Use of pentaerythritol phosphate for improving flame retardancy and spinnability of nylon

A technology of pentaerythritol phosphate and flame retardancy, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyamide artificial filaments, etc., which can solve the problems of easy broken filaments, burrs, hindering the application of nylon, and reducing the spinnability of nylon And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

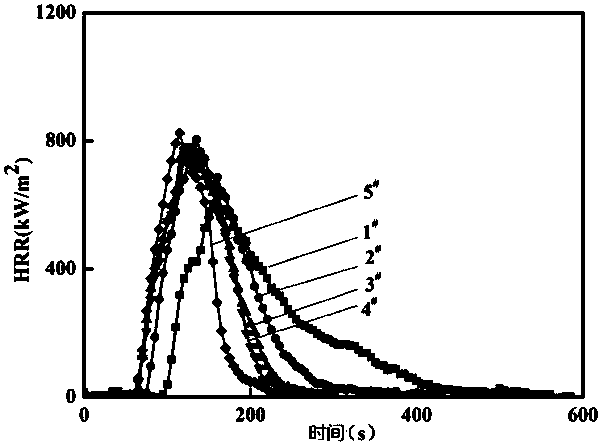

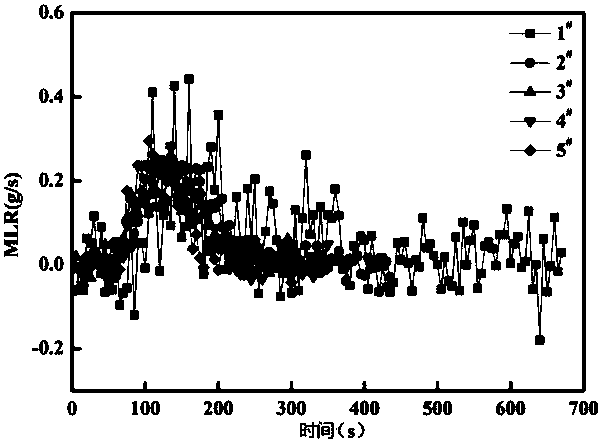

Examples

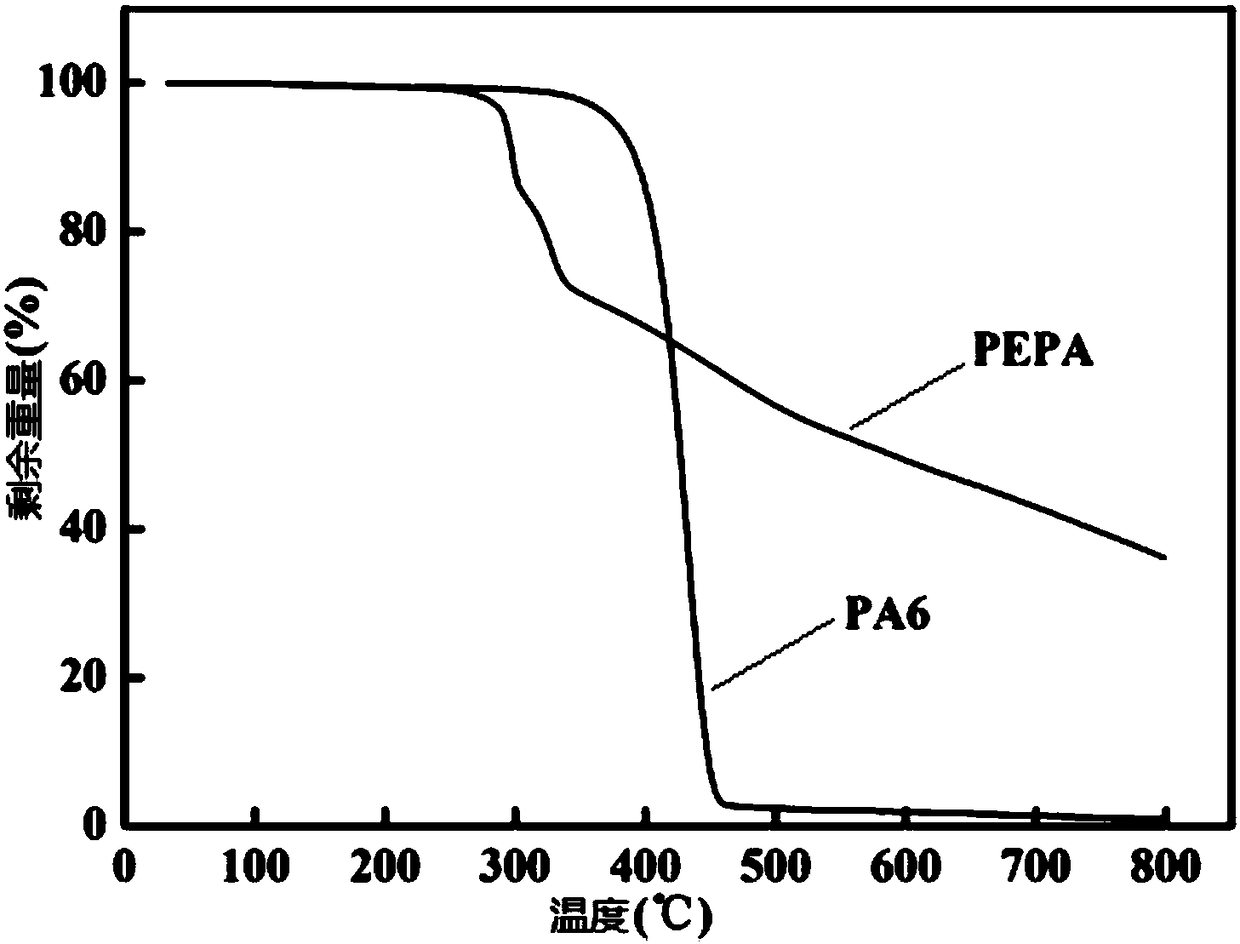

Embodiment 1

[0077] PA6 slices were vacuum-dried at 100°C for 12 hours, and PEPA was dried in a blast drying oven at 100°C for 2 hours. 950g of PA6 slices and 50g of PEPA samples were melt-blended and extruded through a melt spinning machine, and cooled with water at room temperature to obtain PA6 / PEPA resistance. Burning nylon masterbatch casting belt. The temperature of each zone of the extruder is set at 180-235-235-230° C., and the screw speed is 30 rpm.

[0078] After the extruded PA6 / PEPA flame-retardant nylon masterbatch was cast into pellets, it was vacuum-dried at 100°C for 10 hours, and was injected into the standard sample to be tested in HAKEE MINI JET of Thermo Scientific Company in the United States. The injection temperature was 235°C and the mold temperature was 40°C, injection molding pressure 400bar, to obtain flame retardant nylon masterbatch.

Embodiment 2

[0080] The method used in this embodiment is similar to that of Example 1, except that the weight of the PA6 chips is 900 g, and the weight of the PEPA is 100 g, so as to obtain the flame-retardant nylon masterbatch.

Embodiment 3

[0082] The method used in this embodiment is similar to that of Example 1, except that the weight of PA6 chips is 850 g, and the weight of PEPA is 150 g, so as to obtain the flame-retardant nylon masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com