Nylon-6 resin, nylon-6 fiber and preparation method thereof

A nylon and resin technology, applied in the field of spinning materials, to achieve the effects of reduced impact, good dispersion and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]

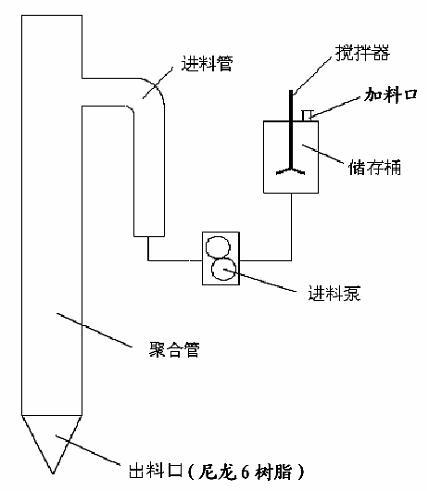

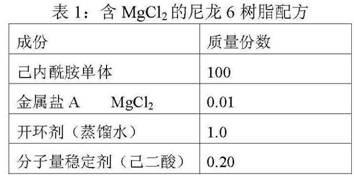

[0046] Such as figure 1 Shown: Stir and mix the above materials in the storage tank evenly, and continuously send the above materials into the straight VK pipe through the feed pump, and the materials are polymerized by the ring-opening agent. The temperature control in the polymerization reaction is divided into three parts In the first stage, the material is in the upper section of the straight VK tube, and the temperature is controlled between 230-260°C; the middle section of the straight VK tube, the temperature is controlled between 240-260°C; the temperature in the lower section of the straight VK tube is controlled at 220-240°C In between, the polymer melt flows down to the bottom of the VK tube through layers of baffles, and is taken out by the discharge pump to maintain the liquid level in the tube. The polymerization time is 10 hours. The obtained polymer melt is washed with water, cut into pellets, and dried in vacuum to remove moisture and small molecul...

Embodiment 2

[0050]

[0051] Such as figure 1 Shown: Stir and mix the above materials in the storage tank evenly, and continuously send the above materials into the straight VK pipe through the feed pump, and the materials are polymerized by the ring-opening agent. The temperature control in the polymerization reaction is divided into three parts In the first stage, the material is in the upper section of the straight VK tube, and the temperature is controlled between 230 and 275°C; in the middle section of the straight VK tube, the temperature is controlled between 240 and 265°C; in the lower section of the straight VK tube, the temperature is controlled between 220 and 245°C In between, the polymer melt flows down to the bottom of the VK tube through layers of baffles, and is taken out by the discharge pump to maintain the liquid level in the tube. The polymerization time is 14 hours. The obtained polymer melt is washed with water, cut into pellets, and dried in vacuum to remove moist...

Embodiment 3

[0055]

[0056] Such as figure 1 Shown: Stir and mix the above materials in the storage tank evenly, and continuously send the above materials into the straight VK pipe through the feed pump, and the materials are polymerized by the ring-opening agent. The temperature control in the polymerization reaction is divided into three parts In the first stage, the material is in the upper section of the straight VK tube, and the temperature is controlled between 230-270°C; the middle section of the straight VK tube, the temperature is controlled between 240-260°C; the temperature in the lower section of the straight VK tube is controlled at 235-260°C In between, the polymer melt flows down to the bottom of the VK tube through layers of baffles, and is taken out by the discharge pump to maintain the liquid level in the tube. The polymerization time is 16 hours. The obtained polymer melt is washed with water, cut into pellets, and dried in vacuum to remove moisture and small molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com