Production process of steel wire rod for producing prestress steel strand by utilizing mini-rolling mill

A technology of prestressed steel strands and mini rolling mills, which is applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of long aging time and unstable performance of finished products, and achieve shortening of aging time and reduction of fans The effect of using amount and lowering the spinning temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

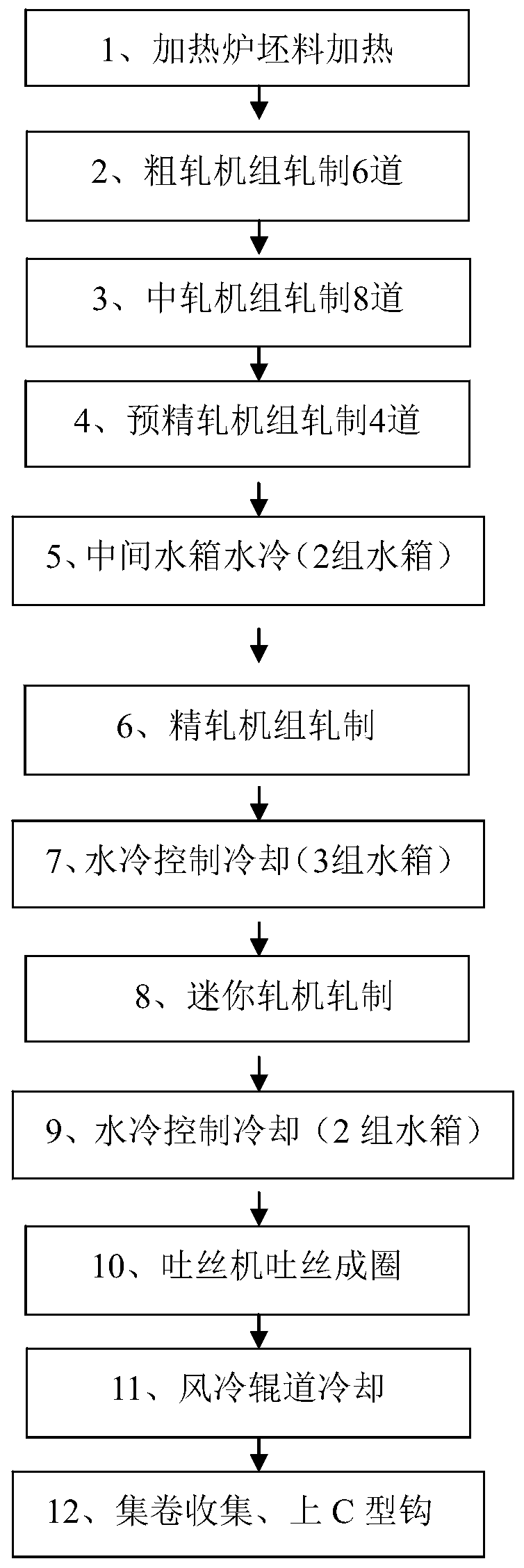

[0013] See figure 1 , a method of utilizing a mini-rolling mill to produce wire rods for prestressed steel strands. The wire rods prepared in this embodiment are Φ12.5mm 82B wire rods, which include heating of the heating furnace blank, 6 passes of rolling by the roughing mill, There are 8 rolling passes in the intermediate rolling mill, 4 rolling passes in the pre-finishing rolling mill, water cooling, rolling in the finishing mill, water cooling, mini mill rolling, water cooling, silk spinning, air-cooled roller table cooling and coil collection processes.

[0014] In the billet heating process, the temperature in the heating section of the heating furnace is 1100-1180°C, the temperature in the soaking section is 1160-1240°C, and the rolling start temperature is controlled to 1080±30°C; in the rolling process of the finishing mill, the temperature at the entrance of the finishing mill is 880- 900°C; in the mini-mill rolling process, the inlet temperature of the mini-rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com