Preparation method of environment-friendly high-strength high-modulus polyethylene fibers

A polyethylene fiber, high-strength and high-modulus technology, applied in the preparation of spinning solution, single-component polyolefin rayon, drawing spinning, etc., can solve the problems of unfavorable green spinning industry development, unfavorable sustainable Serious environmental pollution and other problems, to achieve the effect of short spinning process, increased stretchability, and good fiber uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

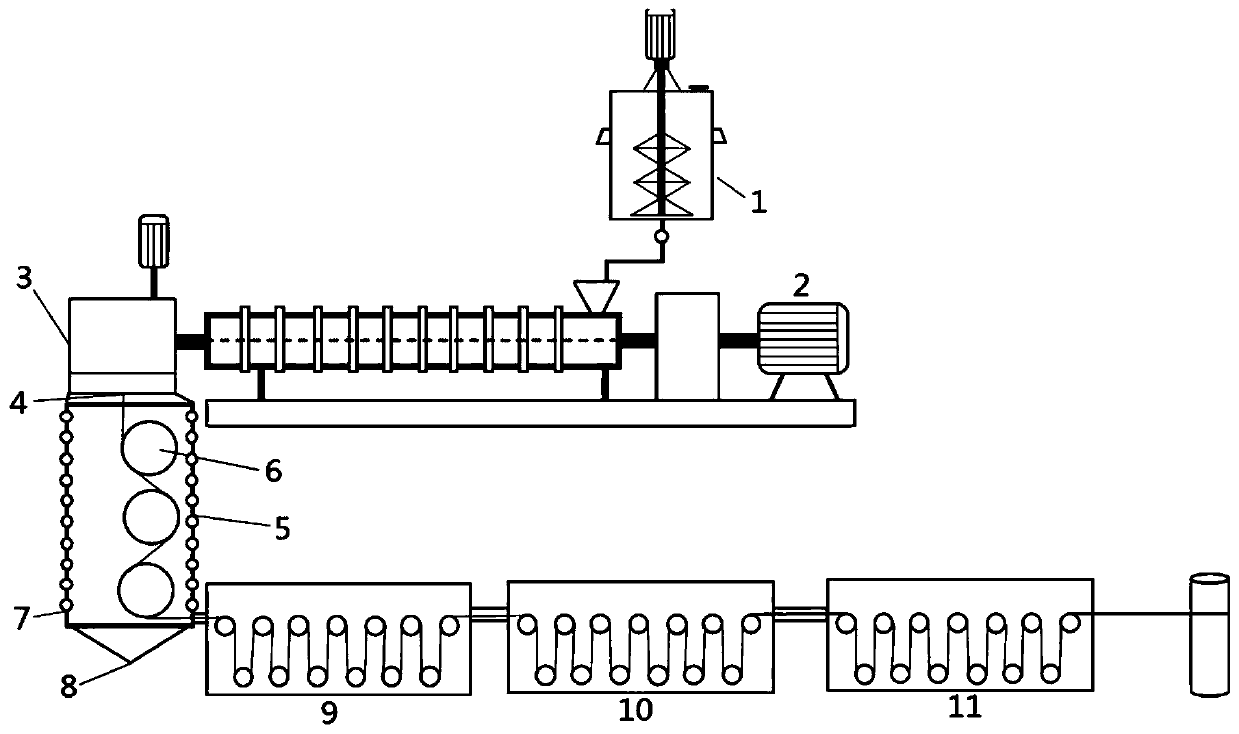

[0021] A kind of preparation method of environment-friendly high-strength high-modulus polyethylene fiber, its technological process is as follows figure 1 As shown, it is prepared by mixing ultra-high molecular weight polyethylene resin with a viscosity average molecular weight of 1 million to 8 million and decahydronaphthalene with a cis-trans ratio of 1:9 to 9:1 in a mass ratio of 1:50 to 1:4. Spinning solution, in the swelling kettle 1, control the temperature at 60-125°C, swell for 0-6 hours, and then enter the screw extruder 2, the screw extruder adopts parallel co-rotating twin-screws, counter-rotating twin-screws, Type three-screw or pin-shaped three-screw, the length-to-diameter ratio of the screw is 40:1~80:1, the diameter of the screw is 20mm~150mm, the highest temperature in the screw area is 150~250°C for extrusion processing, and then through the spinning box 3, by Spinneret 4 enters thermostat 5 after being extruded, and thermostat 5 is made up of cooling coil 7...

Embodiment 1

[0024] Select ultra-high molecular weight polyethylene resin with a molecular weight of 6 million, decahydronaphthalene cis-trans ratio 1:9, mix and prepare a spinning solution with a mass percentage of 6wt%, pre-swell at 90°C for 2 hours, and then enter parallel twin-screw extrusion Out of the machine, the maximum temperature in the screw area is set at 190°C, the diameter of the parallel twin-screw is 35mm, the aspect ratio is 68, the temperature of the thermostat and the cold roll is set at -10°C, the drying temperature of the first-stage hot roll is 100°C, and the drying temperature of the second-stage hot roll is 80°C, the temperature of the drafting hot roller is 140°C, and the total draw ratio is 120 times. The index of the prepared fiber is as follows: denier 400D, breaking strength 42cN / dtex, modulus 1990cN / dtex.

Embodiment 2

[0026] Select ultra-high molecular weight polyethylene resin with a molecular weight of 4.5 million, decahydronaphthalene cis-trans ratio of 2:8, mix and prepare a spinning solution with a mass percentage of 6wt%, pre-swell at 90°C for 2 hours, and then enter parallel twin-screw extrusion Out of the machine, the maximum temperature in the screw area is set at 200°C, the diameter of the parallel twin-screw is 35mm, the aspect ratio is 68, the temperature of the thermostat and the cold roll is set at -10°C, the drying temperature of the first-stage hot roll is 100°C, and the drying temperature of the second-stage hot roll is 80°C, the temperature of the drafting hot roller is 140°C, and the total draw ratio is 120 times. The index of the prepared fiber is as follows: denier 400D, breaking strength 41cN / dtex, modulus 1860cN / dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com