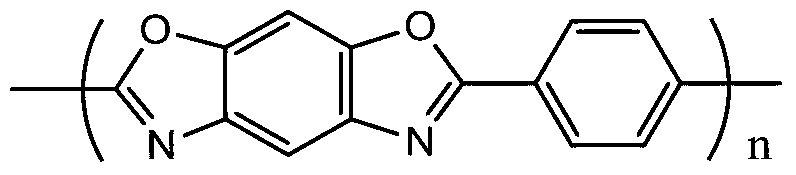

Preparation method of modified polybenzobisoxazole resin polymer

A benzobisoxazole and polymer technology, which is applied in the field of preparation of modified polybenzobisoxazole resin polymers, can solve problems such as poor operation stability, liquid return, and difficult filtration, and achieve improved fiber uniformity , the viscosity of the system is reduced, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

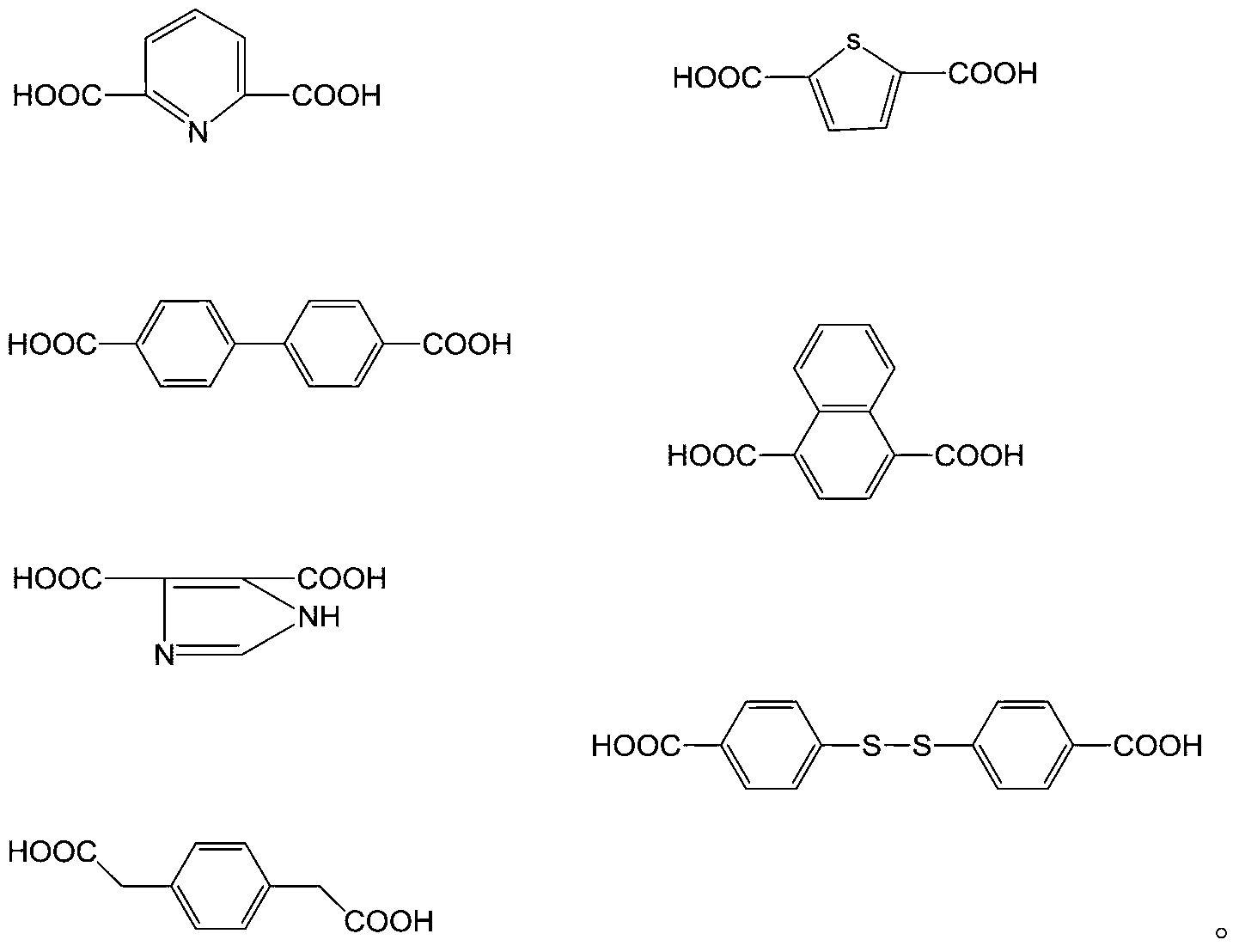

[0052] The 1660g of terephthalic acid in the comparative example was replaced with 1328g of terephthalic acid, 166g of phthalic acid, and 166g of isophthalic acid. The contents of other reactants and the polymerization process were the same as those of the comparative example. The spinning conditions are: spinning pressure 10 MPa, spinning temperature 170°C.

[0053] In the modified resin, the content of terephthalic acid structural unit is 0.8 (molar content, the same below), and the content of phthalic acid and isophthalic acid structural unit is both 0.1.

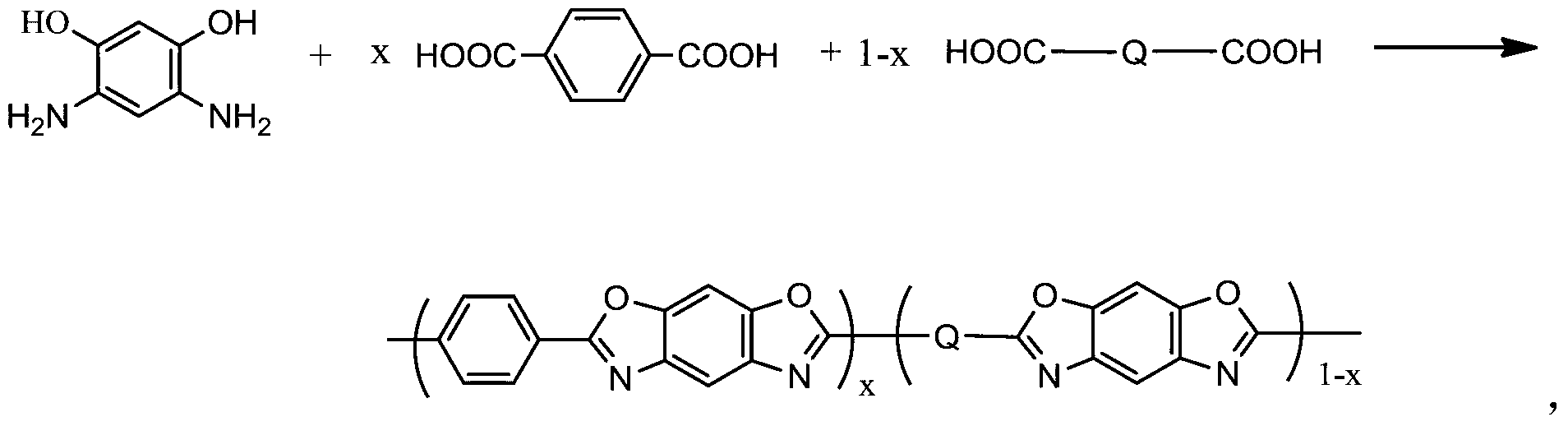

[0054] Its reaction formula is as follows:

[0055]

[0056] The modified polybenzoxazole fiber obtained in this embodiment has an initial thermal decomposition temperature of 589° C., a strength of 4.1 GPa, and an unevenness rate of 8.9%.

Embodiment 2

[0058] The 1660g terephthalic acid in the comparative example was replaced with 1494g terephthalic acid and 166g isophthalic acid, and the contents of other reactants and the polymerization process were the same as the comparative example. The spinning conditions are: spinning pressure 12MPa, spinning temperature 173°C.

[0059] In the modified resin, the content of the terephthalic acid structural unit is 0.9, and the content of the isophthalic acid structural unit is 0.1.

[0060] Its reaction formula is as follows:

[0061]

[0062] The modified polybenzoxazole fiber obtained in this embodiment has an initial thermal decomposition temperature of 594° C., a strength of 5.3 GPa, and an unevenness rate of 9.7%.

Embodiment 3

[0064] The 1660g of terephthalic acid in the comparative example was replaced with 1328g of terephthalic acid, 166g of phthalic acid, and 216g of naphthalene dicarboxylic acid, and the contents of other reactants and the polymerization process were the same as those of the comparative example. The spinning conditions are: spinning pressure 11 MPa, spinning temperature 175°C.

[0065] In the modified resin, the content of the structural unit of terephthalic acid is 0.8, and the content of the structural units of phthalic acid and naphthalene dicarboxylic acid are both 0.1.

[0066] Its reaction formula is as follows:

[0067]

[0068] The modified polybenzoxazole fiber obtained in this embodiment has an initial thermal decomposition temperature of 591° C., a strength of 4.7 GPa, and an unevenness rate of 8.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com