultra-drawing and rolling up for shaping. The strength of the prepared fibers can reach above 40 cN / dtex, and the modulus is above 1,800 cN / dtex; compared with the traditional spinning method, the preparation method has the characteristics of being short in process, low in energy consumption, environmentally friendly, free of secondary solvent introduced into aftertreatment, uniform in fiber number and so on; the prepared fibers can be used for preparing body armors, bullet proof helmets, protective armors, high-strength marine cables, anti-cutting gloves, summer sleeping mats, arm guards and the like.

Owner:SHANGHAI RES INST OF CHEM IND

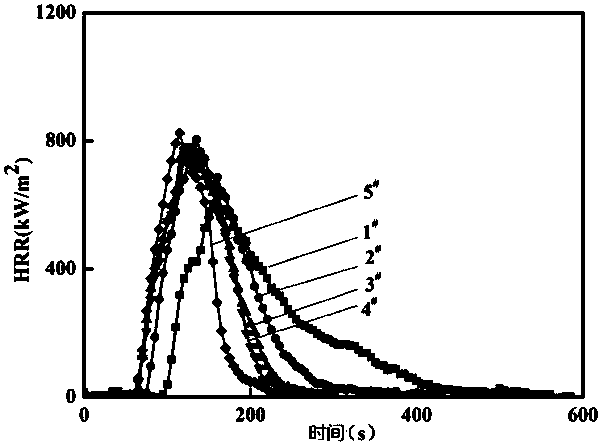

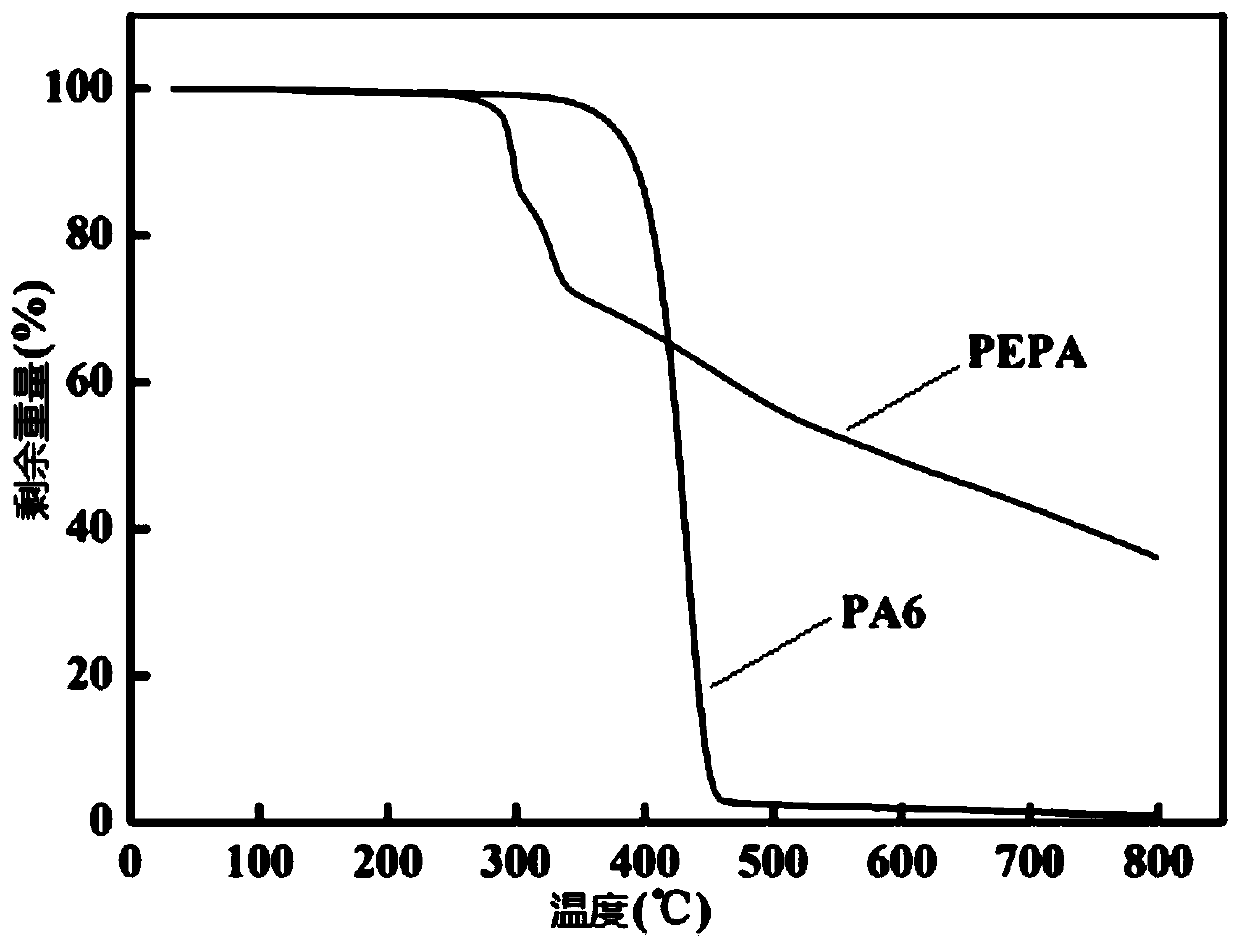

Flame retardant nylon composition

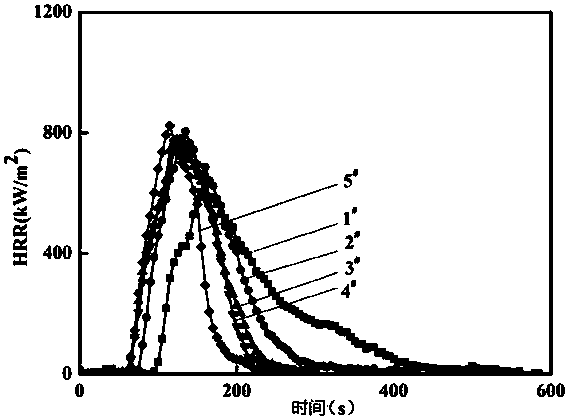

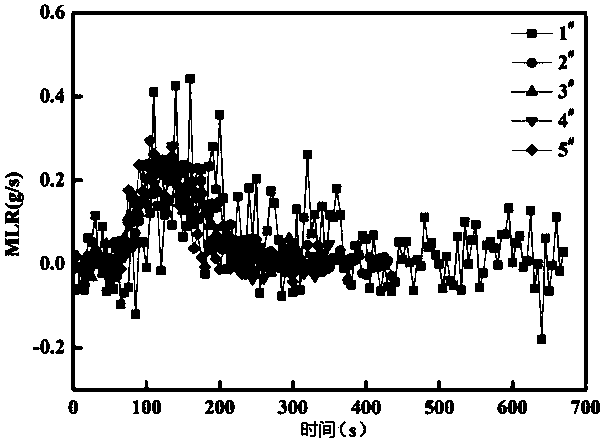

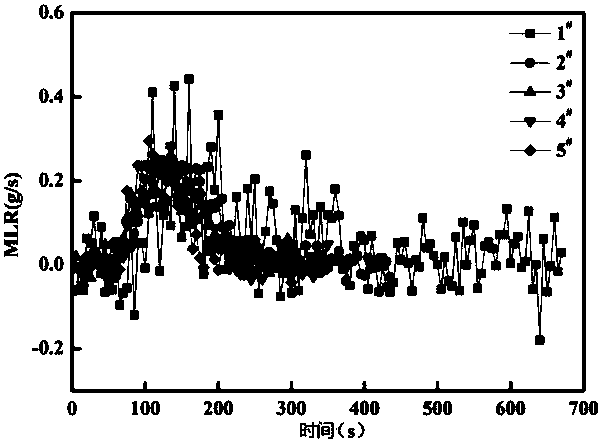

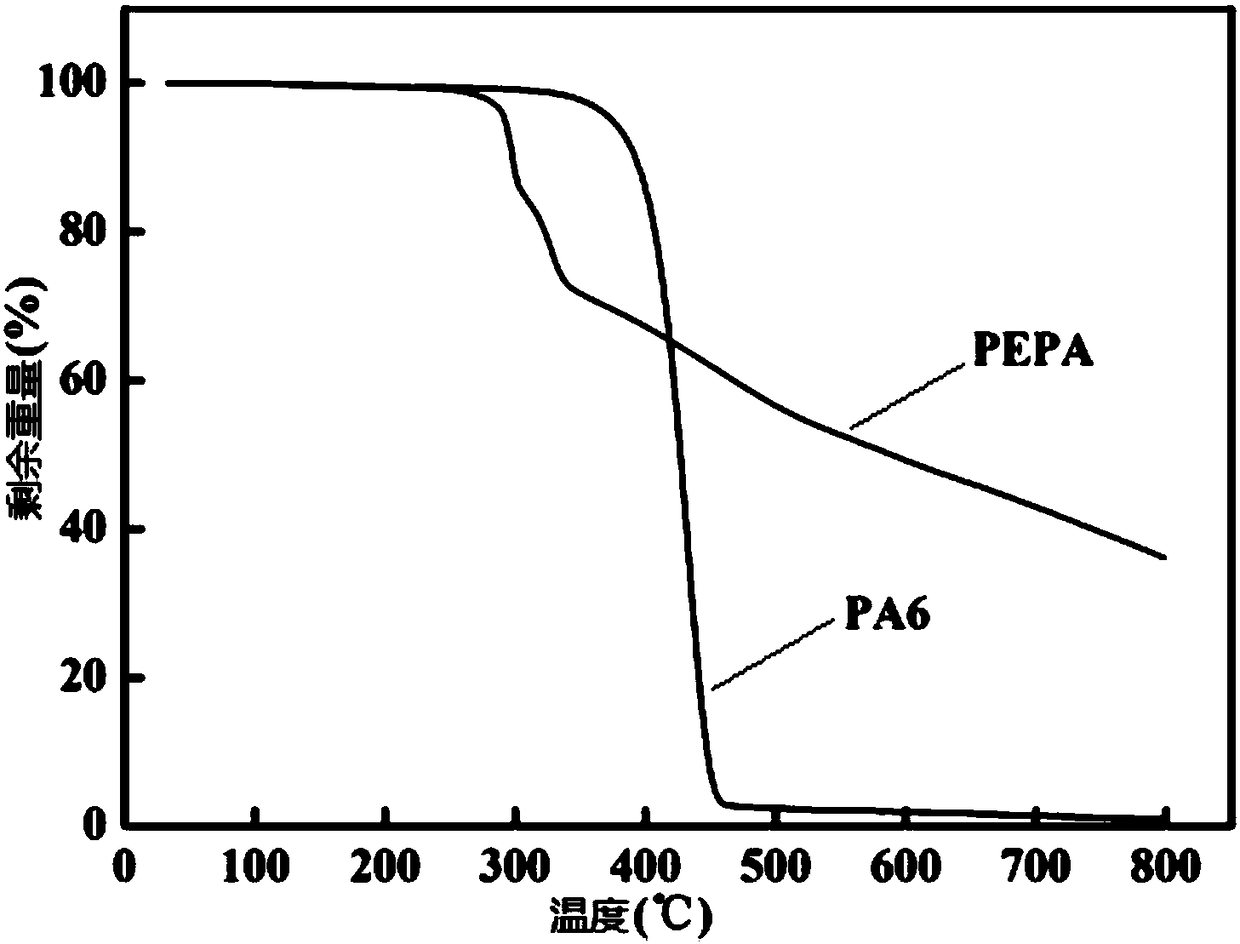

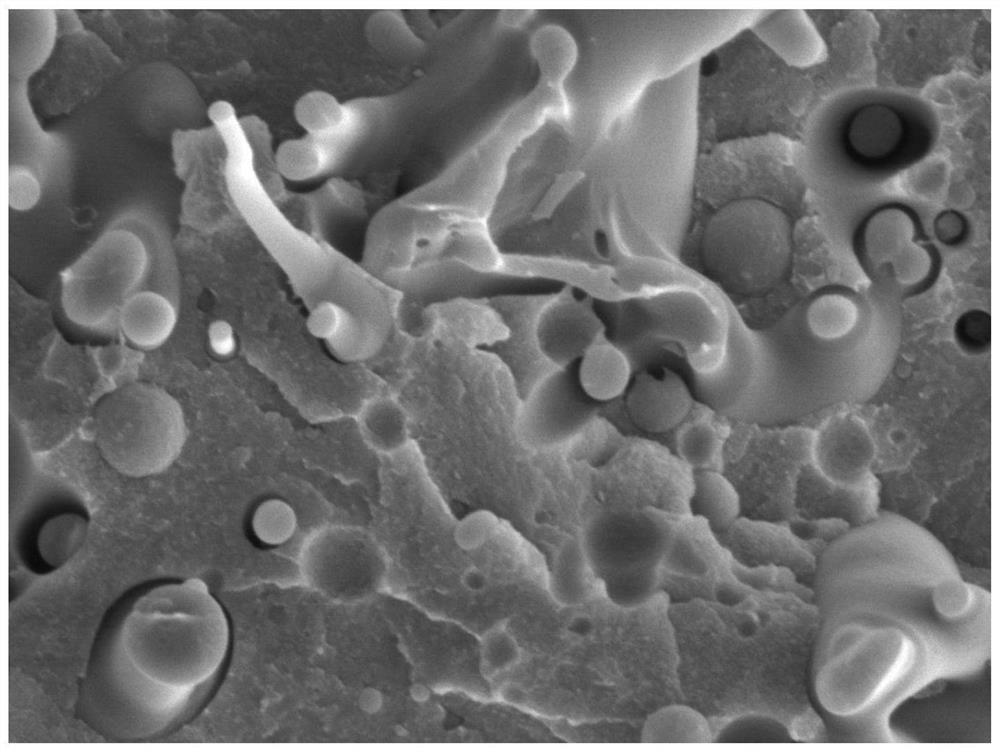

ActiveCN108059826AImprove rheologyImprove liquidityFlame-proof filament manufactureMelt spinning methodsPentaerythritolPolymer chemistry

The invention provides a flame retardant nylon composition, wherein the flame retardant nylon composition includes PA6 and pentaerythritol phosphonate. The nylon composition has the advantages of goodspinnability, flame retardancy, fluidity and rheology, and can reduce the spinning temperature and increase the spinning speed.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Imitated nylon modified fibre of dyeable polypropylene

InactiveCN101333691AImprove liquidityImprove flexibilityMonocomponent polyolefin artificial filamentArtifical filament manufactureEthyleneDyeing

The invention relates to an imitated nylon differential fiber of dyeable polypropylene fiber for dyeing, which comprises: 80 to 90 percent of polypropylene, 9 to 11 percent of dyeable master batch, 0.3 to 0.7 percent of cooling auxiliary agent and 4.0 to 5.0 percent of polyethylene. The fiber has the advantages that: firstly, the polypropylene fiber has the flexibility, tensile property and elasticity as nylon through modifying the polypropylene fiber; and secondly, the dyeability of the modified polypropylene fiber is realized.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

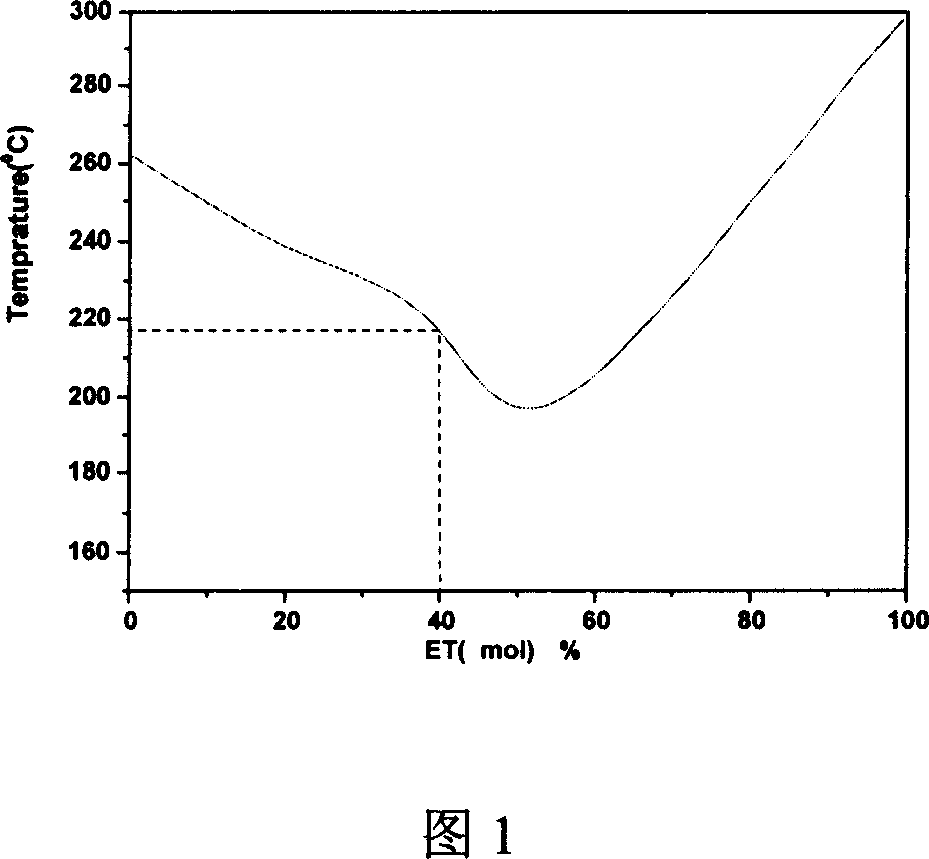

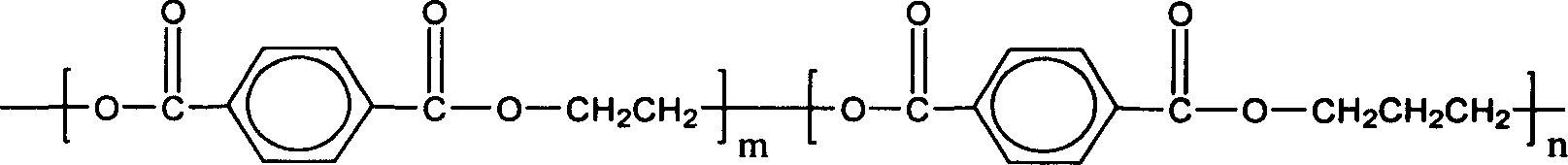

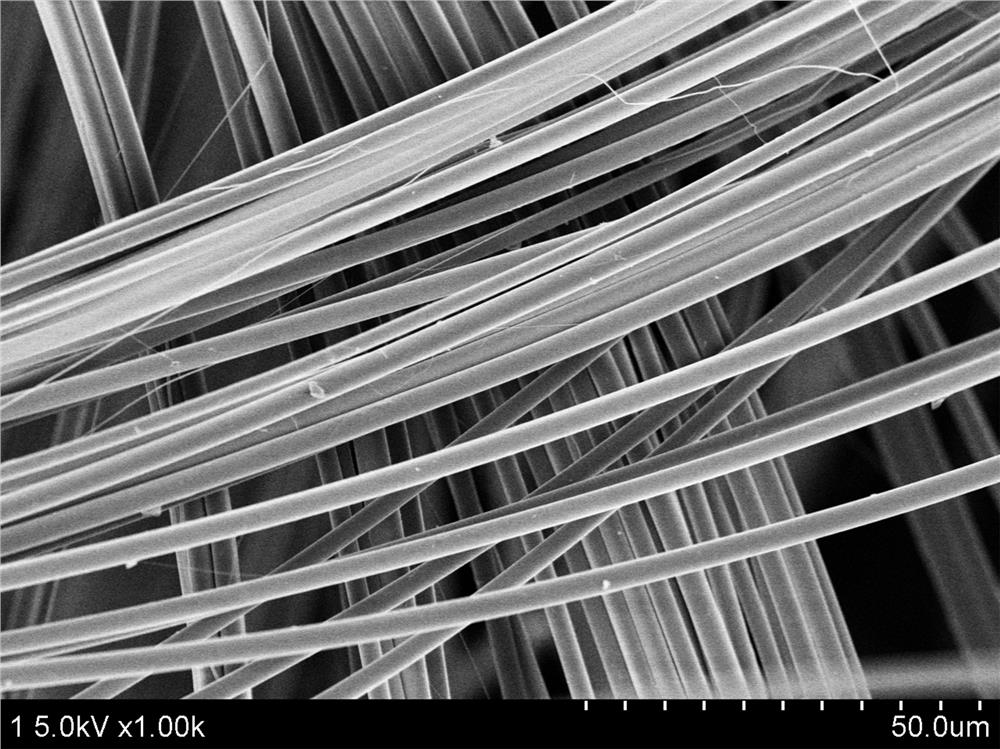

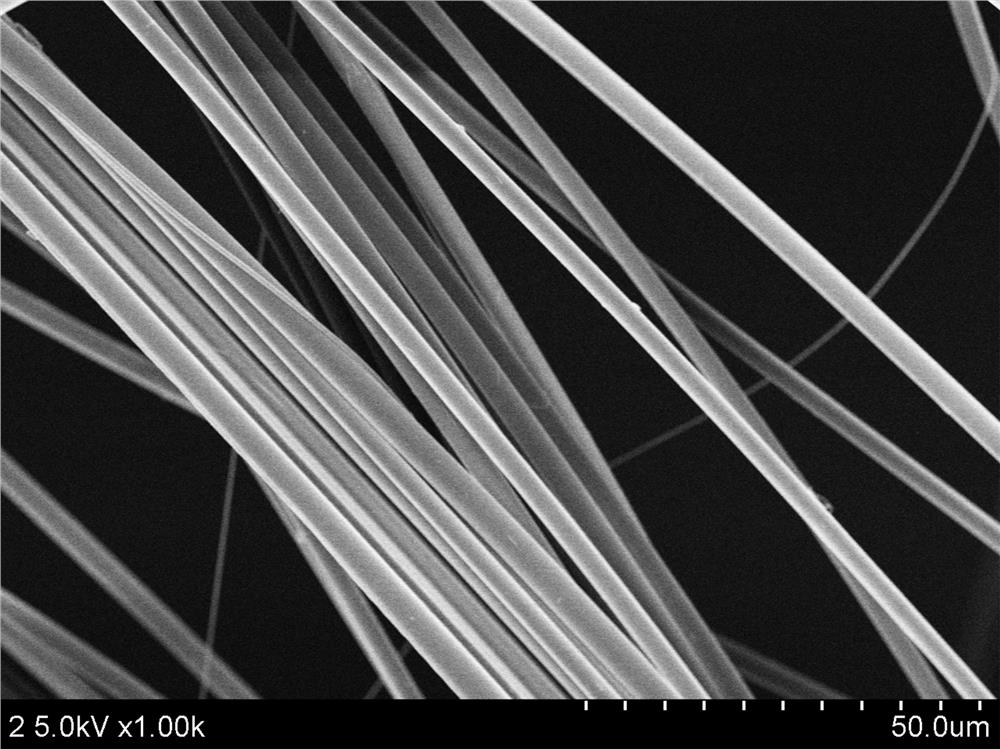

PET/PTT copolyester fiber and its production process

InactiveCN1932093AReduce manufacturing costEasy to processMonocomponent copolyesters artificial filamentMelt spinning methodsFiberChain structure

The present invention discloses one kind of PET / PTT copolyester fiber and its production process. The PET / PTT copolyester fiber has chain structure with ET units accounting for 0.05-0.95 of the total chain units and limiting viscosity value of 0.6-0.9 dL / g. The PET / PTT copolyester fiber is superior to Dacron in softness, dyeability, elasticity, etc. and has high strength similar to that of Dacron. The production process optimizes the performance of the fiber and lowers the production cost.

Owner:DONGHUA UNIV

Process for producing nylon fibre under low temperature

InactiveCN100580159CLower spinning temperatureReduce energy consumptionMelt spinning methodsArtifical filament manufactureMischmetalPolymer science

The invention discloses a method for producing nylon fiber under low temperature, which includes adding a rare-earth metal compound before or when the nylon is in melted state and conducting the spinning of the molten mass under low temperature between 160 DEG C and 250 DEG C. The energy consumption and cost of the method are low with more convenient and safer industrial operations.

Owner:PEKING UNIV +1

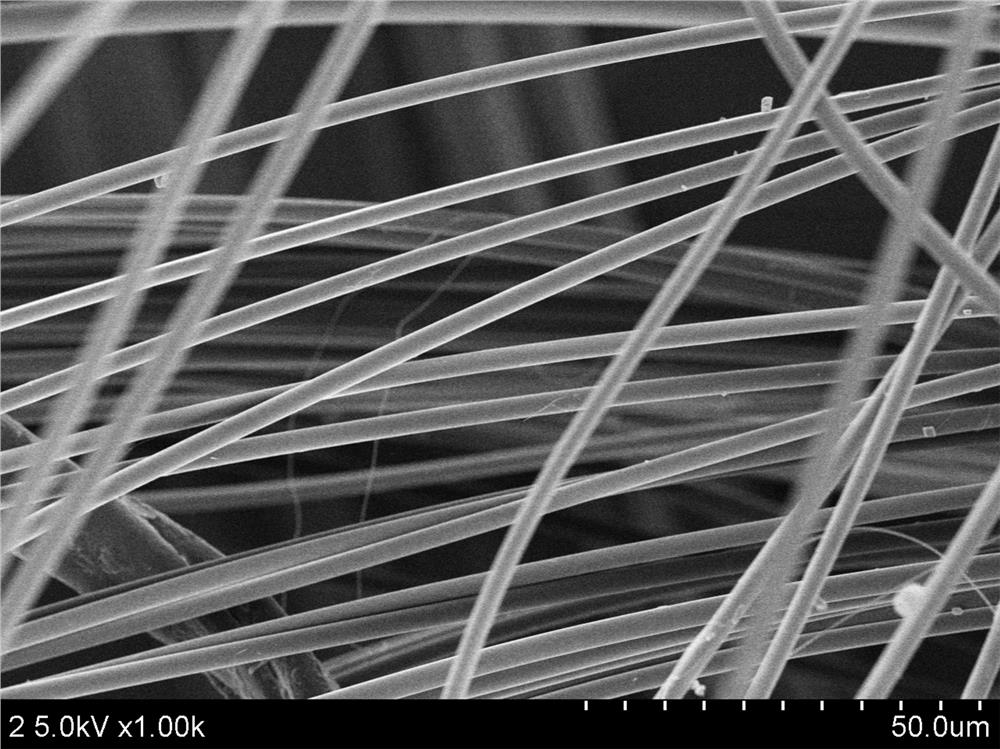

Sea-island polyphenylene sulfide superfine fiber and preparation method thereof

ActiveCN113151930AImprove liquidityNo pollution in the processTextile/flexible product manufactureConjugated synthetic polymer artificial filamentsPolyesterOrganosolv

The invention belongs to the technical field of fiber manufacturing, and discloses sea-island polyphenylene sulfide superfine fiber and a preparation method thereof. The method comprises the steps of performing melt blending granulation on polyphenylene sulfide A, polyphenylene sulfide B and polyphenylene sulfide C to obtain polyphenylene sulfide particles; mixing the polyphenylene sulfide particles with alkali-soluble polyester, carrying out melt spinning, carrying out heat setting, and performing drafting to obtain composite sea-island fiber of polyphenylene sulfide and polyester; and adding a sodium hydroxide solution into the composite sea-island fiber, and dissolving the alkali-soluble polyester to obtain the sea-island polyphenylene sulfide superfine fiber. The method is simple to operate, the spinnability and safety are improved, no organic solvent pollution is caused, and the prepared sea-island type polyphenylene sulfide superfine fiber has excellent properties such as good hand feeling, heat stability, chemical corrosion resistance and high strength. The preparation method disclosed by the invention is suitable for preparing the sea-island type polyphenylene sulfide superfine fiber, and the prepared sea-island type polyphenylene sulfide superfine fiber is suitable for preparing a battery diaphragm.

Owner:DONGHUA UNIV

Medical fiber and manufacturing method thereof

InactiveCN101476172ALess waterAvoid yellowingMonocomponent protein artificial filamentFilament/thread formingFiberCobalt-60

The invention relates to a medical fibre and a manufacturing method thereof. The medical fibre has characteristics in composition by weight percent: 59.99-89.9% glutin with average molecular weight 10-20 ten thousands; 1-5% sericin with average molecular weight 1000-40000; 9-35% fibroin with average molecular weight 80-4000; 0.01-0.1% cross linker that is 1-ethide-3, 3-dimethyl aminopropyl-carbodiimide and / or N-hydroxide radical succimide. The method includes steps as follows: placing glutin, sericin and fibroin into distilled water according with weight percent composition, swelling 150-200 miniutes under 70-95 DEG. C for preparing spinning stock solution, reducing temperature to 35-45 DEG. C after filtering and deaeration, adding cross linker and mixing; using centrifugal spinning technique for spinning, drying and forming the obtained fibre rapidly, then placing into a vacuum baking oven for baking further, collecting, packaging, irradiating sterilizing by cobalt 60 gamma, and obtaining the medical fibre.

Owner:TIANJIN POLYTECHNIC UNIV

Low temperature producing method for nylon fiber

InactiveCN101054736AImprove securityLower spinning temperatureMelt spinning methodsArtifical filament manufactureAntistatic agentChemical compound

The present invention discloses a method for preparation and production of textile material, especially to a process for low temperature production of nylon fibre. The present invention adopts a melt spinning process and comprises the steps of adding chemical compounds of the first main group metals during the nylon melt spinning course and then spinning the obtained molten mass at a low temperature of 160-250 DEG C. Adding auxiliaries of oxidation preventives, ultraviolet absorbents, light-stability agents and anstatic agents therein before the melting course or during the melting course will result in more excellent effects. The nylon fibre loomage prepared in accordance with the present invention is characterized by its absorbing sweat, lightweight, excellent toughness, rebound resilience and anti-acid alkali and the like, find wide use in industries such as garments and intertexture.

Owner:HANGZHOU NORMAL UNIVERSITY +1

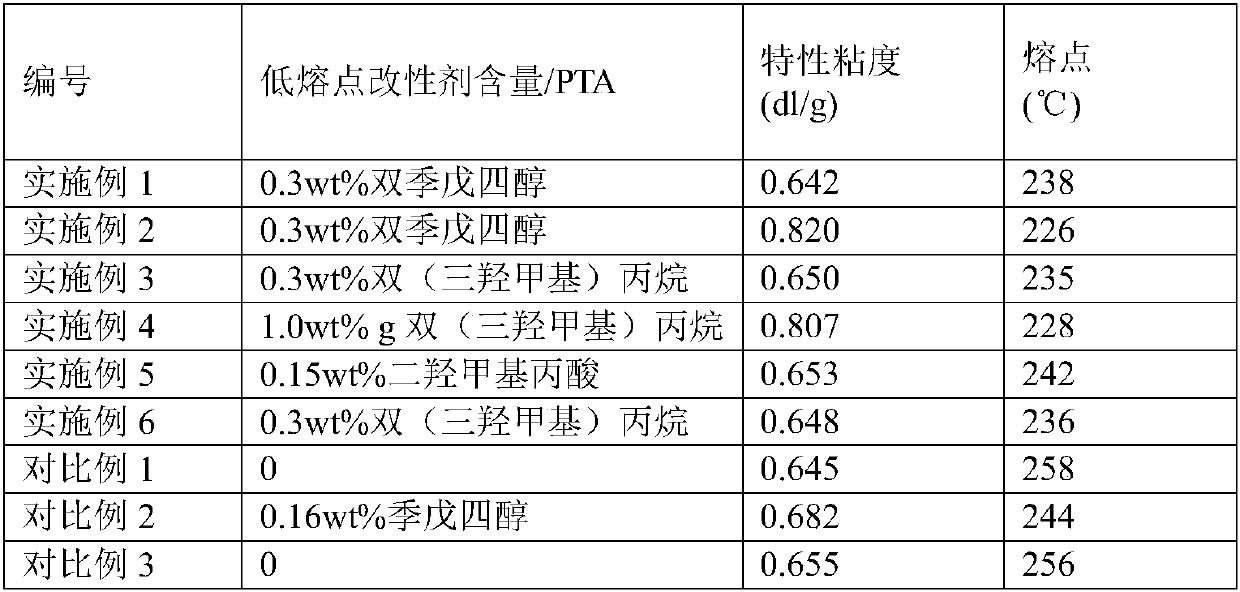

Low-melting-point polyester and preparation method thereof

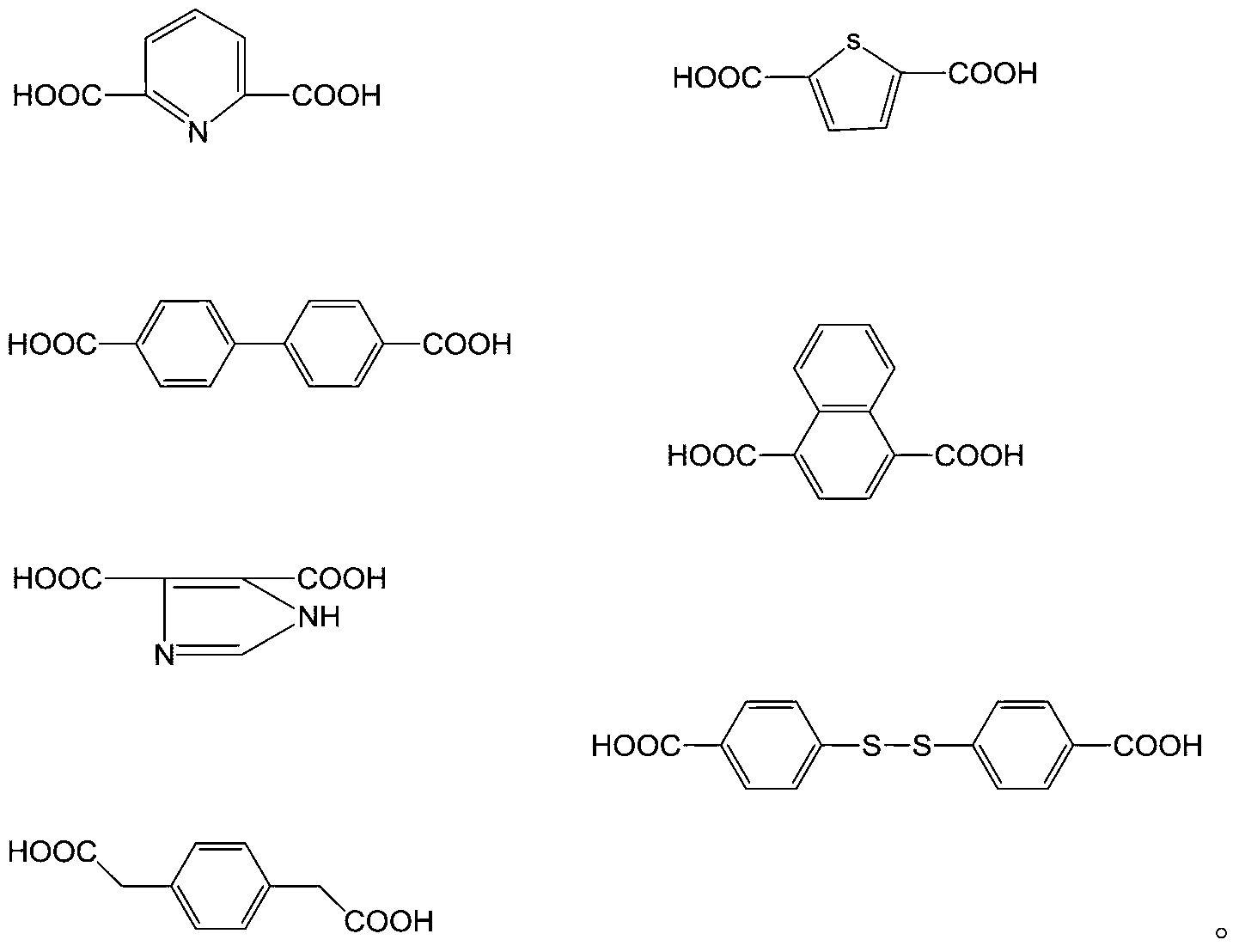

ActiveCN111072938ALow melting pointReduce contentTextile/flexible product manufactureMonocomponent copolyesters artificial filamentPolymer sciencePtru catalyst

The invention relates to the field of polyester materials, and discloses a low-melting-point polyester and a preparation method thereof. The low-melting-point polyester comprises the following raw materials by weight: 100 parts of terephthalic acid, 40-65 parts of ethylene glycol, 0.01-1 part of a low-melting-point modifier, and 0.02-0.12 part of a catalyst. The melting point of the polyester canbe effectively reduced only by adding an extremely small amount of modifier, the thermal stability and the spinnability of the polyester are not influenced, the synthesized polyester can be used for fiber spinning, and the obtained fiber has higher elongation at break and better dyeing property than the conventional fiber.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

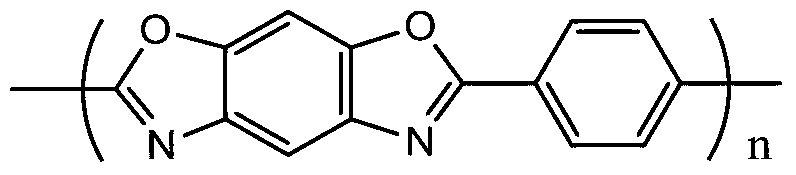

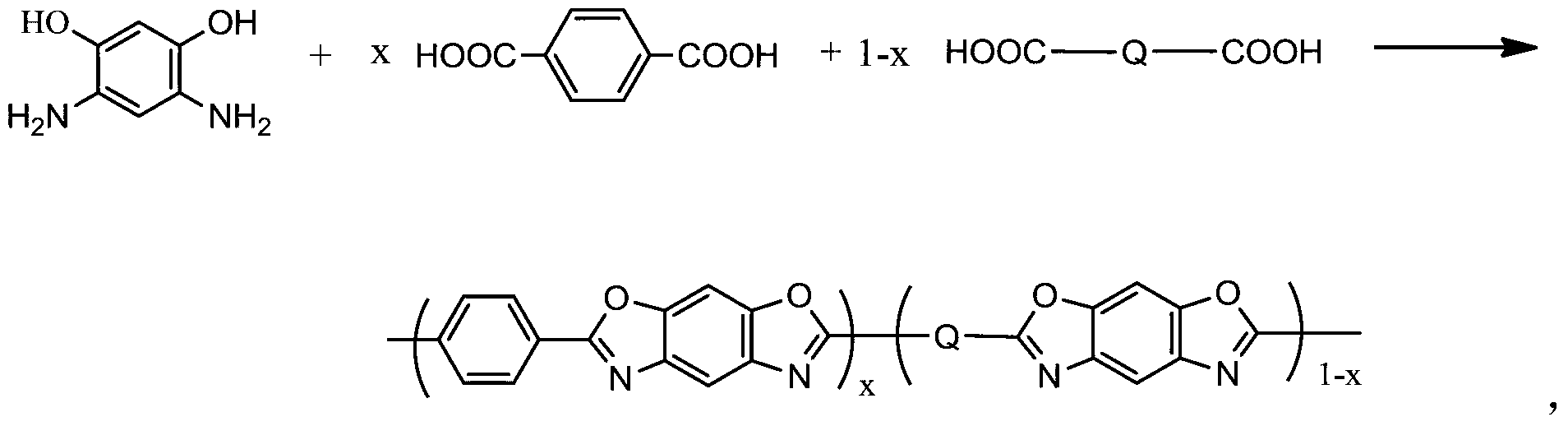

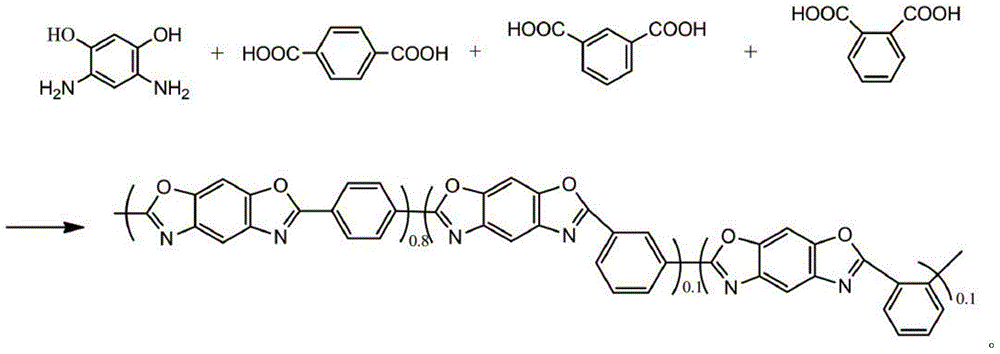

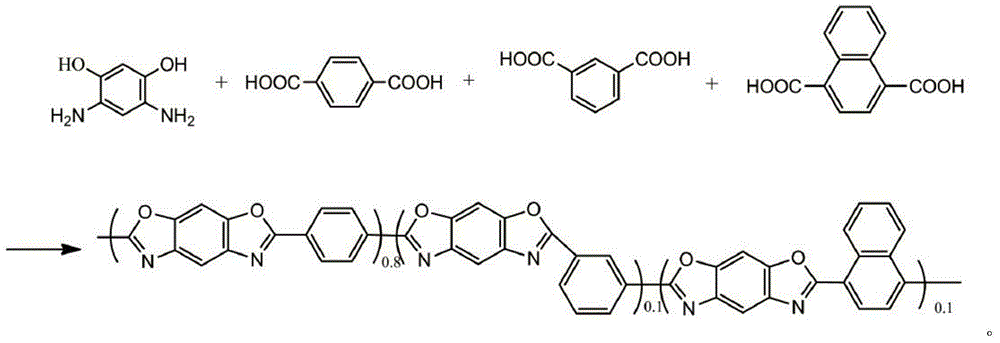

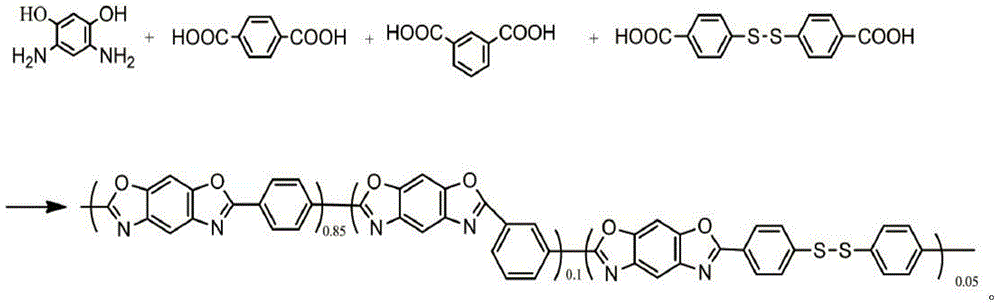

Preparation method of modified polybenzobisoxazole resin polymer

ActiveCN103304817AImprove thermal stabilityImprove thermal performanceMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method of a modified polybenzobisoxazole resin polymer. According to the preparation method, 8-12% of polyphosphoric acid (mass ratio) and 12-18% of phosphorus pentoxide (mass ratio) are added; the molar ratio of the molar sum of the added terephthalic acid and other diacid except the terephthalic acid of the residual mass ratio to 4,6-diamidoresorcinol is 1:1, wherein the molar content of terephthalic acid at least accounts for 80% of the total molar content of diacid; at least one of terephthalic acid and isophthalic acid is used for sure; the non-formic acid diacid is used or not, and the molar content does not exceed 10% of the total molar content of diacid if the non-formic acid diacid is used; and a conventional polybenzobisoxazole resin method is adopted for polymerization. The preparation method disclosed by the invention has the advantages that the strength of the fiber obtained by spinning by use of the polymer provided by the invention can exceed 3GPa, the viscosity of the spinning solution is greatly reduced, the equipment requirements in the spinning process are lowered, and the operation rate and production efficiency of the equipment in a production process are improved.

Owner:XUZHOU SILK FIBER TECH

Novel PP ultrathin thermal insulation shell fabric and production method thereof

InactiveCN105386221AReduce consumptionNothing producedWeft knittingTextile shapingFiberThermal insulation

The invention discloses a novel PP ultrathin thermal insulation shell fabric and a production method thereof. The production method comprises the steps that firstly, 75D or 8.3tex ultrafine-denier PP and novel 42D XLA comfortable and elastic fibers are interwoven; secondly, shaping and longitudinal and transverse drawing are performed at the temperature between 120 DEG C and 130 DEG C; thirdly, the dyeing and finishing process is performed; fourthly, processing and aftertreatment are performed. The shell fabric produced through the method is high in dimensional stability and heat loss and light and thin in texture, has the functions of keeping warm, being breathable, carrying anions and so on, is light and thin, soft in handfeel, good in fluffing and pilling resistance and light, attractive and comfortable to wear, can free people from past bloat in winter and achieves perfect combination of science and technology, fashion and functions, and the shrinkage rate is less than 2%.

Owner:GAOMI FUYUAN PRINTING & DYEING

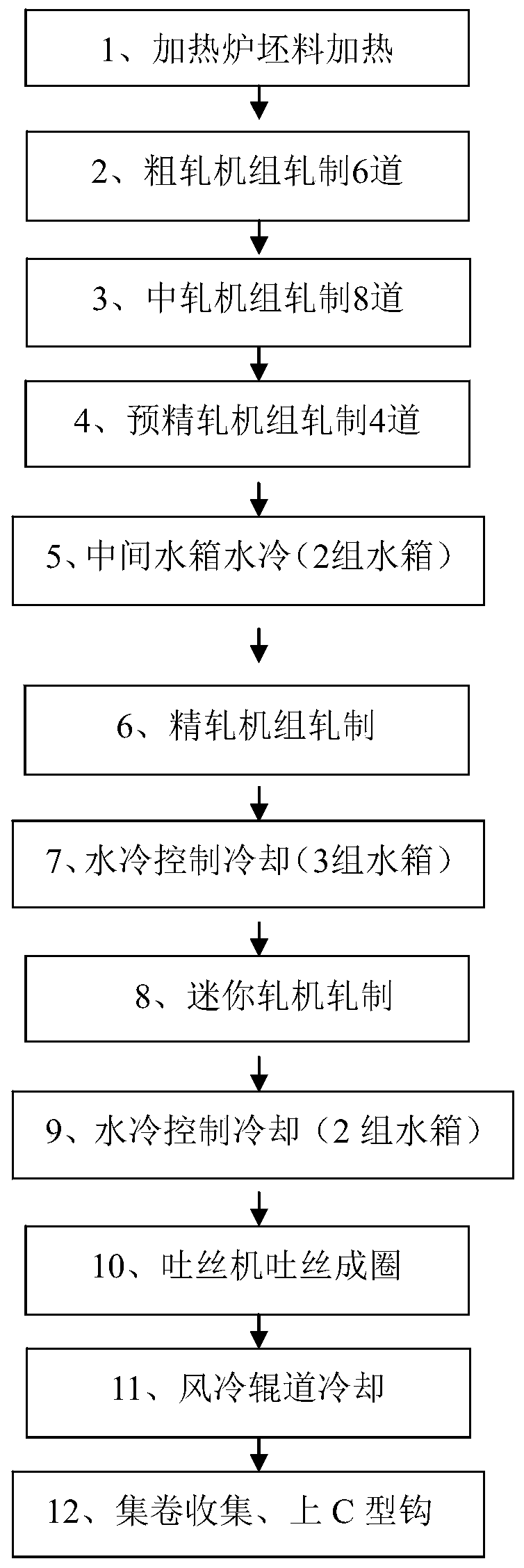

Production process of steel wire rod for producing prestress steel strand by utilizing mini-rolling mill

InactiveCN110238192ASuitable tensile strengthImprove plasticityTemperature control deviceWork treatment devicesPre stressMaterials science

The invention discloses a production process of a steel wire rod for producing a prestress steel strand by utilizing a mini-rolling mill. The equipment advantage of the mini-rolling mill is fully utilized, and the material for producing the prestress steel strand is developed and produced. According to the method, the rolling production process of a conventional prestress steel strand is broken through, technological parameter optimization measures such as the key temperature points of the mini-rolling mill and the spinning are groped and adjusted, the tensile strength, the grain size, the surface shrinkage and other comprehensive performances of the produced prestress steel strand material are obviously improved, and meanwhile aging time of the steel type is shortened.

Owner:ZENITH STEEL GROUP CORP

Use of pentaerythritol phosphate for improving flame retardancy and spinnability of nylon

ActiveCN108060465AWide variety of sourcesEasy to getFlame-proof filament manufactureMonocomponent polyamides artificial filamentPentaerythritolPhosphate

The invention provides a use of pentaerythritol phosphate for improving flame retardancy and spinnability of nylon. The nylon having addition of pentaerythritol phosphate and used as a raw material isused for spinning, and not only can the flame retardancy of nylon fibers be increased, but also the fluidity and rheology of the nylon in the spinning process are increased, so that the spinning temperature during molten spinning is greatly dropped, meanwhile, the spinning speed is increased, and thus the production efficiency is increased.

Owner:BEIJING INST OF CLOTHING TECH

Polyphenylene sulfide composite non-woven fabric as well as preparation method and application thereof

PendingCN113026212AGood compatibilityLower spinning temperatureNew-spun product collectionFibre typesEpoxyCompression molding

The invention relates to a polyphenylene sulfide composite non-woven fabric as well as a preparation method and application thereof, and belongs to the technical field of carbon fiber reinforced polyphenylene sulfide composite materials. The preparation method comprises the following steps of mixing polyphenylene sulfide, polyethersulfone and epoxy resin to prepare composite fibers, arranging the composite fibers into a net-shaped structure by using a winding machine, and then forming a PPS composite non-woven fabric which can be laid on the surface of the carbon fibers through setting. The preparation method has the beneficial effects that the epoxy resin can effectively improve the PPS / PES compatibility and reduce the PPS / PES spinning temperature in the early spinning process, the fracture toughness of the mixed thermoplastic resin is improved, the epoxy resin can be separated out in the later setting and net forming process, the heat resistance of the final thermoplastic composite material is not influenced, and the specific surface area of the prepared polyphenylene sulfide composite non-woven fabric is far higher than that of a polyphenylene sulfide film, so that carbon fibers can be rapidly infiltrated more easily in the compression molding process of a thermoplastic composite material.

Owner:上海碳纤维复合材料创新研究院有限公司

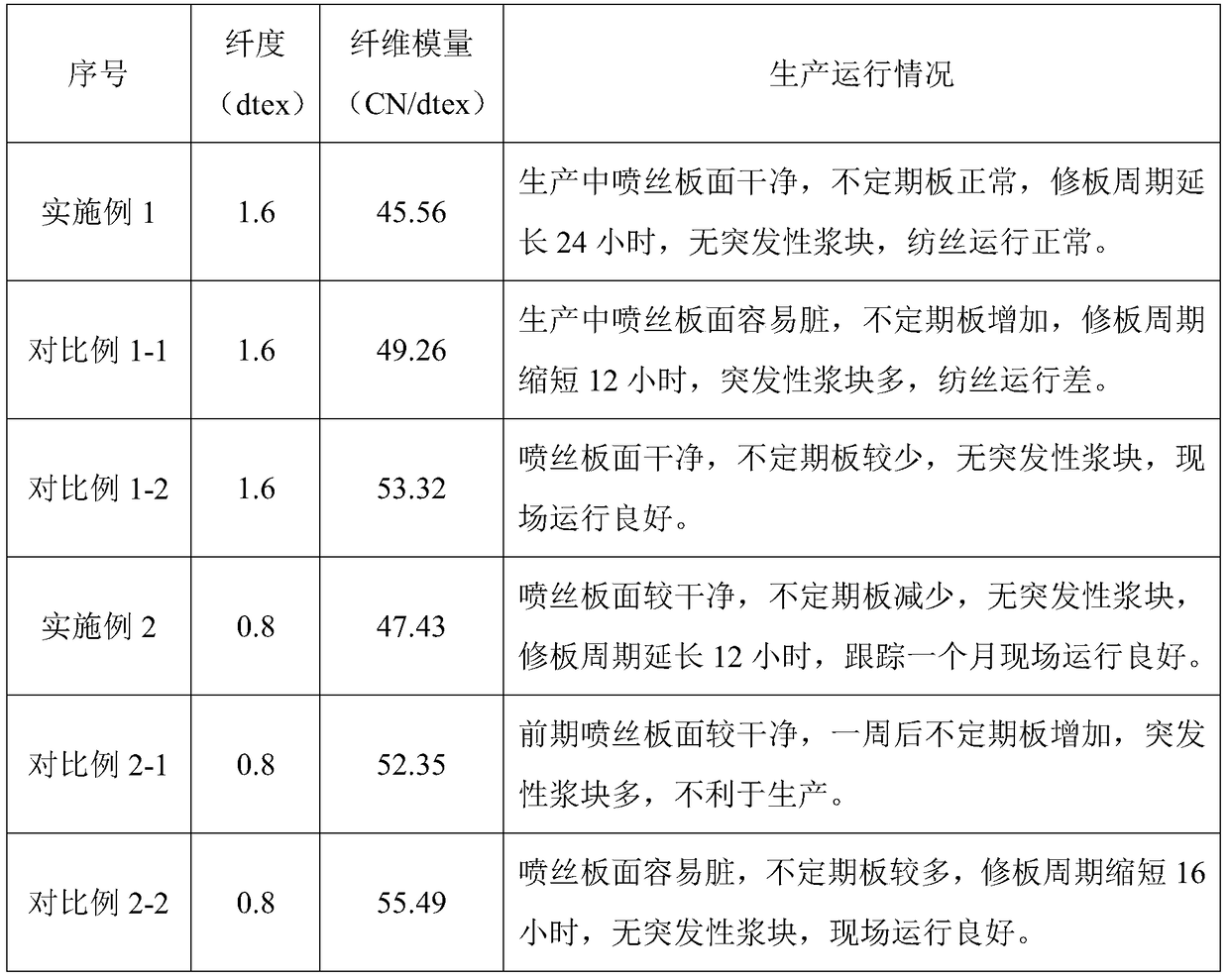

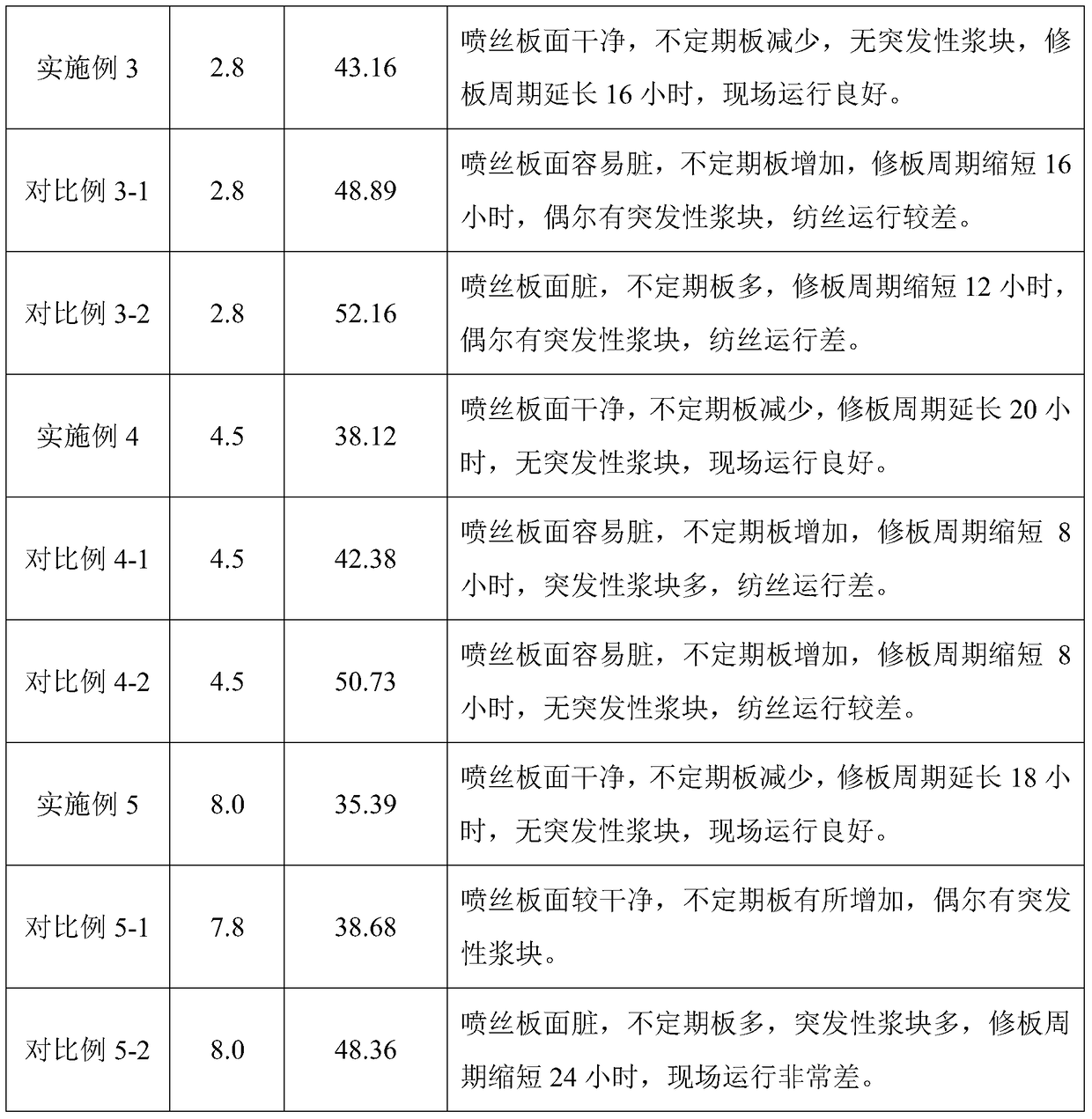

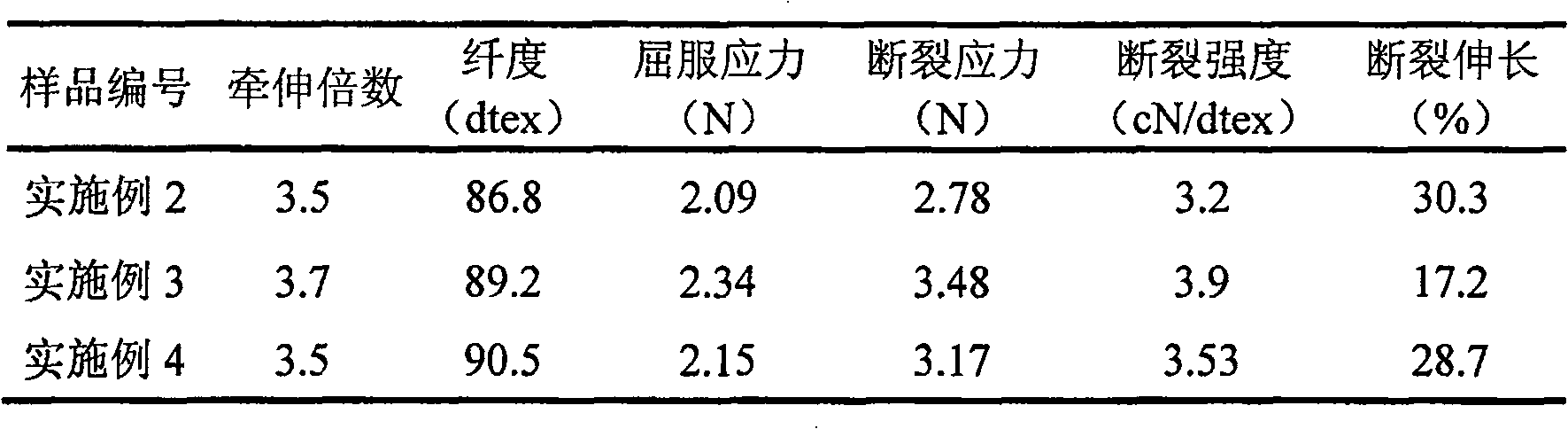

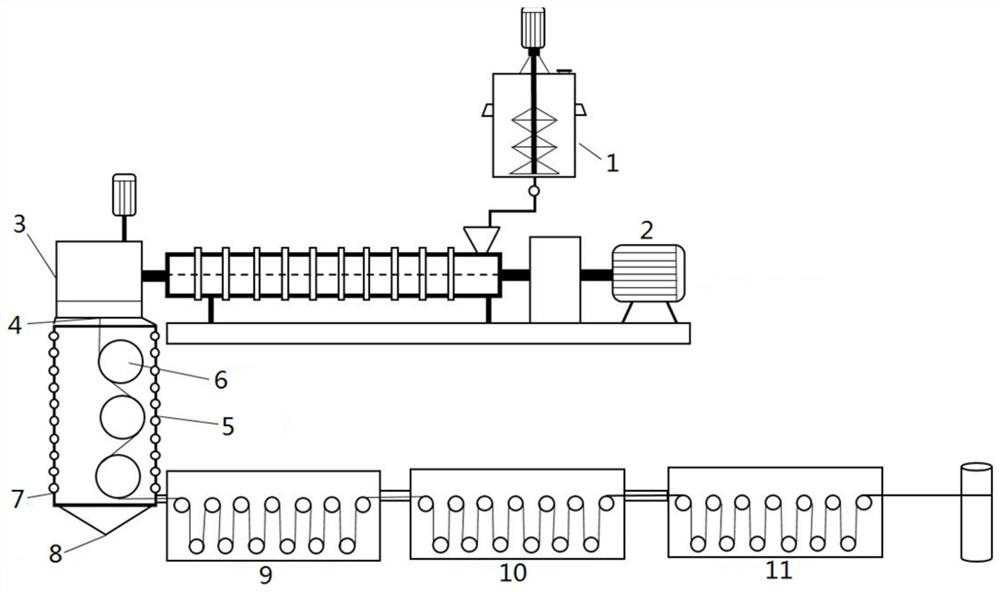

A kind of high flexibility environment-friendly staple fiber and preparation method thereof

ActiveCN106521683BLow modulusGood flexibilityArtificial filament heat treatmentMonocomponent copolyesters artificial filamentEnvironmental resistancePolyester

The invention discloses high-flexibility environmentally-friendly short fiber and a preparation method thereof, and the short fiber with the fiber modulus of 35-48CN / dtex and the fineness of 0.8dtex-8.0dtex is obtained by direct spinning of polyester synthesized by a titanium-containing catalyst. Compared with a conventional process, the polyester short fiber is produced by the titanium-containing catalyst, while maintaining of constant original indexes of the product, spinning temperature is reduced, improvement of adhesion between a polyester melt and a spinneret plate capillary pore tube wall is facilitated, melt slippage on the wall can be avoided, unstable melt flow is induced, melt fracture is caused, and spinning hard wires and pulp bolts are generated. At the same time, aiming at a titanium melt, the spinning speed and the draw ratio are optimized to reduce the fiber modulus, production is normal, finished fiber is soft and plump in hand feeling, and fiber flexibility is further improved.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Modified polyphenylene sulfide fiber and method for making same

InactiveCN100567601CHigh glossImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceSilicon oxide

The invention provides a modified polyphenylene sulfide fiber and a preparation method thereof. The components and parts by weight include: 100 parts of polyphenylene sulfide (PPS); 0.2 to 2 parts of nano silicon dioxide after surface treatment, two The particle size of silicon oxide is 20-60 nanometers; the fineness of the fiber is 85-91dtax. The present invention modifies the polyphenylene sulfide resin and adopts a specific spinning process to prepare polyphenylene sulfide fiber, the fiber strength and tensile toughness are improved, and the glossiness of the fiber is also improved at the same time. The spinning equipment is used for spinning, which reduces the spinning cost, and the fluidity of the matrix becomes better during the spinning process, the spinning temperature is reduced by 5-10°C, the draft ratio of the primary fiber is improved, and the mechanical properties of the fiber Improved.

Owner:DONGHUA UNIV

Imitated nylon modified fibre of dyeable polypropylene

InactiveCN101333691BImprove liquidityImprove flexibilityMonocomponent polyolefin artificial filamentArtifical filament manufactureEthyleneDyeing

The invention relates to an imitated nylon differential fiber of dyeable polypropylene fiber for dyeing, which comprises: 80 to 90 percent of polypropylene, 9 to 11 percent of dyeable master batch, 0.3 to 0.7 percent of cooling auxiliary agent and 4.0 to 5.0 percent of polyethylene. The fiber has the advantages that: firstly, the polypropylene fiber has the flexibility, tensile property and elasticity as nylon through modifying the polypropylene fiber; and secondly, the dyeability of the modified polypropylene fiber is realized.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

A kind of preparation method of environment-friendly high-strength high-modulus polyethylene fiber

ActiveCN110079881BBig pollutionSmall mechanical propertiesArtificial filament heat treatmentMonocomponent polyolefin artificial filamentPolymer scienceSpinning

The invention relates to a preparation method of environment-friendly high-strength and high-modulus polyethylene fiber. The spinning solution is prepared by mixing ultra-high molecular weight polyethylene resin and decahydronaphthalene according to a certain ratio, and enters into a twin-screw extruder and a spinning box after swelling treatment. After being extruded from the spinneret, it enters the constant temperature box, and after being cooled and shaped by the cold roll in the constant temperature box, it enters the multi-stage hot roll drying device, and finally is stretched and wound by the traction hot roll. The strength of the fiber prepared by the present invention can reach 40cN / dtex and above, and the modulus is 1800cN / dtex and above. Compared with the traditional spinning method, it has the advantages of short process, energy saving and environmental protection, no secondary solvent introduction post-treatment and uniform fiber fineness, etc. Features, the prepared fibers can be used to prepare bulletproof vests, bulletproof helmets, protective armor, high-strength marine cables, cut-resistant gloves, mats, arm guards, etc.

Owner:SHANGHAI RES INST OF CHEM IND

Hollow fiber film and method for producing the same

InactiveCN101322922BIncrease elasticityIncrease water fluxSemi-permeable membranesMembranesSolventHeating temperature

The invention relates to a hollow fiber membrane and a manufacturing method thereof. The weight percentage prescription of the membrane forming system of the membrane is: 25 to 45 percent of polyurethane; 35 to 60 percent of compound pore-forming agent; 15 to 20 percent of organic low molecular; the sum of each component is 100 percent; wherein, the polyurethane is a fiber grade; the weight ratioof a hard section and a soft section is 1 / 1 to 1 / 5; the compound pore-forming agent is the mixture of an interface cavity pore-forming agent and a non-interface cavity pore-forming agent; the organiclow molecular liquid is a good water-soluble polyurethane solvent with a high boiling point; the manufacturing method of the membrane adopts the following melt spinning technique: firstly the prescription of the invention demands the preparation of a polymer membrane forming system; then the polymer membrane forming system is poured into a mixing tank to carry out heating, reinforcing and pre-mixing with a heating temperature of 130 to 140 DEG C; the polymer membrane forming system is injected into a double screw extruder after being uniformly mixed; melt blending spinning is carried out to manufacture the membrane under the temperature of 130 to 155 DEG C; then the hollow fiber membrane is obtained after the normal working procedure of water extraction washing.

Owner:TIANJIN POLYTECHNIC UNIV

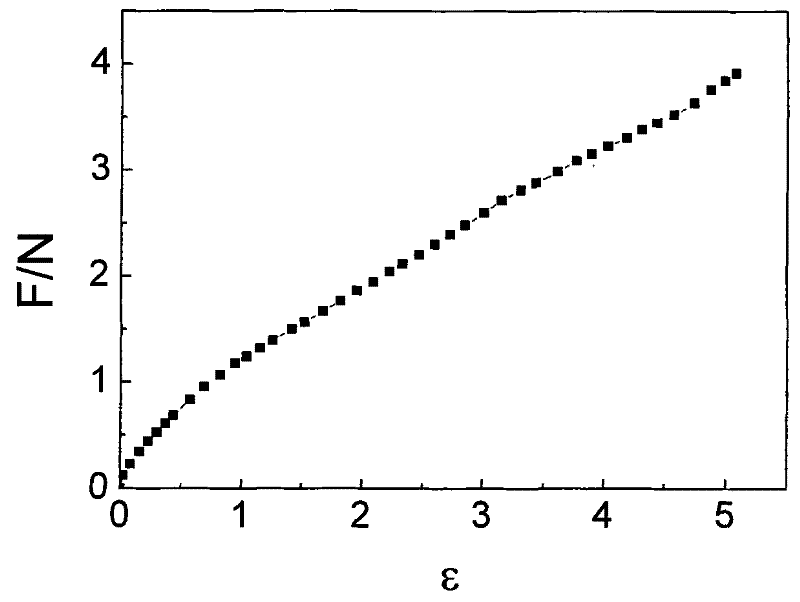

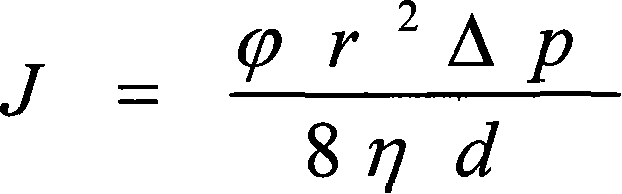

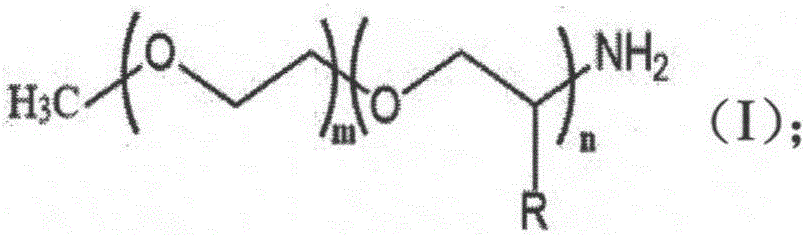

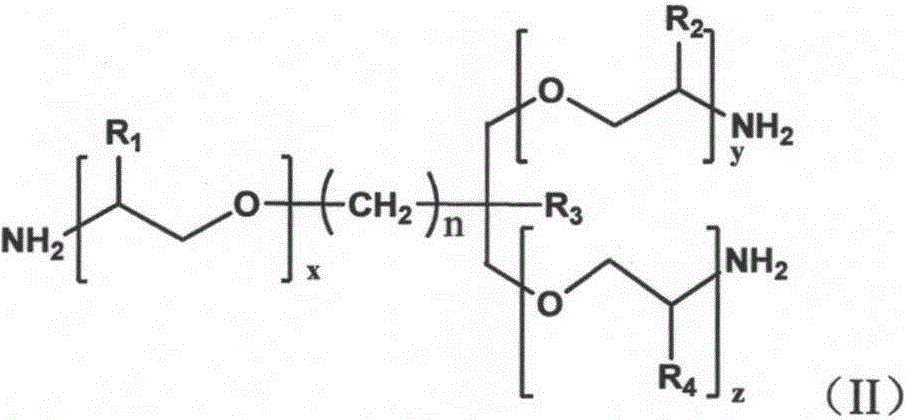

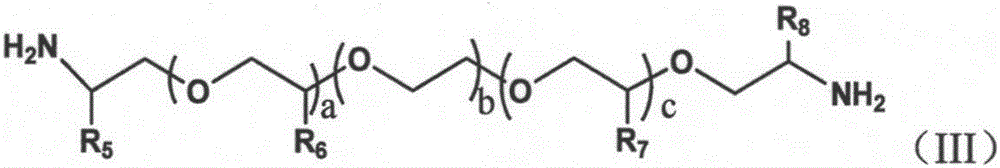

Polyester fiber and preparation method thereof

InactiveCN105821512AHigh tensile strengthResin intrinsic viscosity changes littleSpinning head liquid feederFilament/thread formingChemistryPolyester

The invention provides a polyester fiber and a preparation method thereof. The polyester fiber is characterized by containing polyester and amino terminated polyether, wherein the content of the amino terminated polyether is 0.1-10% of the polyester mass. The polyester fiber has the advantages of high intrinsic viscosity, high fiber strength, excellent color and luster, low costs and the like. The preparation method of the polyester fiber has the advantages that a process is simple, spinning temperature is low, the intrinsic viscosity change of resin is small before and after spinning, and the like.

Owner:DONGHUA UNIV

Use of pentaerythritol phosphate for improving flame retardancy and spinnability of nylon

ActiveCN108060465BWide variety of sourcesEasy to getFlame-proof filament manufactureMonocomponent polyamides artificial filamentPolymer sciencePentaerythritol

The invention provides a use of pentaerythritol phosphate for improving flame retardancy and spinnability of nylon. The nylon having addition of pentaerythritol phosphate and used as a raw material isused for spinning, and not only can the flame retardancy of nylon fibers be increased, but also the fluidity and rheology of the nylon in the spinning process are increased, so that the spinning temperature during molten spinning is greatly dropped, meanwhile, the spinning speed is increased, and thus the production efficiency is increased.

Owner:BEIJING INST OF CLOTHING TECH

A kind of preparation method of modified polybenzobisoxazole resin polymer

ActiveCN103304817BImprove thermal stabilityImprove thermal performanceMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method of a modified polybenzobisoxazole resin polymer. According to the preparation method, 8-12% of polyphosphoric acid (mass ratio) and 12-18% of phosphorus pentoxide (mass ratio) are added; the molar ratio of the molar sum of the added terephthalic acid and other diacid except the terephthalic acid of the residual mass ratio to 4,6-diamidoresorcinol is 1:1, wherein the molar content of terephthalic acid at least accounts for 80% of the total molar content of diacid; at least one of terephthalic acid and isophthalic acid is used for sure; the non-formic acid diacid is used or not, and the molar content does not exceed 10% of the total molar content of diacid if the non-formic acid diacid is used; and a conventional polybenzobisoxazole resin method is adopted for polymerization. The preparation method disclosed by the invention has the advantages that the strength of the fiber obtained by spinning by use of the polymer provided by the invention can exceed 3GPa, the viscosity of the spinning solution is greatly reduced, the equipment requirements in the spinning process are lowered, and the operation rate and production efficiency of the equipment in a production process are improved.

Owner:XUZHOU SILK FIBER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com