A kind of rubber composition and vulcanized rubber and preparation method thereof

A rubber composition and rubber technology, applied in transportation and packaging, rolling resistance optimization, special tires, etc., can solve problems such as large rolling resistance, permanent deformation, large heat generation, difficult high-performance green tires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

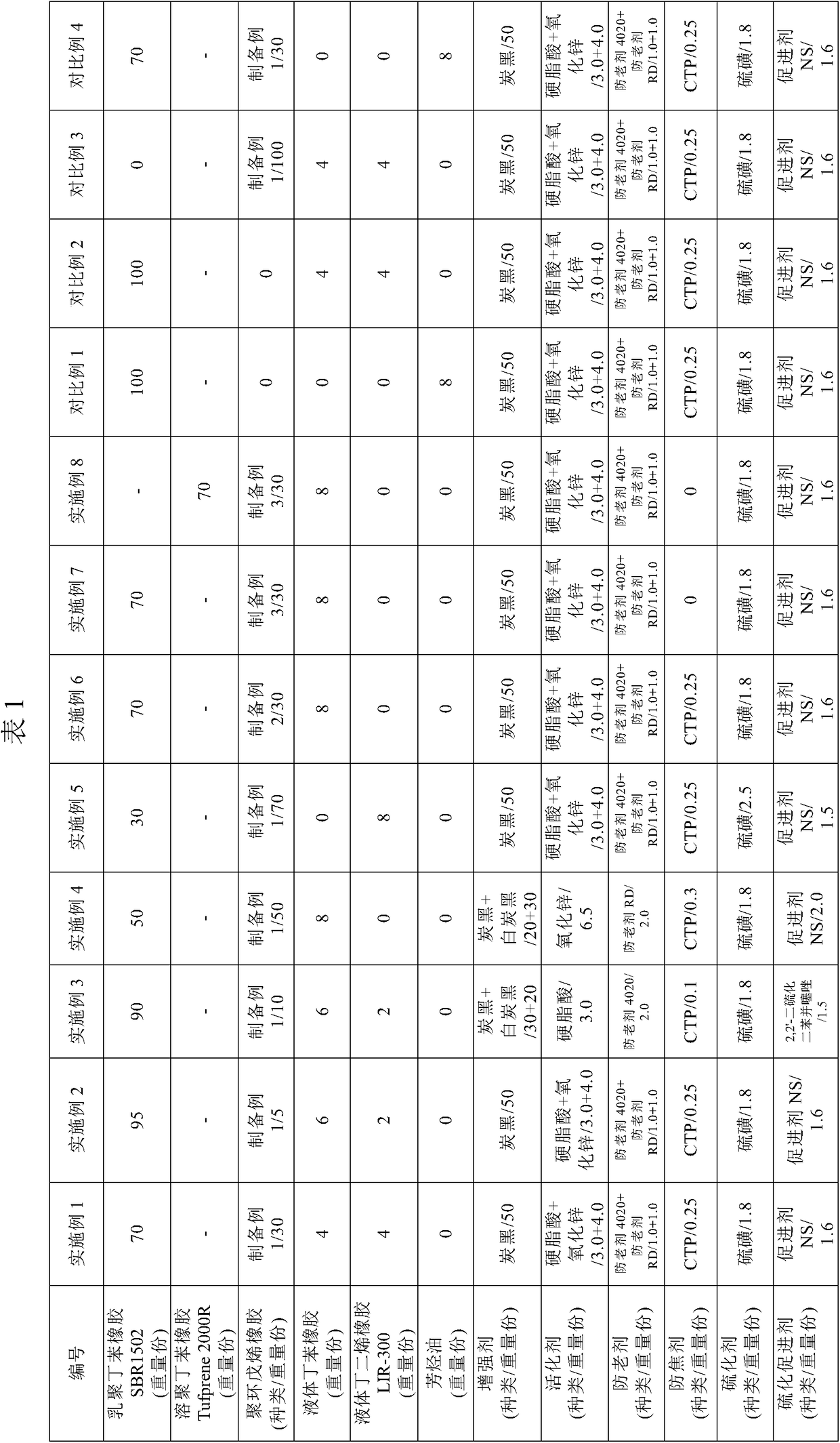

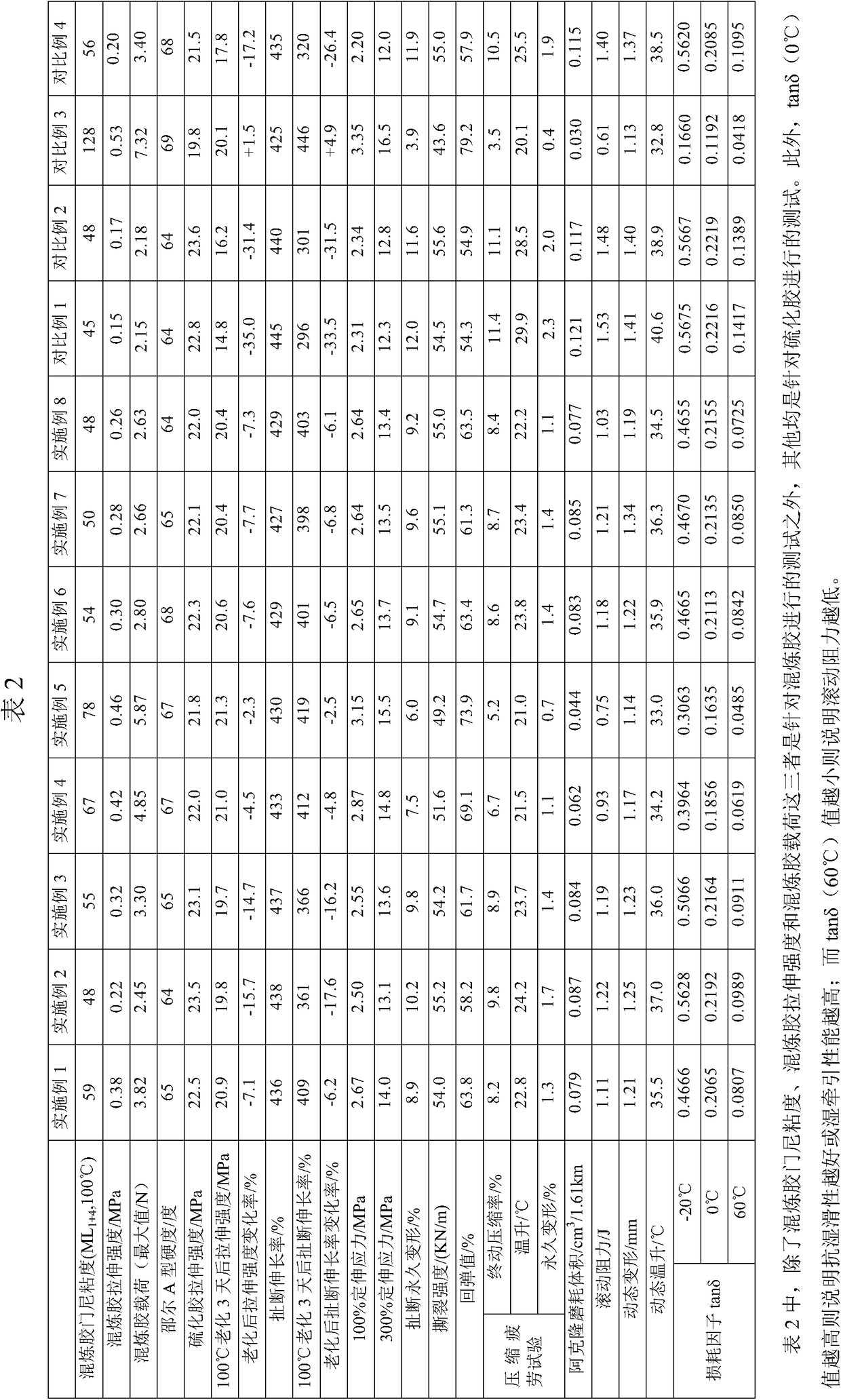

Examples

preparation example Construction

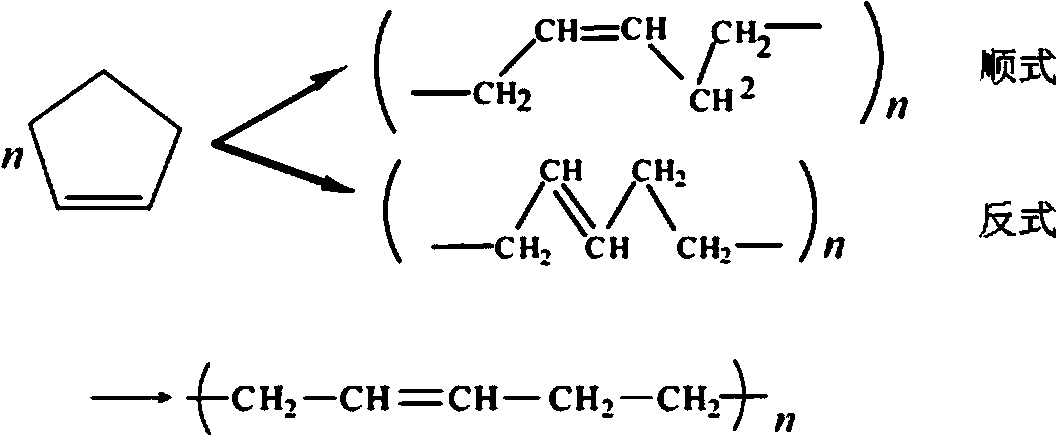

[0015] The polycyclopentene rubber can be prepared by ring-opening polymerization of cyclopentene. Specifically, when the polycyclopentene rubber is prepared by ring-opening polymerization, the preparation method includes: performing ring-opening polymerization of cyclopentene in a solvent in the presence of a ring-opening polymerization catalyst and a molecular weight regulator.

[0016] Wherein, the ring-opening polymerization catalyst can adopt various existing catalysts capable of ring-opening polymerization of cyclopentene, such as tungsten or molybdenum two-component or three-component catalysts, tantalum, niobium, rhenium catalysts, and At least one of the metal catalysts is preferably a catalytic system composed of tungsten-containing compounds and / or molybdenum-containing compounds, organoaluminum compounds and / or activators. Wherein, the tungsten-containing compound may be tungsten hexachloride, and the molybdenum-containing compound may be molybdenum tetrachloride. ...

preparation example 1

[0077] This preparation example is used to illustrate the polycyclopentene rubber provided by the present invention and its preparation method.

[0078] In a 2L reactor replaced with purified nitrogen, 200g of cyclopentene, 800g of n-hexane, 20.0mL of toluene solution containing 0.05mol / L trichlorophenol, 20.0mL of toluene solution containing 0.03mol / L WCl 6 33.3mL of toluene solution and 6.0mL of hexane solution containing 0.1mol / L 1-butene, stir evenly and keep the temperature of the reaction material at 0°C, then add toluene containing 0.3mol / L triisobutylaluminum under stirring Solution 13.3mL, filled with refined nitrogen to keep the reactor pressure at 0.2MPa (gauge pressure), constant temperature reaction for 3.0 hours, after the polymerization reaction ended, add 20mL concentration of 100g / L 2,6-di-tert-butyl- The 4-methylphenol ethanol solution terminated the reaction, and then the glue solution was released and coagulated with ethanol. The obtained polymer was dried ...

preparation example 2

[0080] This preparation example is used to illustrate the polycyclopentene rubber provided by the present invention and its preparation method.

[0081] Prepare polycyclopentene rubber according to the method of Preparation Example 1, the difference is that 20.0 mL of toluene solution containing 0.05 mol / L trichlorophenol is replaced with 16.0 mL of 0.05 mol / L tetrachlorophenol toluene solution, and 0.1 mol / L The amount of hexane solution of L 1-butene is 7.2mL, the amount of toluene solution containing 0.3mol / L triisobutylaluminum is 11.6mL, the polymerization reaction temperature is -5°C, and the reactor pressure is 0.5MPa (gauge pressure), the polymerization reaction time was 3.0 hours, and 160.2 g of polycyclopentene rubber was obtained. After detection, the content of the trans structure in the polycyclopentene was 84.6% by weight, the number average molecular weight of the polymer was 178500, the molecular weight distribution was 1.87, and the Mooney viscosity was 50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com