Polyphenylene sulfide composite non-woven fabric as well as preparation method and application thereof

A polyphenylene sulfide, non-woven technology, applied in melt spinning, textile and papermaking, conjugated synthetic polymer rayon, etc. Good wettability, simple and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

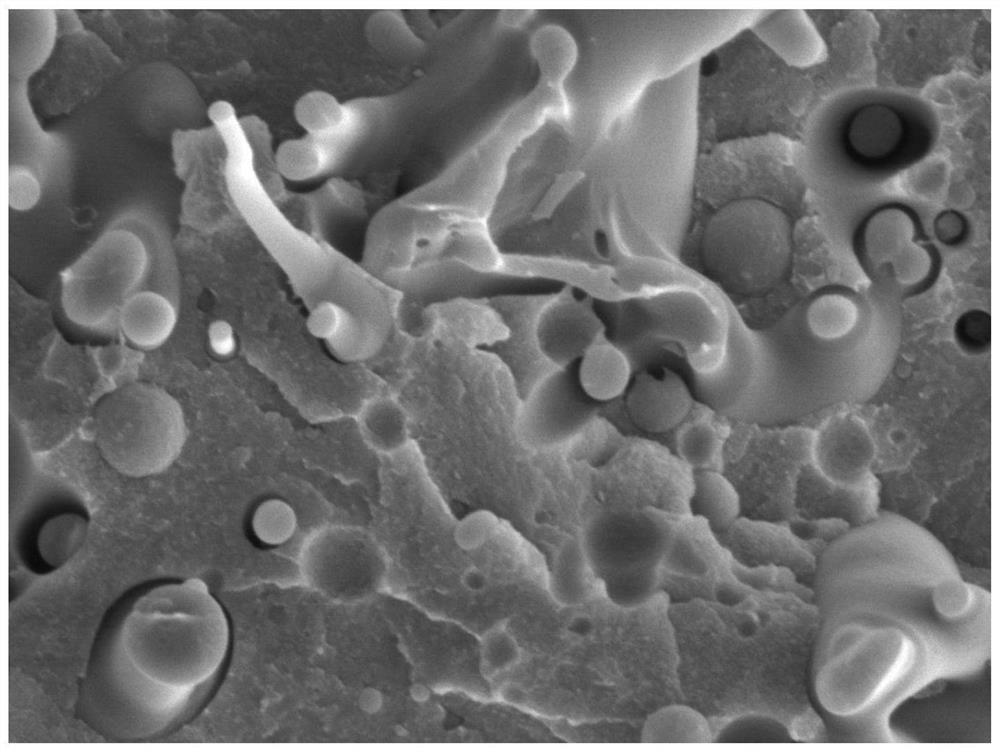

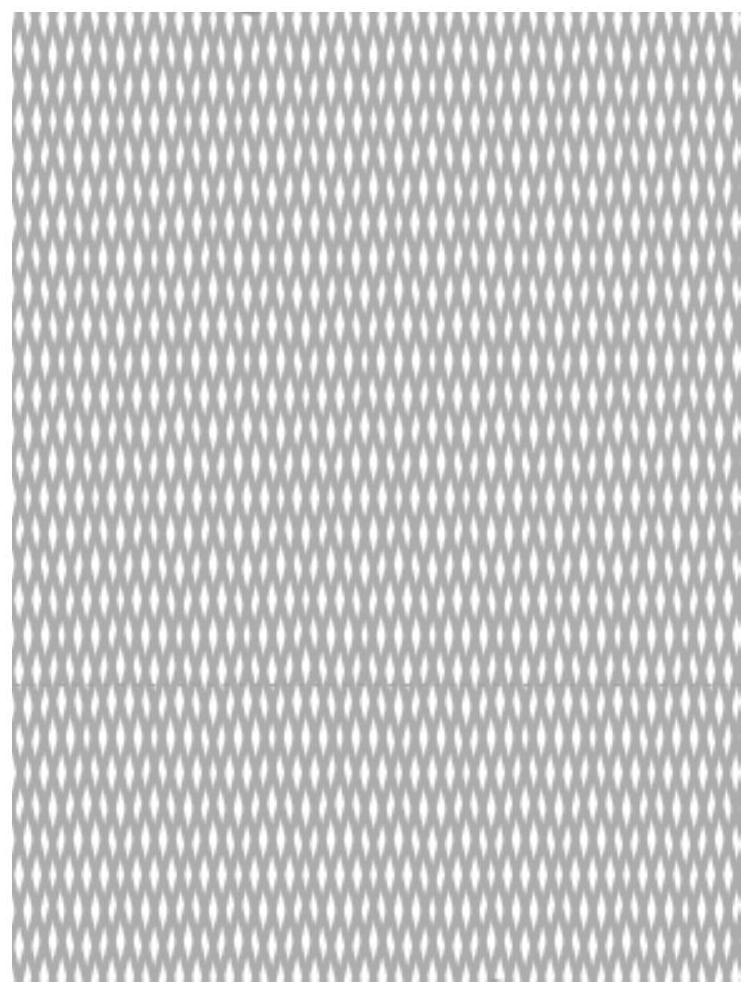

Image

Examples

Embodiment 1

[0034] This embodiment provides a preparation method of polyphenylene sulfide composite non-woven fabric, the steps are as follows:

[0035] (1) According to the following components and ingredients: 60% of polyphenylene sulfide, 30% of dried polyether sulfone, and 10% of dried E51 epoxy resin. The drying condition of the polyethersulfone is: drying at 120-140° C. for 4-6 hours; the drying condition of the epoxy resin is: drying at 60-80° C. for 1-2 hours.

[0036] (2) The ingredients in step (1) are uniformly mixed by a high-speed mixing mixer; the speed of the high-speed mixing mixer is 10000r / min.

[0037] (3) Extrude the above-mentioned high-speed mixed mixture through twin-screws. The temperature of each zone of the twin-screws is 120°C in the feed section, 285°C in the compression section, 290°C in the melting section, and 295°C in the metering section. Melt spinning was then performed through a spin pack with a melt spinning temperature of 300°C.

[0038] (4) After th...

Embodiment 2

[0050] This embodiment provides a preparation method of polyphenylene sulfide composite non-woven fabric, the steps are as follows:

[0051] (1) According to the following components and ingredients: 60% of polyphenylene sulfide, 25% of dried polyethersulfone, and 15% of dried E20 epoxy resin. The drying condition of the polyethersulfone is: drying at 120-140° C. for 4-6 hours; the drying condition of the epoxy resin is: drying at 60-80° C. for 1-2 hours.

[0052] (2) The ingredients in step (1) are uniformly mixed by a high-speed mixing mixer; the speed of the high-speed mixing mixer is 12500r / min.

[0053] (3) The above-mentioned high-speed mixed mixture is extruded through twin-screws. The temperature of each zone of the twin-screws is 100°C in the feed section, 275°C in the compression section, 280°C in the melting section, and 285°C in the metering section. Melt spinning was then performed through a spin pack with a melt spinning temperature of 290°C.

[0054] (4) After...

Embodiment 3

[0066] This embodiment provides a preparation method of polyphenylene sulfide composite non-woven fabric, the steps are as follows:

[0067] (1) According to the following components and ingredients: 70% of polyphenylene sulfide, 10% of dried polyethersulfone, and 20% of dried E44 epoxy resin. The drying condition of the polyethersulfone is: drying at 120-140° C. for 4-6 hours; the drying condition of the epoxy resin is: drying at 60-80° C. for 1-2 hours.

[0068] (2) The ingredients in step (1) are uniformly mixed by a high-speed mixing mixer; the speed of the high-speed mixing mixer is 11000r / min.

[0069] (3) The above-mentioned high-speed mixed mixture is extruded through twin-screws. The temperature of each zone of the twin-screws is 100°C in the feed section, 260°C in the compression section, 265°C in the melting section, and 270°C in the metering section. Melt spinning was then carried out through a spin pack with a melt spinning temperature of 275°C.

[0070] (4) Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com