Preparation method of star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt and production method of waterproof coiled material

A technology of modified asphalt and asphalt, which is applied in building insulation materials, building components, buildings, etc. It can solve the problems of difficult asphalt processing and difficult asphalt fusion, and achieve high surface friction coefficient, good low temperature performance and excellent tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

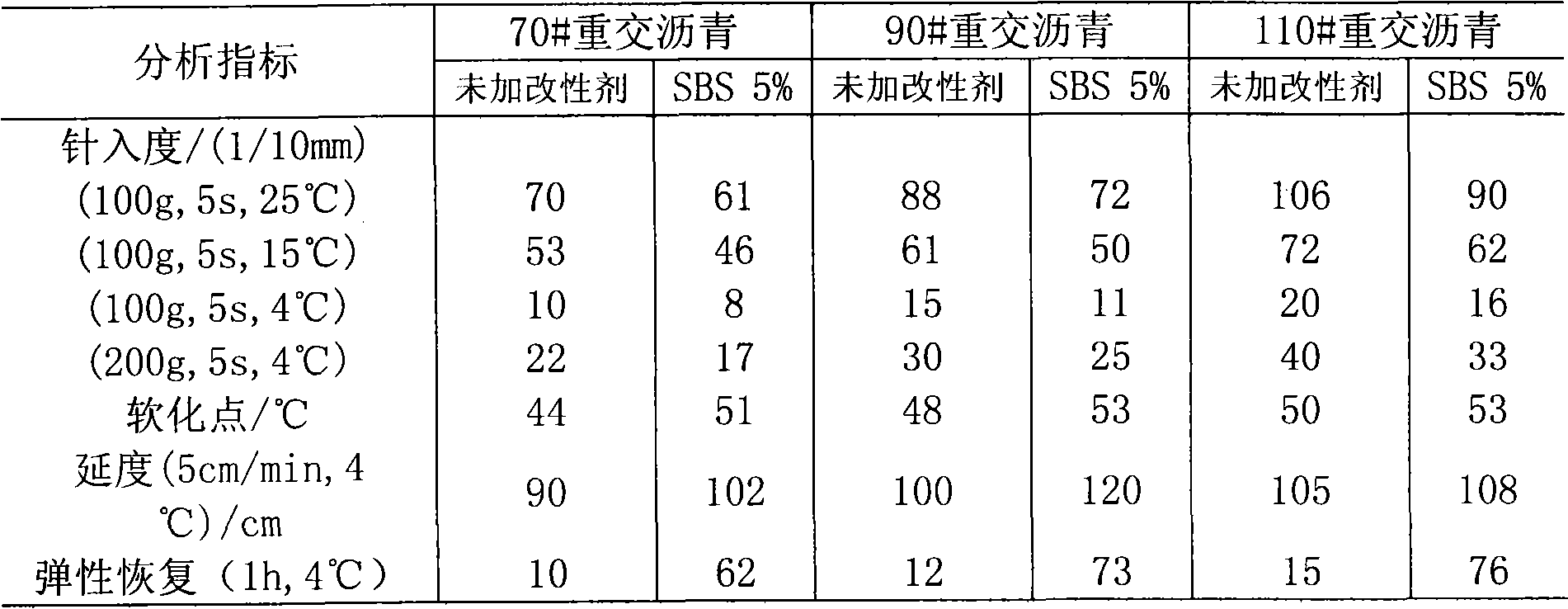

[0021] Select star-shaped SBS with a molecular weight of 100,000 and a block ratio of 30-40 and No. 200 gasoline, with a mass ratio of 1:2. Type SBS, stirring and soaking for 10-36 hours, so that the star-shaped SBS is fully swollen; in the asphalt mixing tank, add 70-130 heavy-duty asphalt, the weight of the asphalt is 45%; the weight of the swollen star-shaped SBS is 5, stir and heat To 150 ~ 200 ℃, then add swollen star-shaped SBS, anti-butyl naphthenate 3%, ordinary rubber powder 10%, phosphite tris (2,4-di-tert-butylphenyl) 3%; calcium carbonate Powder 34%, modified for 30 minutes to 150 minutes, that is, a uniform and stable modified asphalt is obtained, and one side is covered on the high-density polyethylene base to make a coil.

Embodiment 2

[0023] Select star-shaped SBS with a molecular weight of 200,000 and a block ratio of 40-60 and No. 0 diesel oil. The mass ratio is 1:3. Type SBS, stirring and soaking for 20-40 hours, so that the star-shaped SBS is fully swollen; in the asphalt mixing tank, add 70-130# heavy traffic asphalt, the weight of the asphalt is 52%; the weight of the swollen star-shaped SBS is 8, stir and heat To 150 ~ 200 ℃, then add swollen star-shaped SBS, anti-butyl naphthenate 3%, synthetic rubber powder 12%, functional additives carboxypolysiloxane 2%, polymethylethoxysilane 3% , tris(2,4-di-tert-butylphenyl) phosphite 3%; talcum powder 17%, modified for 30min to 150min, to obtain uniform and stable modified asphalt, double-sided covered on the polyethylene base, Made into coils.

Embodiment 3

[0025]Select star-shaped SBS and kerosene with a molecular weight of 250,000 and a block ratio of 40-60. The mass ratio is 1:4. Soak for 50 hours to fully swell the star-shaped SBS; add 70-130# heavy-duty asphalt to the asphalt mixing tank, the weight of the asphalt is 38%; the weight of the swollen star-shaped SBS is 12%, stir and heat to 150-200°C , then add swollen star-shaped SBS, 2% anti-butyl naphthenate, 15% synthetic rubber powder, 6% mixture of functional additive cyclomethicone and polynaphthalene sulfonic acid sodium salt, phosphite tri( 5% of 2,4-di-tert-butylphenyl) ester; 22% of asbestos powder, modified for 30 minutes to 150 minutes to obtain uniform and stable modified asphalt, and the modified asphalt is used for the waterproof wall of the basement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com