Sea-island polyphenylene sulfide superfine fiber and preparation method thereof

A technology of polyphenylene sulfide and ultrafine fiber, which is applied in the field of fiber manufacturing, can solve the problems of fiber size (diameter, uncontrollable length, high toxicity of organic solvents, poor mechanical properties, etc.), so as to improve spinnability and reduce spinning The effect of silk temperature and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

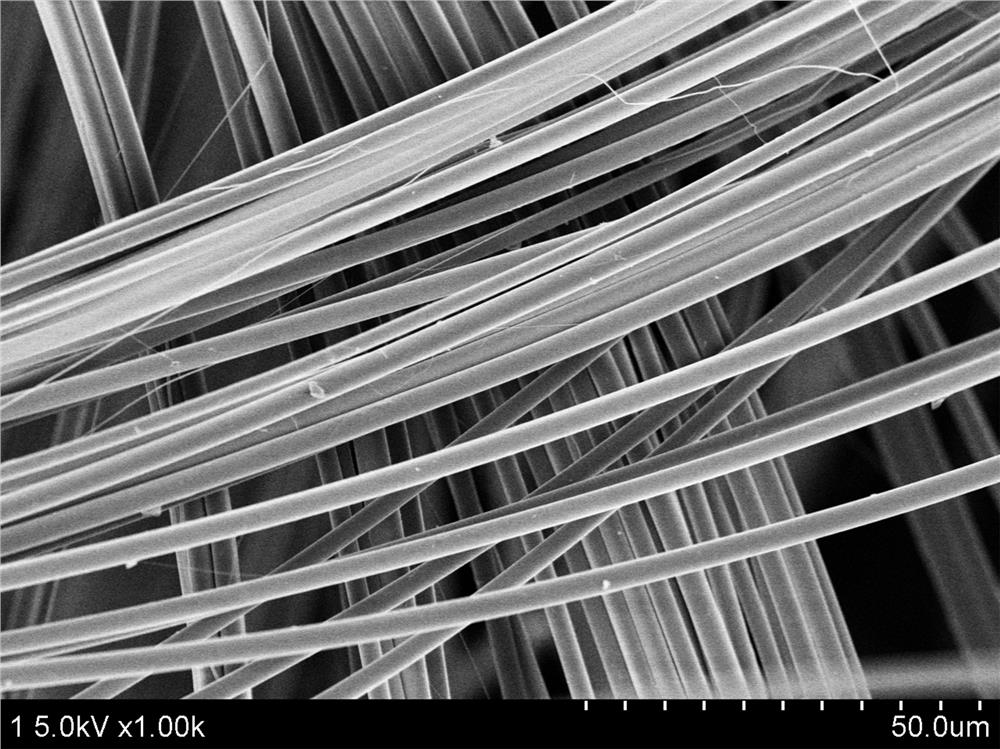

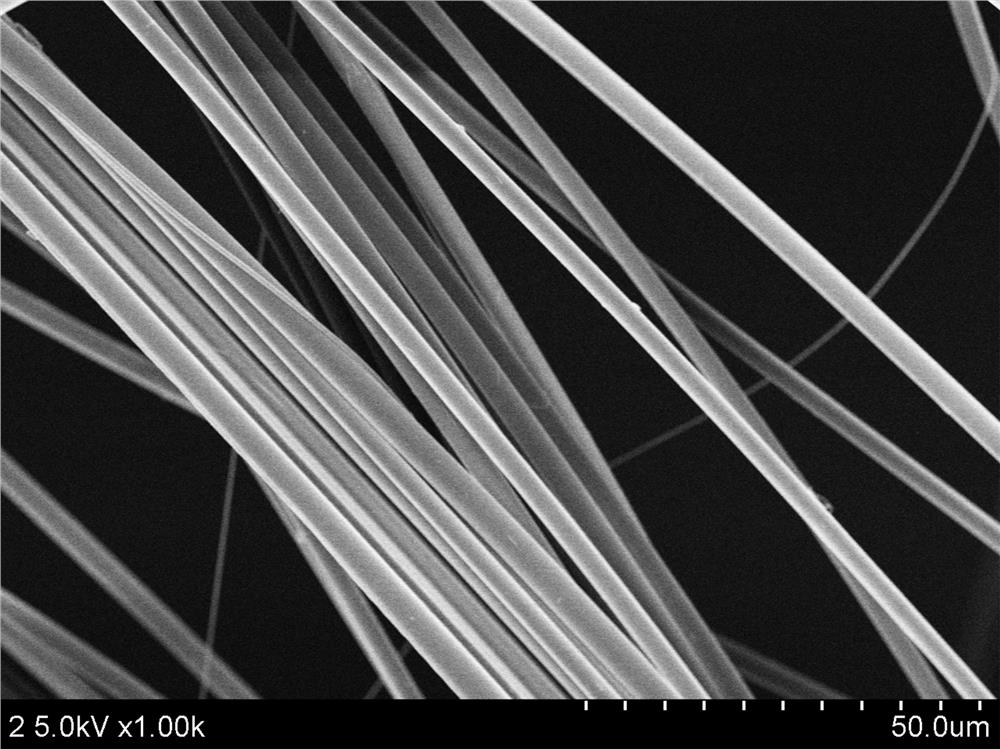

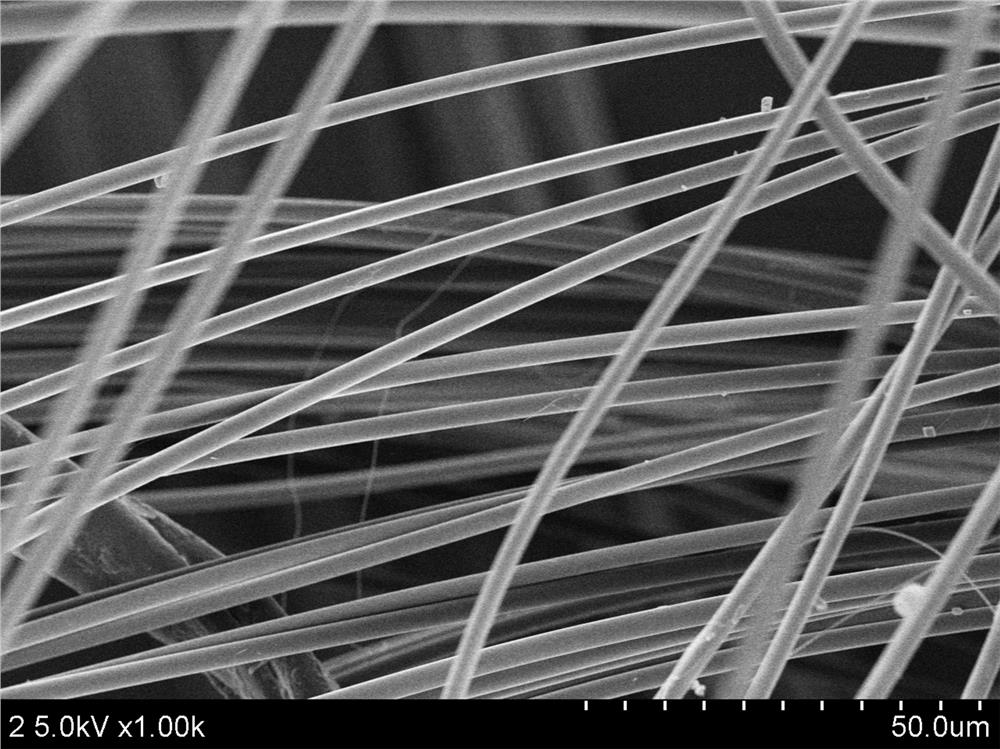

Image

Examples

Embodiment 1-6

[0028] The present invention will be further described below in conjunction with the examples. The present invention uses three kinds of polyphenylene sulfides. In order to show the difference, they are represented by polyphenylene sulfide A, polyphenylene sulfide B and polyphenylene sulfide C respectively, "A" , "B" and "C" have no actual technical meaning, and those skilled in the art should understand that the present invention is not limited to the following examples, and any improvements and equivalent changes made on the basis of the specific examples of the present invention are within Within the scope of the claims of the present invention. The preparation method of embodiment 1-6 sea-island type polyphenylene sulfide superfine fiber

[0029] Examples 1-6 are respectively a preparation method of sea-island polyphenylene sulfide ultrafine fibers, and the process parameters in the preparation process are shown in Table 1. The specific preparation process includes the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com