A kind of high flexibility environment-friendly staple fiber and preparation method thereof

A technology of short fiber and flexibility, which is applied in the field of polyester fiber and its preparation, can solve the problems that have not been developed accordingly, and achieve the effect of soft and plump hand feeling, avoiding slippage, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

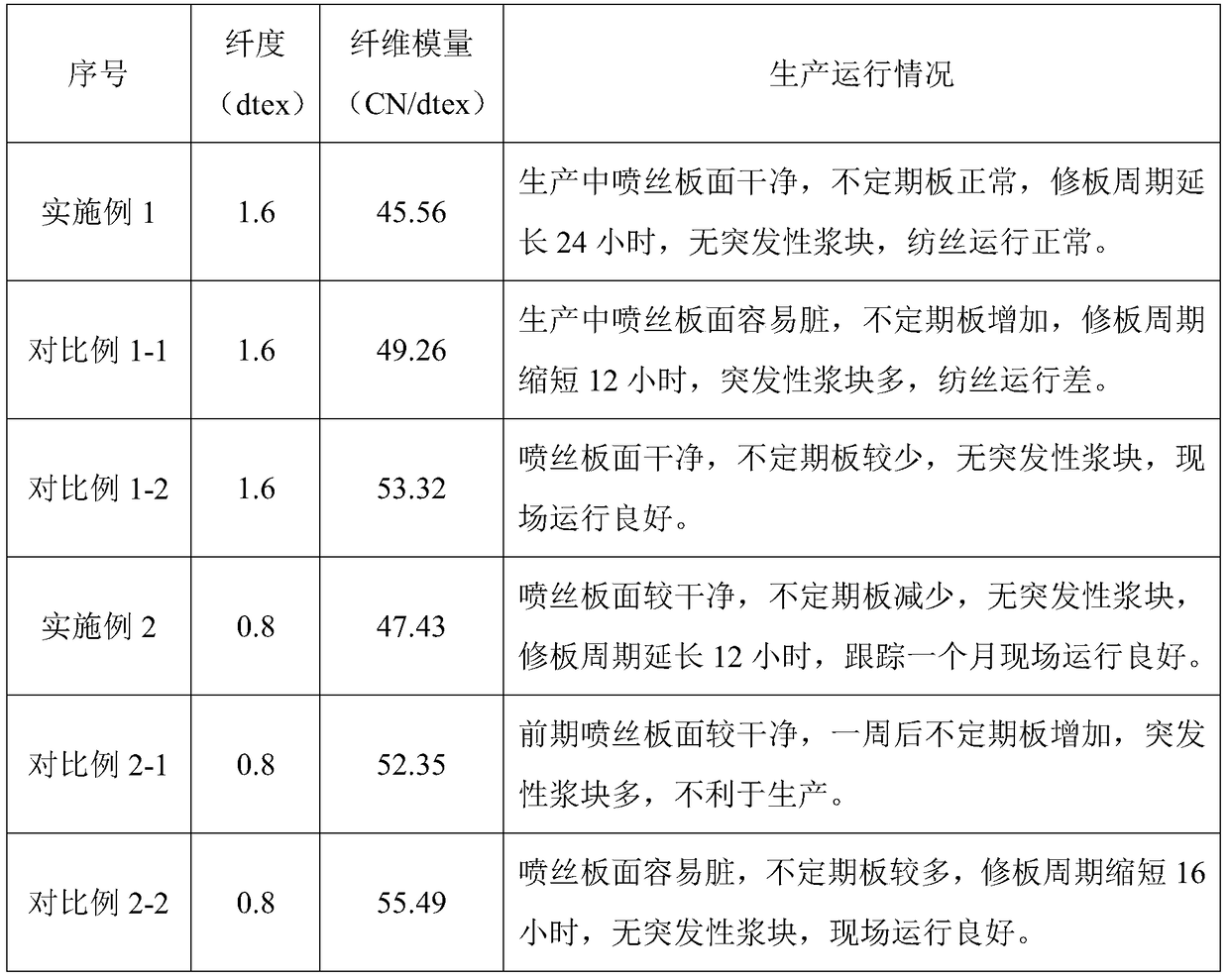

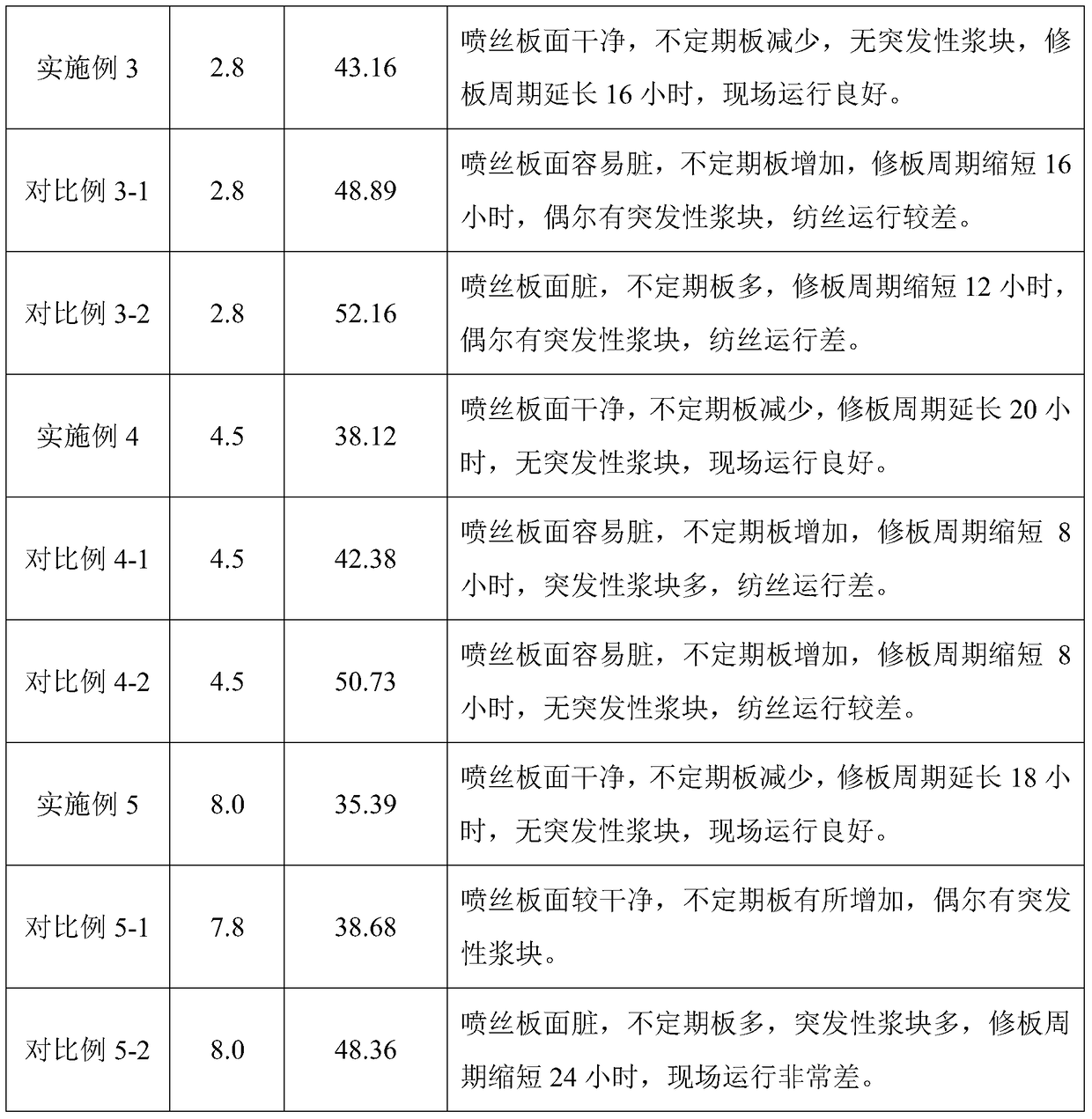

Examples

Embodiment 1

[0012] Example 1: The polyester melt synthesized with a titanium-based catalyst passes through the polyester and spinning handover point, enters the melt pipeline of the spinning device at a pressure of 6 MPa, and the melt enters the spinning box after being pressurized and filtered at 15 MPa Spinning at 8 MPa, spinning temperature 284°C, spinning speed 1122m / min, ring blowing cooling wind speed 1.0m / s, to obtain primary fibers; primary drafting of primary fibers at 60°C, drafting ratio 3.32 times, 170°C Secondary drafting, the drafting ratio is 1.25 times, 160°C tense heat setting for 30s, then crimping, cutting, and packaging to obtain 1.6dtex environmentally friendly polyester staple fibers.

Embodiment 2

[0016] Example 2: The polyester melt synthesized with a titanium-based catalyst passes through the polyester and spinning handover point, enters the melt pipeline of the spinning device at a pressure of 5 MPa, and the melt enters the spinning box after being pressurized and filtered at 18 MPa Spinning at 6MPa, spinning temperature 290°C, spinning speed 1400m / min, ring blowing wind speed 0.8m / s, to obtain primary fibers; primary drafting of primary fibers at 50°C, drafting ratio 3.00 times, 120°C Secondary drafting, the drafting ratio is 1.56 times, 170°C tense heat setting for 20s, then crimping, cutting, and packaging to obtain 0.8dtex environmentally friendly polyester staple fibers.

Embodiment 3

[0020] Example 3: The polyester melt synthesized with a titanium-based catalyst passes through the polyester and spinning handover point, enters the melt pipeline of the spinning device at a pressure of 3 MPa, and the melt enters the spinning box after being pressurized and filtered at 20 MPa 3MPa spinning, spinning temperature 280°C, spinning speed 1020m / min, ring blowing cooling wind speed 1.2m / s, to obtain primary fibers; primary drafting of primary fibers at 70°C, drafting ratio 3.96 times, 190°C Secondary drafting, the drafting ratio is 1.98 times, 180°C tense heat setting for 15s, then crimping, cutting, and packaging to obtain 2.8dtex environmentally friendly polyester staple fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com