Particle rubber roll and manufacturing method thereof

A manufacturing method and technology of rubber rollers, applied in the field of cold-rolled steel plate manufacturing, can solve the problems of reduced service life of rubber rollers, steel plate product quality problems, easy grinding of contact points, etc. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

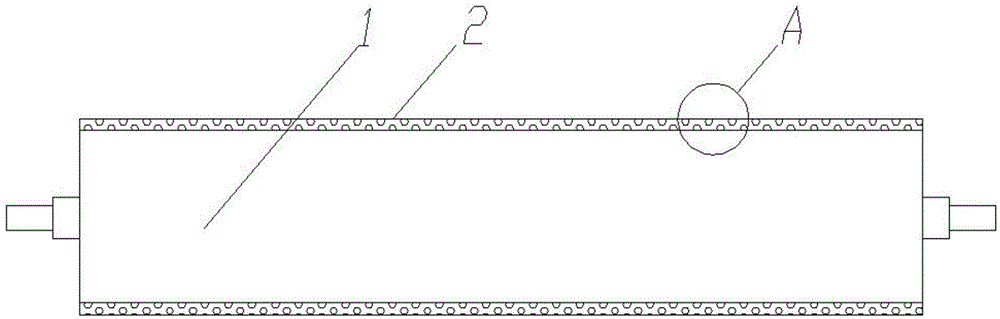

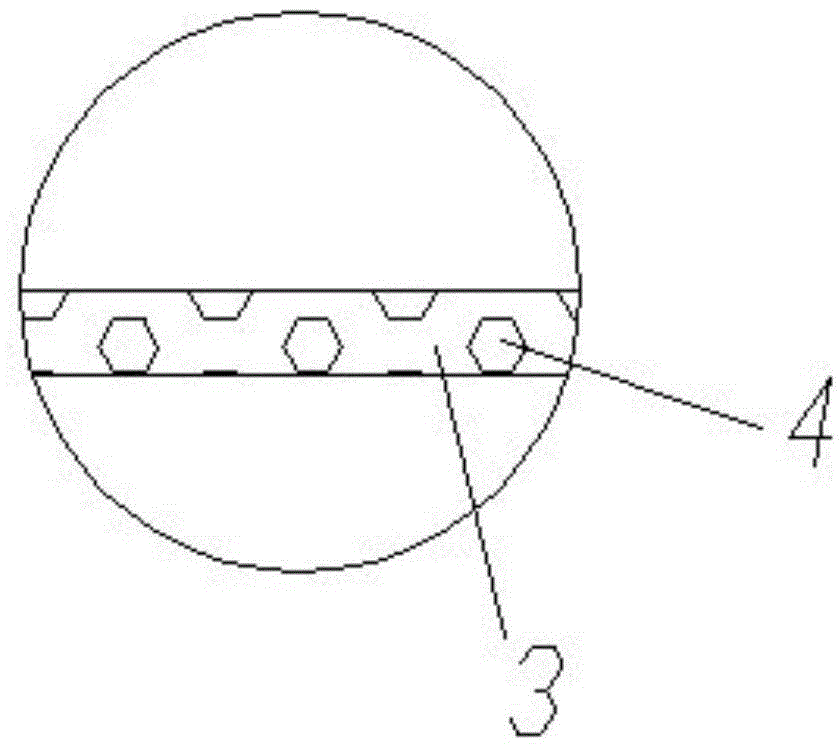

[0021] according to Figures 1 to 2 , the present invention provides a particle rubber roller, comprising a roller body 1, the surface of the roller body is coated with a rubber layer 2, the outer surface of the rubber layer is a smooth curved surface, and the rubber layer is composed of base rubber 3 and several rubber particles 4, The rubber particles are evenly distributed in the base rubber, and the Shore hardness of the rubber particles is 15 degrees higher than that of the base rubber. The particle size of the rubber particles can be appropriately changed according to the change of the distribution density of the rubber particles on the rubber layer.

[0022] A method for manufacturing a granular rubber roller, comprising the following steps:

[0023] a. To manufacture semi-vulcanized rubber granules, add the rubber granules into the molten base rubber and mix them evenly;

[0024] B, forming the mixture of the rubber particles obtained in step a and the base rubber in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com