Technical method and facilites for loading and unloading goods at berth in hundred thousand tunnage

A process method and berth technology, which is applied in the field of port berth loading and unloading, can solve the problems of low loading and unloading transportation efficiency, easy scattering of bulk goods to the work site, and pollution of the work environment, so as to reduce the cost of mechanical lubrication and protection and improve the efficiency of bulk ore operations , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

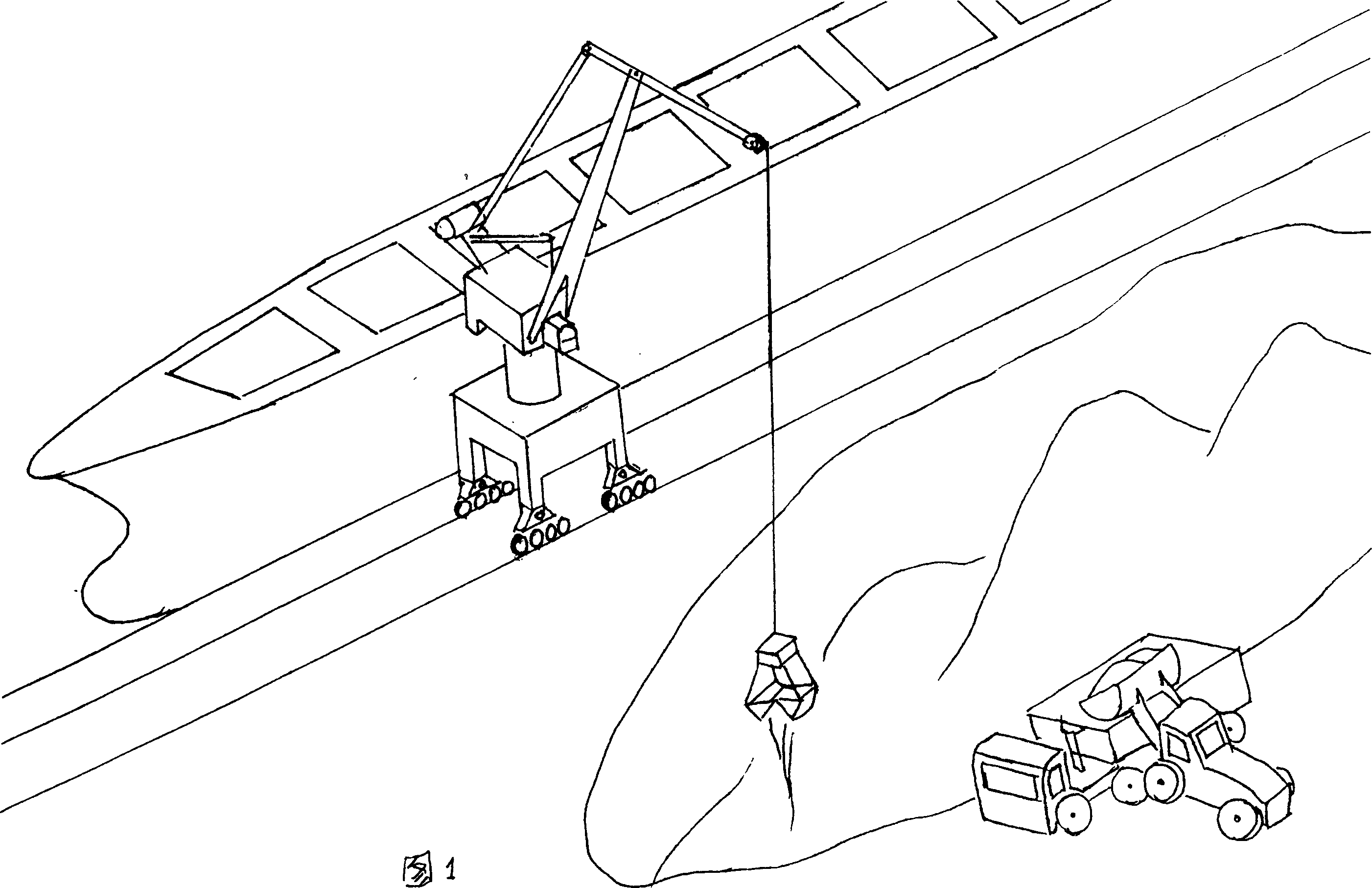

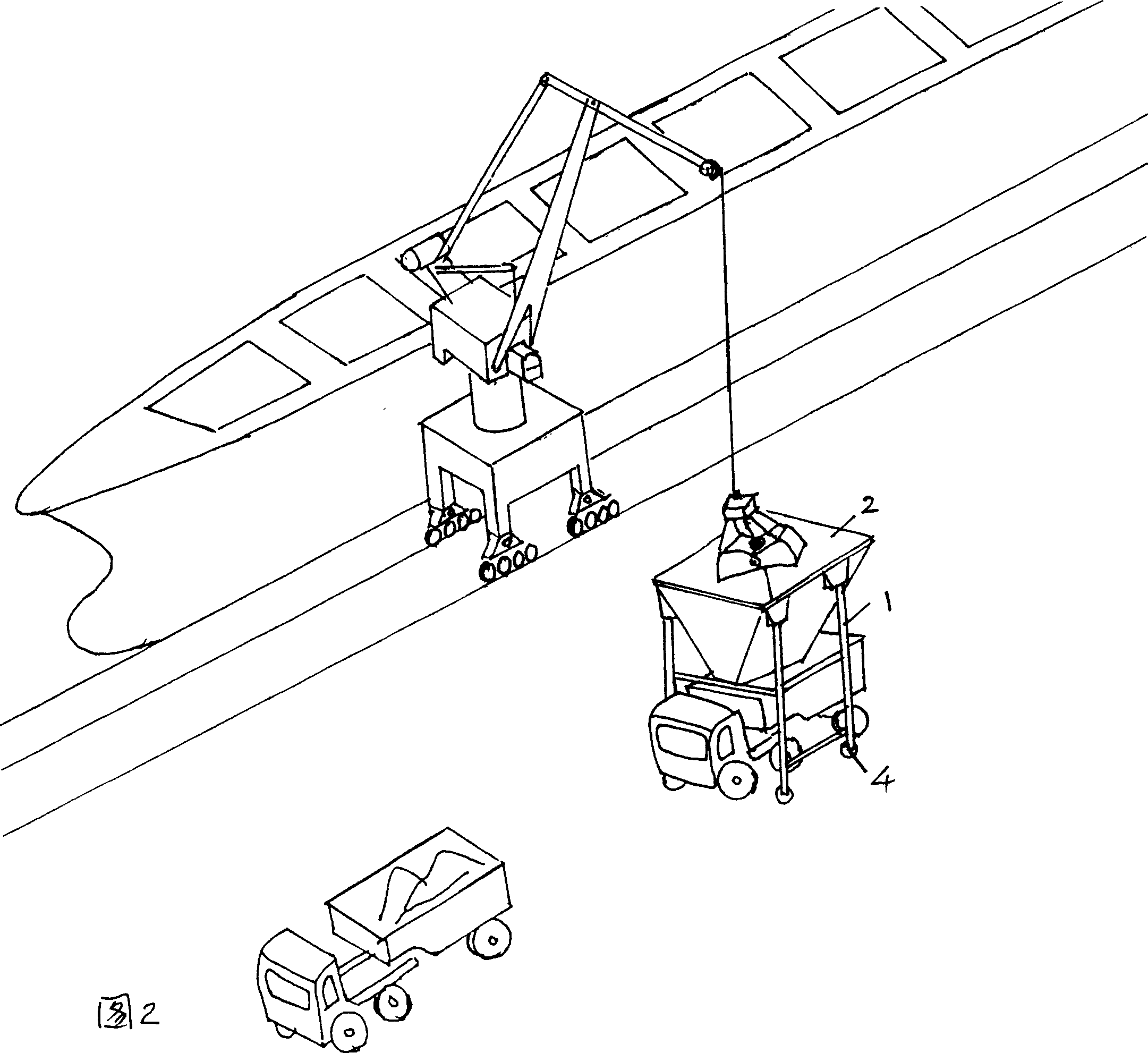

[0033] Figure 2 shows a 100,000-ton berth loading and unloading process. The bulk cargo in the cabin is hoisted by the grab of a large crane to a special hopper machine installed above the car, and the grab is directly loaded through the hopper of the hopper machine. to the car.

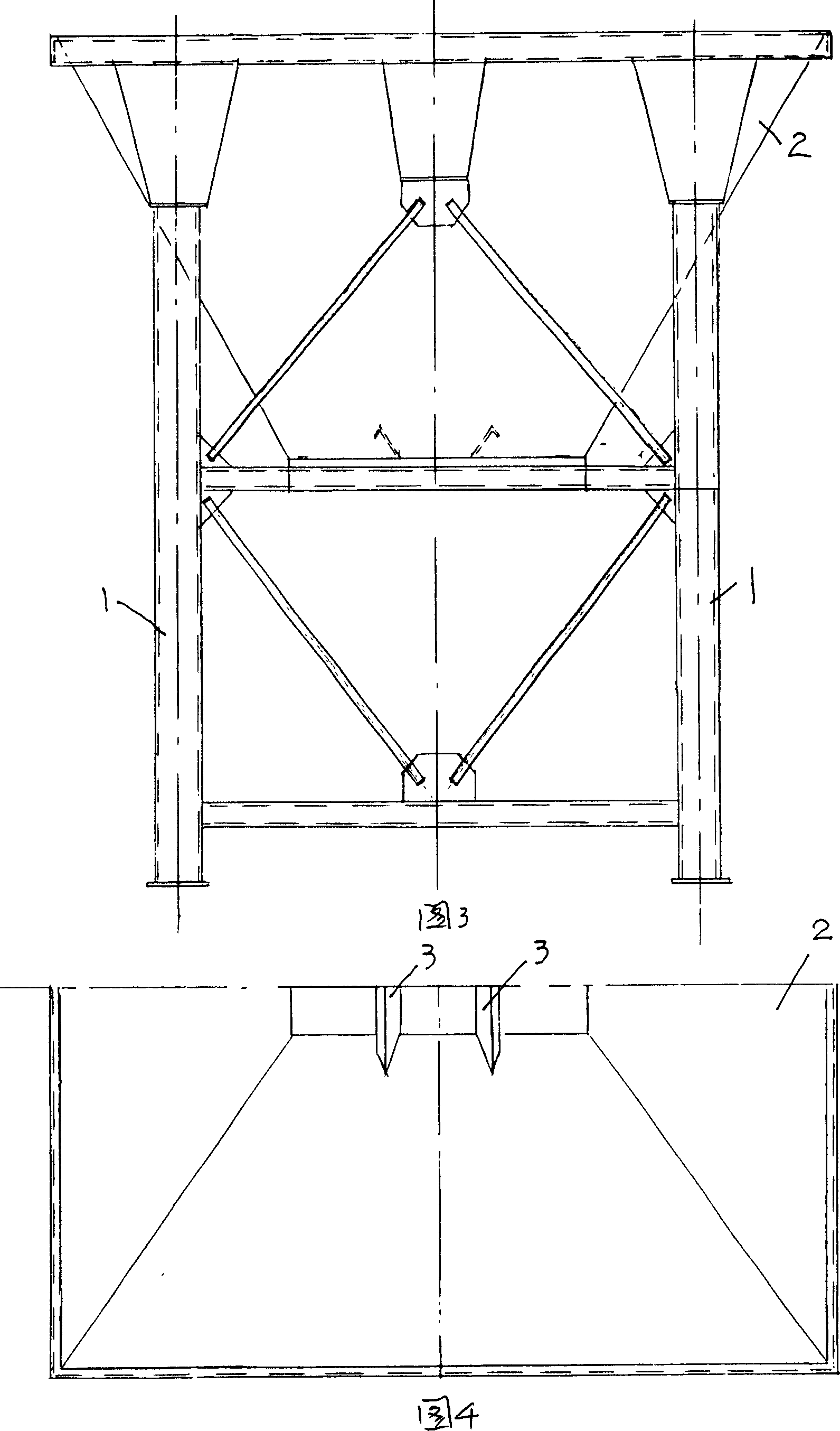

[0034] The equipment used in a kind of 100,000-ton berth loading and unloading process shown in Fig. 3 and 4 has a four-column support 1, and a large funnel 2 is housed on the top of the support.

[0035] There is a diaphragm guide plate 3 at the bottom of the big funnel.

[0036] Large casters 4 can be installed under the feet of the four-column support.

[0037] The bulk ore loading and unloading process after optimized design is as follows: the bulk cargo of the bulk cargo ship is directly loaded into the car by the grab bucket of the large gantry crane through the special funnel, and directly transported to the rear storage yard and then loaded into the train or car by the loader .

[0038] At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com