A kind of silicone rubber and its preparation method and application

A silicone rubber and silane-based technology, which is applied in the field of silicone rubber and its preparation, can solve the problems of high strength, high temperature, low thermal weight loss, performance that cannot meet the requirements, and physical property decline, and achieve low thermal weight loss, excellent mechanical properties, and fast curing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

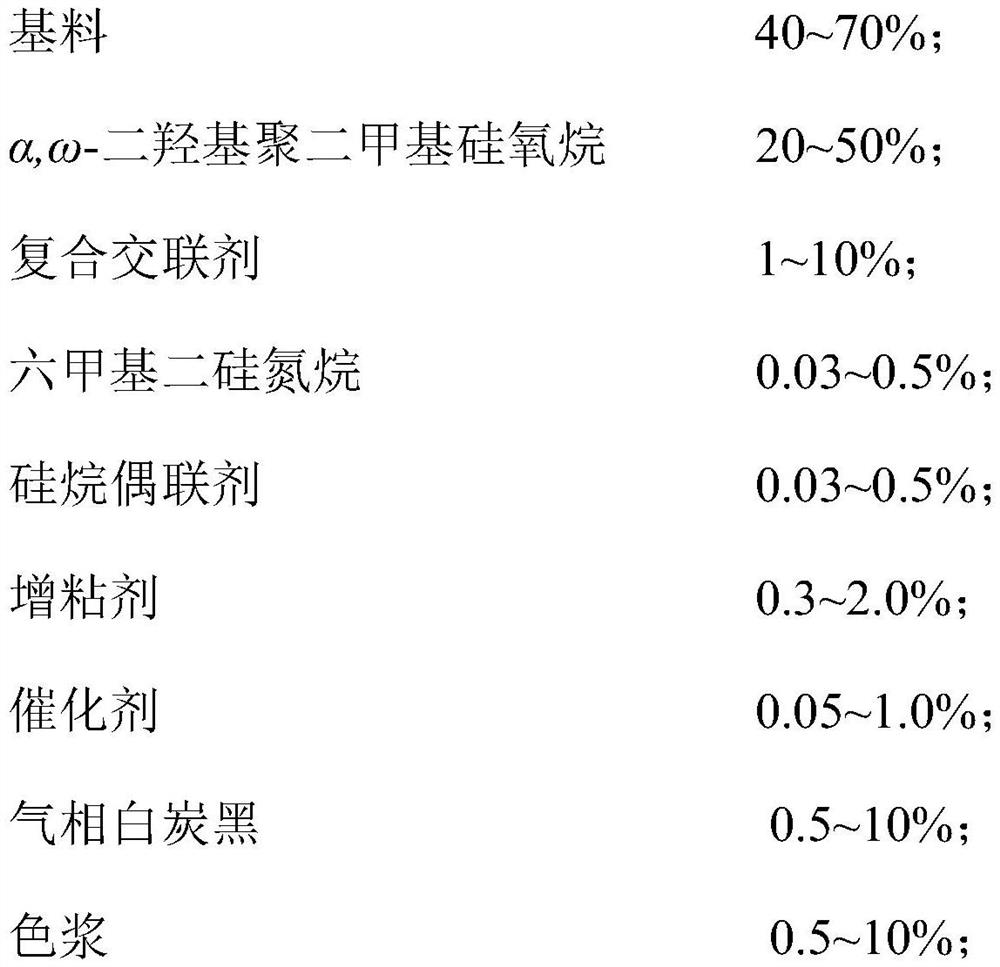

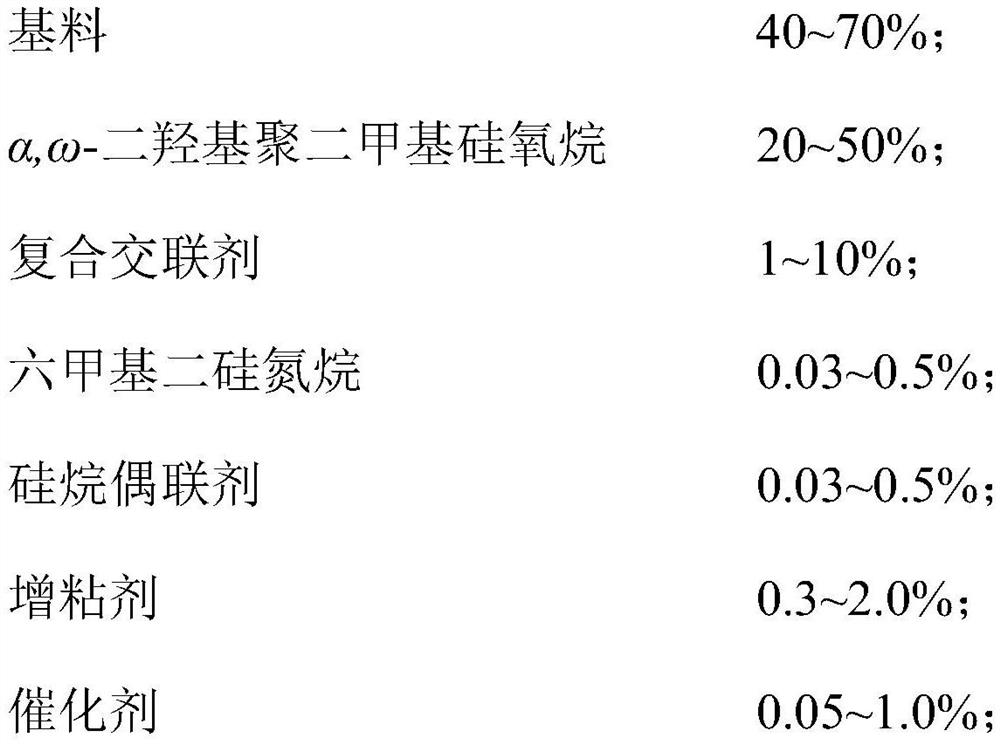

[0065] This embodiment provides a kind of silicone rubber, the preparation raw material of described silicone rubber comprises the following components by weight percentage: base material 55%, α, ω-dihydroxypolydimethylsiloxane (viscosity is 20000cps) 30%, methyl tributyl ketoxime silane 4%, vinyl tributyl ketoxime silane 1%, hexamethyldisilazane 0.2%, (3-methacryloyloxypropyl) trimethoxysilane 0.2%, γ-aminopropyltriethoxysilane 1%, dibutyltin dilaurate 0.2%, red iron oxide color paste 2% and fumed silica (particle size 50nm) 6.4%.

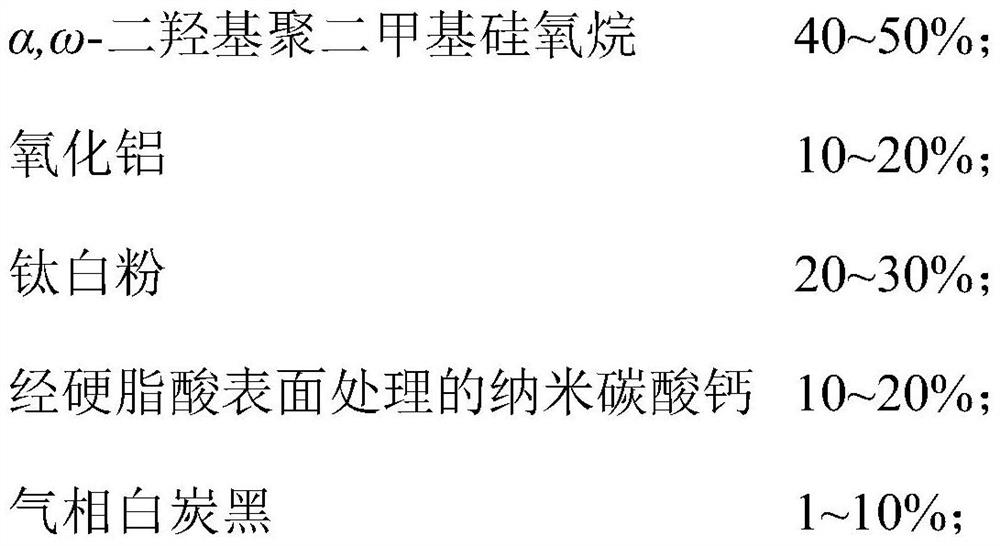

[0066] The raw materials for the preparation of the above-mentioned base material include the following components by weight percentage: α, ω-dihydroxy polydimethylsiloxane (viscosity is 20000cps) 45%, untreated alumina (particle size is 30 μm) 15% %, titanium dioxide (particle diameter is 50nm) 22%, nano calcium carbonate (particle diameter is 100nm) 15% and fumed white carbon black (particle diameter is 50nm) 3% through stearic acid surface trea...

Embodiment 2

[0071] This embodiment provides a kind of silicone rubber, the preparation raw material of described silicone rubber comprises the following components by weight percentage: base material 40%, α, ω-dihydroxypolydimethylsiloxane (viscosity is 10000cps) 50%, methyl tributyl ketoxime silane 1%, vinyl tributyl ketoxime silane 1.5%, hexamethyldisilazane 0.5%, (3-glycidoxypropyl) trimethoxysilane 0.5 %, γ-aminopropyltrimethoxysilane 2%, dibutyltin dilaurate 1%, red iron oxide color paste 1%, and fumed white carbon black (particle size 80nm) 2.5%.

[0072] The raw materials for the preparation of the above-mentioned base material include the following components by weight percentage: α, ω-dihydroxy polydimethylsiloxane (viscosity is 10000cps) 40%, untreated alumina (particle size is 40 μm) 20% %, titanium dioxide (particle size is 40nm) 20%, nano calcium carbonate (particle size is 100nm) 10% and fumed white carbon black (particle size is 80nm) 10% through stearic acid surface treatm...

Embodiment 3

[0077] This embodiment provides a kind of silicone rubber, the preparation raw material of described silicone rubber comprises the following components by weight percentage: base material 60%, α, ω-dihydroxypolydimethylsiloxane (viscosity is 30000cps) 20%, methyl tributyl ketoxime silane 7%, vinyl tributyl ketoxime silane 0.3%, hexamethyldisilazane 0.1%, (3-glycidoxypropyl) trimethoxysilane 0.2 %, 0.3% of γ-aminopropyltrimethoxysilane, 0.1% of dibutyltin dilaurate, 2% of red iron oxide color paste and 10% of fumed white carbon black (particle size: 20nm).

[0078] The raw materials for the preparation of the above-mentioned base material include the following components by weight percentage: α, ω-dihydroxy polydimethylsiloxane (viscosity is 30000cps) 49%, untreated alumina (particle size is 30 μm) 10% %, titanium dioxide (particle size is 40nm) 20%, nano calcium carbonate (particle size is 100nm) 20% and fumed white carbon black (particle size is 80nm) 1% through stearic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com