Low-melting-point polyester and preparation method thereof

A low-melting polyester and low-melting technology, applied in the field of polyester materials, to achieve the effects of simple formula, enhanced fluidity, and increased spinning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

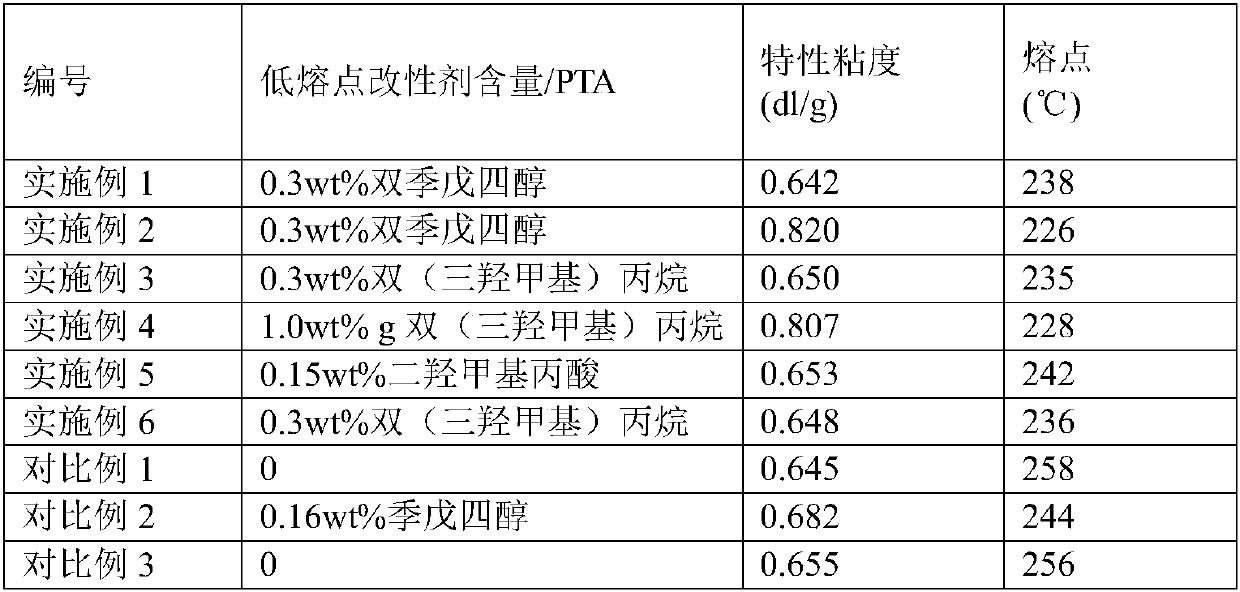

Examples

preparation example Construction

[0036] A preparation method for low melting point polyester, comprising the following steps:

[0037] 1) Esterification reaction: Add terephthalic acid, ethylene glycol, low melting point modifier and catalyst together into a polymerization reactor preheated at 50-100°C, stir for 10-30min to mix evenly; add under the protection of inert gas Press and heat up, and carry out esterification reaction at 220-260°C and a pressure of 0-0.35MPa until the water effluent ends.

[0038] 2) Polycondensation reaction: evacuate for 30-90 minutes to an absolute pressure below 1000 Pa, and at the same time raise the temperature for pre-condensation reaction. The pre-condensation temperature is 260-280°C. Then carry out the final polycondensation reaction at 265-285° C. and 0-300 Pa for 10-120 minutes, discharge and pelletize after the reaction to obtain low-melting point polyester.

Embodiment 1

[0040] Add 664g of terephthalic acid, 310g of ethylene glycol, 2.0g of dipentaerythritol, and 0.3g of ethylene glycol antimony into a 2L reaction kettle, stir at 50-100°C for 15min, and then pass in N 2 , The esterification reaction starts at 230°C and 0.3MPa. After the water outlet is finished, a low vacuum is drawn, and the kettle temperature is set to 280° C. at the same time. After the vacuum instrument reaches -101kPa, the high vacuum is pumped, and the current reading is recorded after the vacuum degree reaches below 100Pa. It takes 45 minutes from the current rise to the current corresponding to the fiber-grade polyester sample. Stop the reaction, discharge and pelletize.

Embodiment 2

[0042] Add 664g of terephthalic acid, 310g of ethylene glycol, 2.0g of dipentaerythritol, and 0.3g of ethylene glycol antimony into a 2L reaction kettle, stir at 50-100°C for 15min, and then pass in N 2 , The esterification reaction starts at 233°C and 0.28MPa. After the water outlet is finished, a low vacuum is drawn, and the kettle temperature is set to 280° C. at the same time. After the vacuum gauge reaches -101kPa, draw a high vacuum, record the current reading after the vacuum degree reaches below 100Pa, and react for 90 minutes from the current rising. Stop the reaction, discharge and pelletize.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com