Production method of high-volage coil of voltage mutual inductor

A technology of voltage transformers and high-voltage coils, applied in the direction of inductors, transformers/inductor coils/windings/connections, coil manufacturing, etc. Ensure the stability and reliability of mechanical and electrical insulation performance, reasonable coil insulation structure, and uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

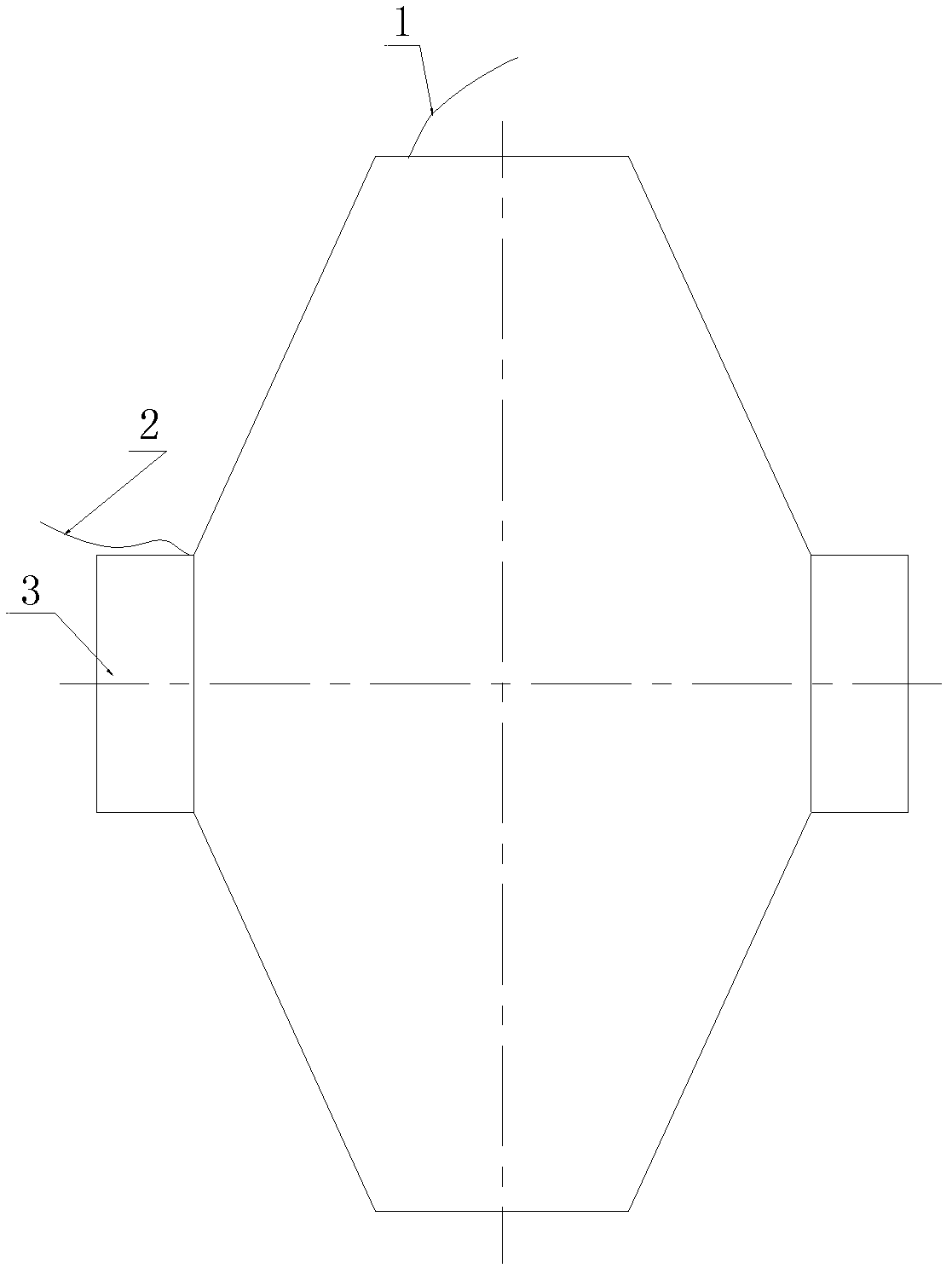

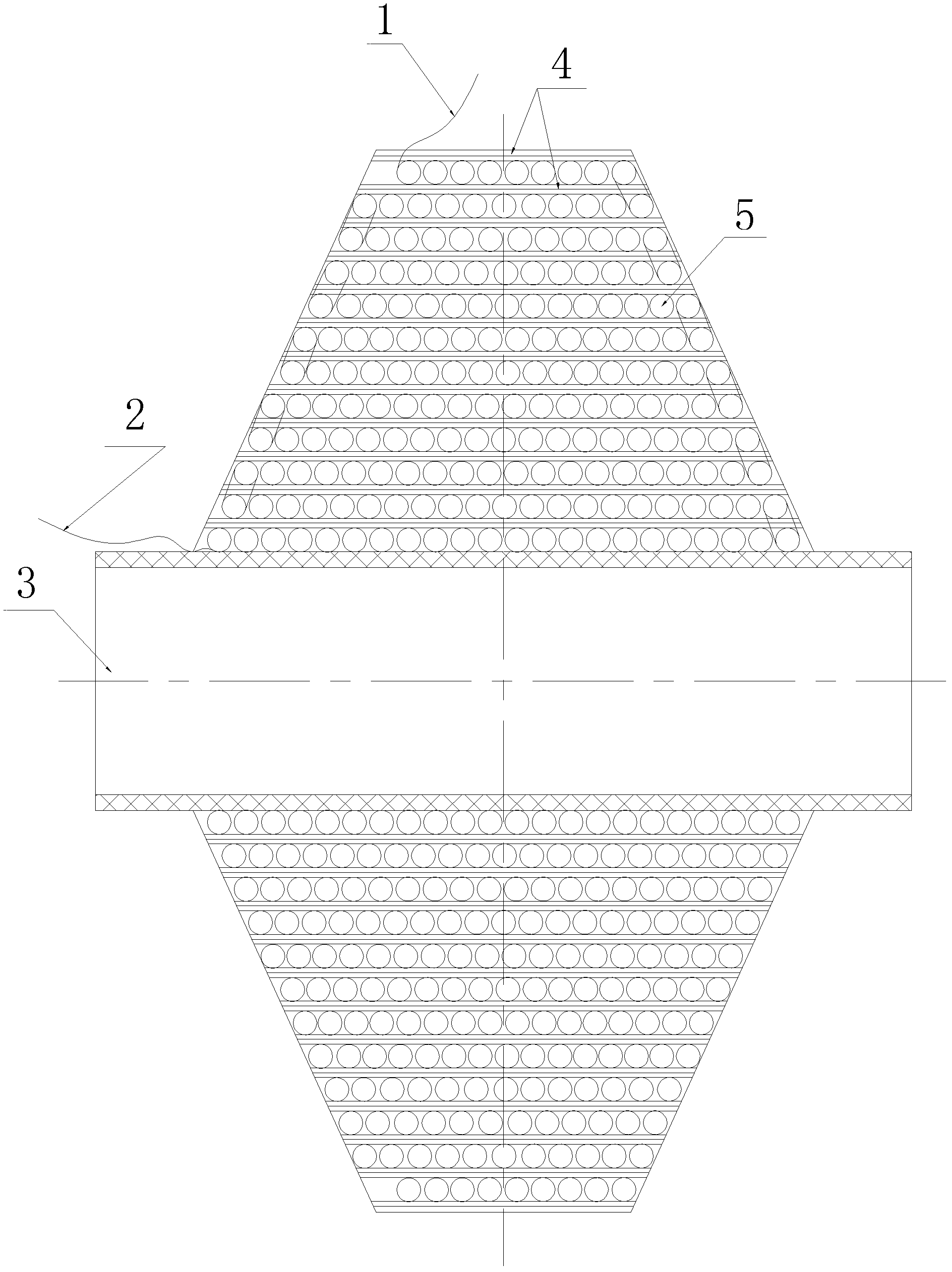

[0034] The preparation method of the voltage transformer high-voltage coil of the present invention, according to the following steps:

[0035] (1) Winding on the outer surface of skeleton 3 with film 5 earlier;

[0036] (2) Fix the enameled wire 4 on the film 5 with electrical tape.

[0037] (3) Set aside a sufficient length of enameled wire 4 for the lead wire 2 at the low-voltage end of the coil;

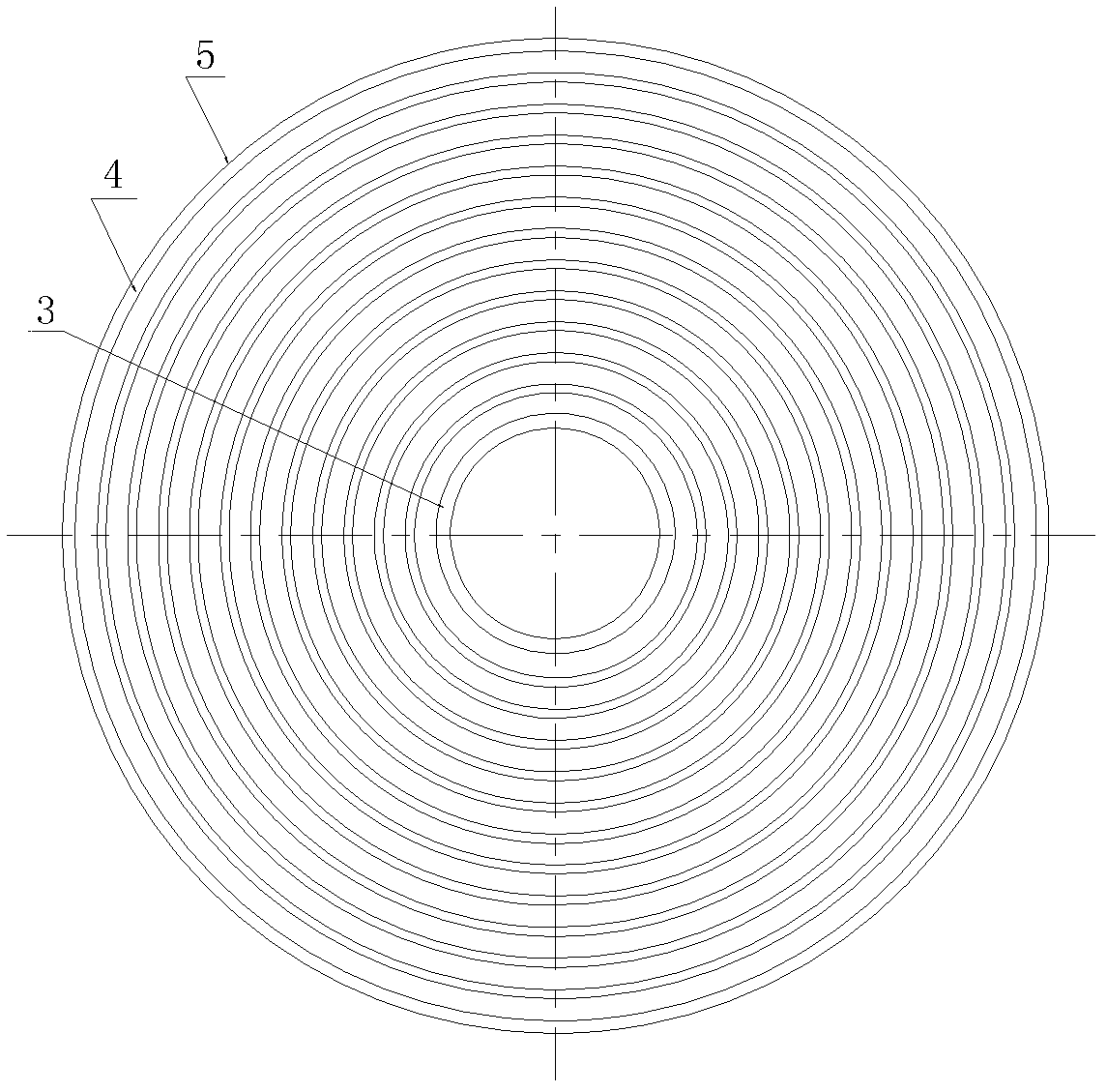

[0038] (4) Use the enameled wire 4 to uniformly wind the coil along the axial direction of the skeleton 3, and wrap the film 5 between every two layers of enameled wire.

[0039] (5) After the enameled wire 4 has reached the prescribed number of turns, the film 5 is wrapped around it.

[0040] (6) Lead out the end of the enameled wire 4 as the lead wire 1 at the high voltage end.

[0041] (7) Put the wound coil into an oven for drying and curing.

[0042] In the step (1), the number of winding layers of the film 5 is 3 layers.

[0043] In the step (2), the distance between t...

Embodiment 1

[0049]Embodiment 1: first use film 5 to wind 3 layers on the outer surface of skeleton 3, wire 4 is fixed on film 5 with electrical tape at 30 mm from the end of film 5, and the lead-out length of 200 mm is used as low-voltage end lead-out line 2; Wrinkles and bulges occur when the coil is wound, and the wires 4 are wound in a uniform arrangement along the coil axis in an "S" shape, that is, each layer of wires can only proceed to the next layer after winding the specified number of turns. Winding, 2 to 6 layers of film 5 are wrapped between each 2 layers of wires to meet the requirements for interlayer insulation; in the prior art, each layer is wound with half the number of turns of wire, two layers of film are wound, and then the other half of the turn is wound number of wires, and then wind two layers of film, so that the coils in the middle are easy to bulge, loosen, and the film and wires move; each layer of wires in the present invention can only be rolled to the next la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com