Wiring harness automatic penetration sleeve device

A casing equipment and automatic threading technology, which is applied in the direction of cable laying equipment, cable installation devices, electrical components, etc., can solve the problems of workers' wrist injuries, low efficiency, and physical exertion, so as to reduce labor costs, avoid damage, and improve the surface The effect of a large coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

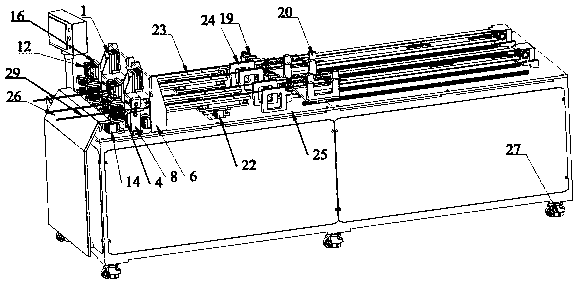

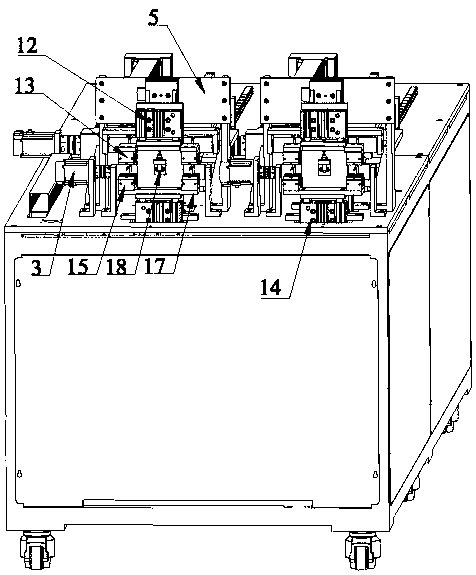

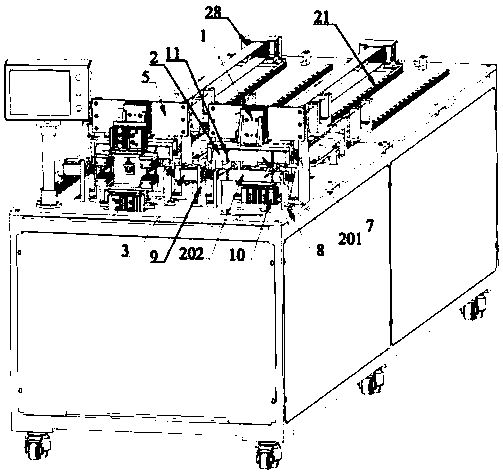

[0032] Depend on figure 1 As shown, this patent application includes: including: the equipment base, and the sleeve automatic feeding and wire harness feeding part fixed on the equipment base, the sleeve non-injury gripping part, the wire harness penetration and the finished product delivery integration In the module part, the right side of the sleeve automatic feeding and wire harness feeding part is the wire harness penetration and finished product delivery integrated module part, which completes the transportation of PVC sleeves, the delivery of wire harnesses and the penetration of wire harnesses into PVC sleeves; the sleeves are automatically fed into And the left side of the wiring harness feeding part is the casing non-injury gripping part, which is used to grasp the PVC casing, among which, the casing automatic feeding part, the wire harness fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com