Preparation method of durable and efficient antibacterial nylon 6 fiber and product prepared from fiber

A fiber and nylon technology, which is applied in the field of long-lasting and efficient antibacterial nylon 6 fiber preparation, can solve the problems that affect the hand feel and mechanical properties of nylon 6 fiber, affect the long-term application of nylon 6 fiber, and the amount of antibacterial agent should not be too much, so as to achieve improvement The effect of forming stability, improving utilization efficiency, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

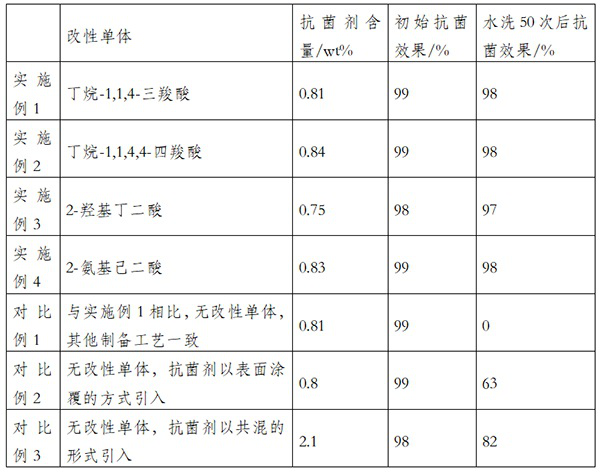

Examples

Embodiment 1

[0039] This embodiment provides a kind of preparation method of durable high-efficiency antibacterial nylon 6 fiber, the steps are:

[0040] (1) Dissolve butane-1,1,4-tricarboxylic acid and butanediamine in water to prepare a 50wt% solution. After stirring at 70°C for 70 minutes, the resulting mixed solution is cooled and allowed to stand to precipitate crystals ( The cooling temperature is 35°C, and the standing time is 3 hours), filtered, washed and dried to obtain the modified salt, and the molar ratio of amine group to carboxyl group is 1.001:1;

[0041](2) After mixing caprolactam, water, and 4-amino-2,2,6,6-tetramethylpiperidine uniformly, the raw materials for the ring-opening reaction were prepared, and the ring-opening reaction was used to obtain the nylon 6 prepolymer; among them, water was added The amount is 0.5wt% relative to the mass of caprolactam; the amount of 4-amino-2,2,6,6-tetramethylpiperidine added is 0.2% relative to the mass of caprolactam, and the ring...

Embodiment 2

[0047] This embodiment provides a kind of preparation method of durable high-efficiency antibacterial nylon 6 fiber, the steps are:

[0048] (1) Dissolve butane-1,1,4,4-tetracarboxylic acid and butanediamine in alcohol to prepare a 65wt% solution. After stirring at 60°C for 100 minutes, cool the resulting mixed solution and let it stand Precipitate crystals (cooling temperature is 5°C, standing time is 3 hours), filter, wash and dry the obtained crystals to obtain modified salt, the molar ratio of amine group to carboxyl group is 1.0005:1;

[0049] (2) After mixing caprolactam, water, and bis(2,2,6,6-tetramethyl-3-piperidinylamino)-isophthalamide evenly, the raw material for the ring-opening reaction was prepared, and the ring-opening reaction obtained Nylon 6 prepolymer; Wherein, water addition is 2wt% relative to caprolactam mass; Two (2,2,6,6-tetramethyl-3-piperidinyl amino)-isophthalamide addition is Relative to 0.4% of the mass of caprolactam, the ring-opening reaction t...

Embodiment 3

[0055] This embodiment provides a kind of preparation method of durable high-efficiency antibacterial nylon 6 fiber, the steps are:

[0056] (1) Dissolve 2-hydroxysuccinic acid and butanediamine in methanol to prepare a 70wt% solution. After stirring at 55°C for 100 minutes, cool the resulting mixed solution to precipitate crystals (cooling temperature is 4°C , the standing time is 5 hours), filtered, and the obtained crystals were washed and dried to obtain the modified salt, and the molar ratio of amine group to carboxyl group was 1.002:1;

[0057] (2) After uniformly mixing caprolactam, water, and antioxidant 1010, the ring-opening reaction raw material is obtained, and the ring-opening reaction is used to obtain a nylon 6 prepolymer; wherein, the amount of water added is 1wt% relative to the mass of caprolactam; the antioxidant The amount of 1010 added is 0.3% relative to the mass of caprolactam, the ring-opening reaction temperature is 245°C, the pressure is 0.38MPa, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com