Polyester fiber and preparation method thereof

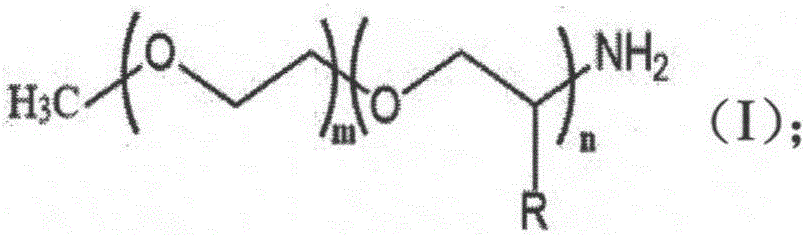

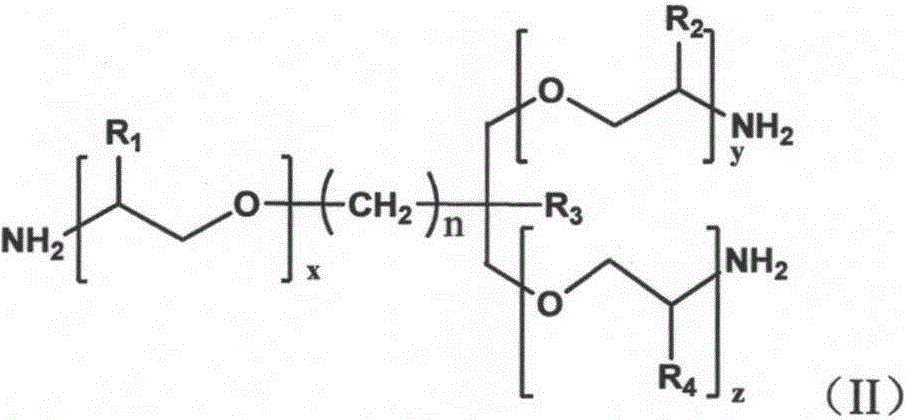

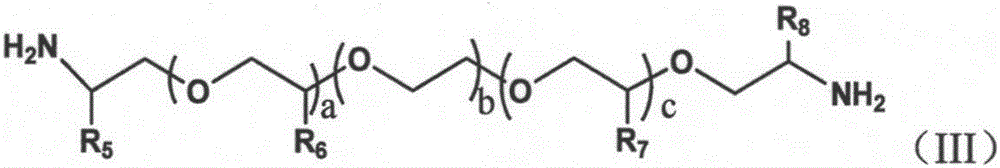

A polyester fiber and polyester technology, which is applied to polyester fibers containing amine-terminated polyether compounds and their preparation, in the field of polyester fibers, can solve the problems of fiber performance deterioration and molecular weight reduction, and achieve high tensile strength. , low cost, high fiber strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A polyester fiber comprising polyester A and amino-terminated polyether a, wherein the content of amino-terminated polyether a is 0.2% of the polyester A quality, and its preparation method is:

[0062] In an inert gas flow (N 2 ), the polyester A is introduced into the main feed port of the screw extruder at a rate of 1kg / h, and the amino-terminated polyether a is introduced into the side feed port of the screw extruder at a rate of 2g / h. Polyester A and amino-terminated polyether a are mixed in a screw extruder. The obtained mixture is input into the raw material cavity of the spinning machine, and the melt is extruded through the spinneret at 290° C. to form fiber bundles to obtain smooth raw silk. The tensile strength of monofilament measured by stretching is 5.8cN / dtex, and the intrinsic viscosity is 0.66dl / g.

Embodiment 2

[0064] A polyester fiber comprising polyester B and amino-terminated polyether a, wherein the content of amino-terminated polyether a is 0.5% of the polyester B quality, and its preparation method is:

[0065] In an inert gas flow (N 2 ), the polyester B is introduced into the main feed port of the screw extruder at a rate of 1kg / h, and the amino-terminated polyether a is introduced into the side feed port of the screw extruder at a rate of 5g / h. Polyester B and amino-terminated polyether a were mixed in an extruder. The obtained mixture is input into the raw material cavity of the spinning machine, and the melt is extruded through the spinneret at 295° C. to form fiber bundles to obtain smooth raw filaments. The tensile strength of monofilament measured by stretching is 7.1cN / dtex, and the intrinsic viscosity is 0.98dl / g.

Embodiment 3

[0067] A polyester fiber comprising polyester C and amino-terminated polyether a, wherein the content of amino-terminated polyether a is 1% of the quality of polyester C, and its preparation method is:

[0068] In an inert gas flow (N 2 ), the polyester C is introduced into the main feed port of the screw extruder at a rate of 1kg / h, and the amino-terminated polyether a is introduced into the side feed port of the screw extruder at a rate of 10g / h. Polyester C and amino-terminated polyether a are mixed in an extruder. The obtained mixture is input into the raw material cavity of the spinning machine, and the melt is extruded through the spinneret at 295° C. to form fiber bundles to obtain smooth raw filaments. The tensile strength of monofilament measured by stretching is 7.4cN / dtex, and the intrinsic viscosity is 1.11dl / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Monofilament tensile strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com