Hollow fiber film and method for producing the same

A manufacturing method and technology of fiber membranes, applied in the field of preparation of hollow fiber membranes, can solve problems such as unsatisfactory shape recovery, difficulty in forming holes in fiber membranes, and high energy consumption, etc., and achieve easy operation, good product quality, and membrane-making technically simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The fiber-grade polyether polyurethane with a mass ratio of hard segment / soft segment of 1 / 2 is used as the polymer matrix phase, and the mass percentage is 25%; the composite porogen is 0.01 μm SiO 2 The mixture of powder and PVP accounts for 60% of the total mass of the system, of which the former is an interface pore-forming agent, accounting for 30% of the total mass of the composite porogen, and the latter is a non-interface pore-forming agent, accounting for 30% of the total mass of the composite porogen. 70% of the total mass; DMSO is selected as the organic low-molecular liquid, and the mass percentage is 15%. The mixture of the above three is used as a film-forming system, which is heated and forced to pre-mix in a mixing tank at a heating temperature of 130 ° C. After dissolution and melting After waiting for the process, it is fed into the twin-screw extruder, and the hollow spinneret is used for melt blending and spinning to form a film. The draw ratio of the...

Embodiment 2

[0034] The proportioning of the interface hole porogen in Example 1 is adjusted to 10% of the total mass of the porogen, the proportioning of the non-interface hole porogen is adjusted to 90% of the total mass of the porogen, and the spinneret draw ratio Option 3, other conditions remain unchanged, to obtain the hollow membrane.

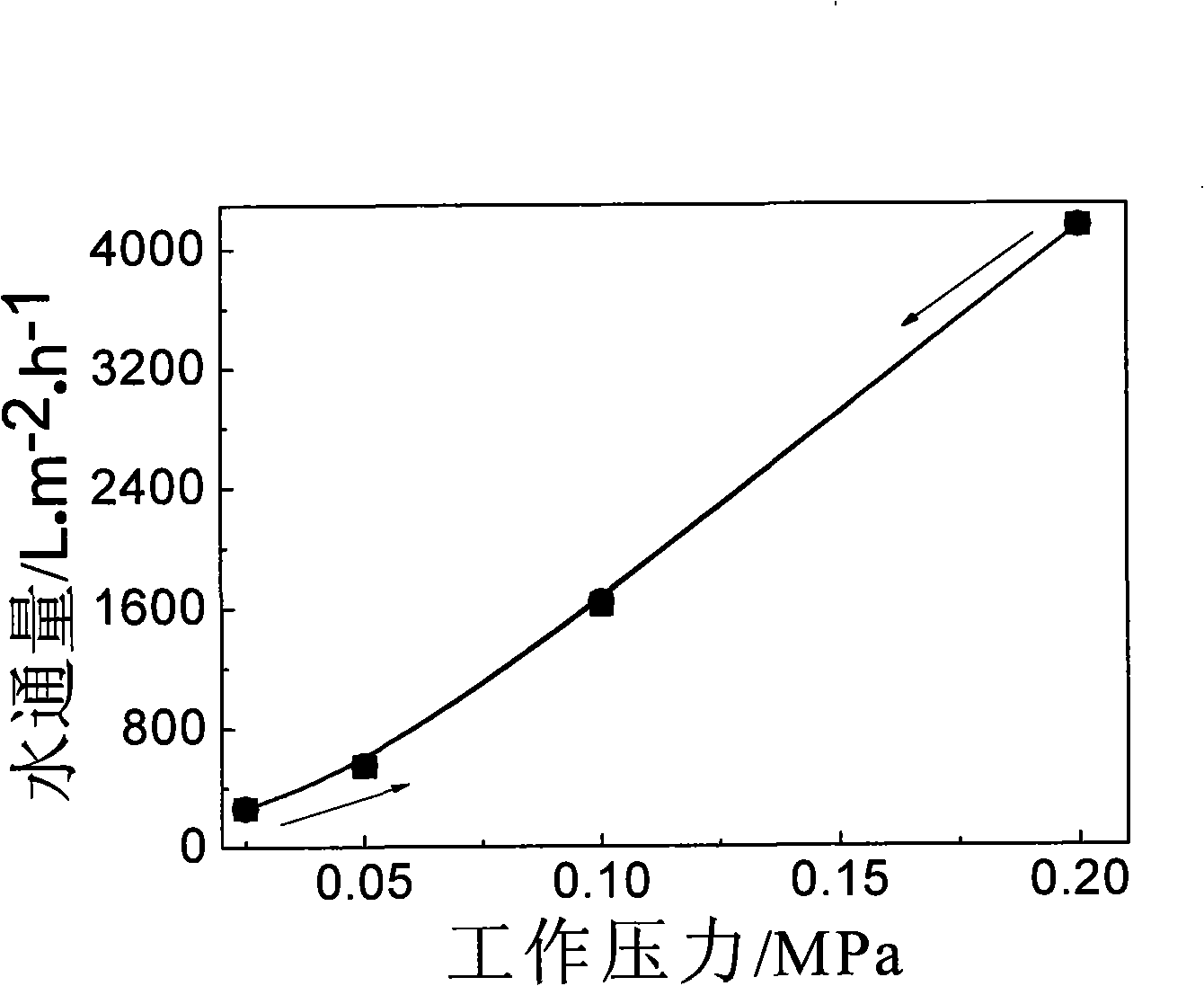

[0035] After inspection, the hollow membrane obtained in this example was measured at 0.1MPa and at a temperature of 25°C, and the water flux was measured by the internal pressure method, and the corresponding value obtained was: 1090 (L·m -2 h -1 ).

Embodiment 3

[0037] The fiber-grade polyether polyurethane with a mass ratio of hard segment / soft segment of 1 / 2 is used as the polymer matrix phase, and the mass percentage is 45%; the composite porogen is 0.01 μm SiO 2 Powder, 5μm CaCO 3 The mixture of powder and PEG accounts for 60% of the total mass of the system, of which the former two are interfacial porogens with a mass ratio of 1 / 1, accounting for 30% of the total mass of the composite porogen, and the latter is a non- The interface pore porogen accounts for 70% of the total mass of the composite porogen; the organic low-molecular liquid is DMSO, and the mass percentage is 20%. The mixture of the above three is used as a film-forming system, which is heated and forced to pre- After mixing, dissolving and melting, it is fed into the twin-screw extruder, and the hollow spinneret is used for melt blending and spinning to form a film. The draw ratio of the spinneret is selected as 3, and the processing temperature is controlled at 155...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com