Functional recycled nylon 6 fiber, preparing method thereof and fabric

A functional, nylon technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve the problems of difficult wearing experience on the consumer side and difficult to promote and apply on the manufacturing side. Increase enthusiasm and facilitate the effect of promoting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a preparation method of functional regenerated nylon 6 fiber, comprising the following steps:

[0032] Nylon 6 waste is regenerated and granulated after pretreatment to obtain regenerated nylon granules;

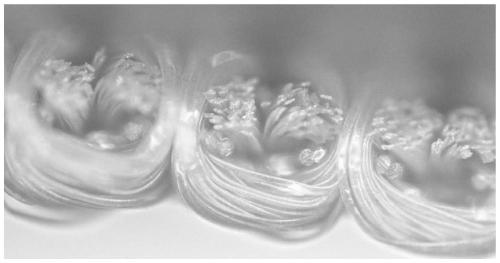

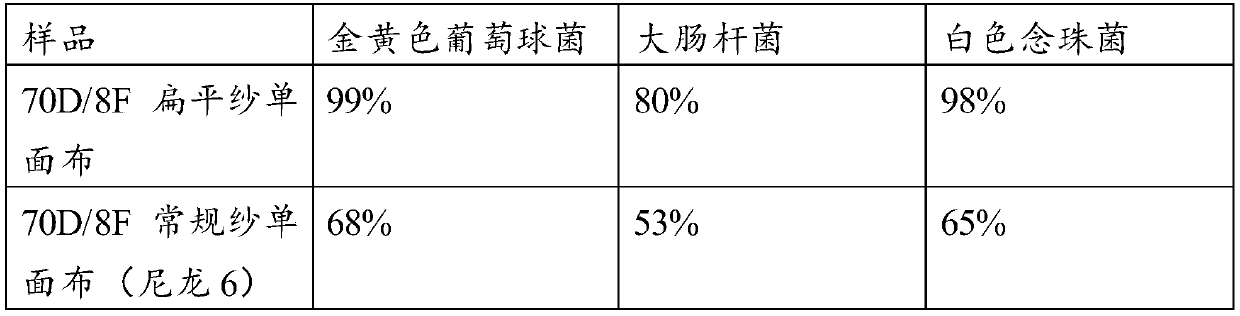

[0033] The regenerated nylon particles are optionally mixed with additives, and then melt-spun. The melt-spun process adopts a flat inline spinneret to obtain functional regenerated nylon 6 fibers.

[0034] In the embodiment of the present invention, the recycled nylon waste is first regenerated and granulated, and the process route is as follows: nylon waste collection-crushing-cleaning-drying-granulator extrusion-cooling granulation-cutting.

[0035] Wherein, the nylon waste mainly adopts leftover material and waste in the production process of nylon 6. In the present invention, a crusher can be used to crush (or crush) the collected nylon waste, and the output is generally fragments of 2cm-3cm. The pretreatment pro...

Embodiment 1

[0048] 1. Regranulation of recycled materials:

[0049] Nylon 6 waste is regenerated and granulated, and the process route is as follows: nylon waste collection-crushing-cleaning-drying-granulator extrusion-cooling granulation-cutting. Among them, the nylon waste is leftover material and waste in the production process of nylon 6.

[0050] The collected nylon 6 waste is crushed by a crusher, and the output is 2-3cm fragments. The debris is cleaned in the primary washing tank to remove most of the dust, silt and other impurities mixed in the waste, mixed by the mixer, and then enters the centrifuge for dehydration after the first cleaning and the second cleaning, and then enters the dryer Drying, drying temperature 80-90 ℃.

[0051] The dried fragments (the raw materials after the above treatment maintain more than 95% of the weight before treatment, and the above treatment is mainly physical treatment) enter the twin-screw wire drawing machine from the feed port of the granu...

Embodiment 2

[0073] 1. Regranulation of recycled materials:

[0074] Nylon 6 waste is regenerated and granulated, and the process route is as follows: nylon waste collection-crushing-cleaning-drying-granulator extrusion-cooling granulation-cutting. Among them, the nylon waste is leftover material and waste in the nylon production process.

[0075] The collected nylon 6 waste is crushed by a crusher, and the output is 2-3cm fragments. The debris is cleaned in the primary washing tank to remove most of the dust, silt and other impurities mixed in the waste, mixed by the mixer, and then enters the centrifuge for dehydration after the first cleaning and the second cleaning, and then enters the dryer Drying, drying temperature 80-90 ℃.

[0076] The dried fragments enter the twin-screw wire drawing machine from the feed port of the granulator (the diameter of the screw is 35mm, the ratio of length to diameter is 36:1). : 230-235°C; second stage temperature: 277-232°C; third stage temperature:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com