Manufacturing method of porous bottom surface of zirconium oxide ceramic bracket

A technology of zirconia ceramics and manufacturing methods, applied in the direction of brackets, etc., can solve the problems of poor bonding force and low manufacturing cost, and achieve the effect of improving bonding force, low manufacturing cost, and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

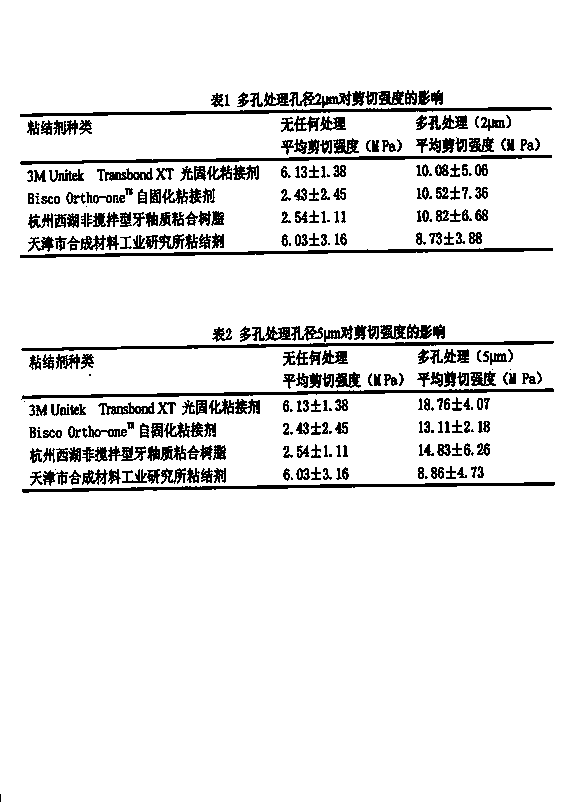

[0011] The zirconia:silica was mixed and ball milled according to the mass ratio of 10:1 for 20 hours, and the particle size distribution range of coarse zirconia was 0.05-0.33mm. The solution was prepared with a mass percentage concentration of 0.04%, and 0.2ml of this solution was evenly coated Lay it on the bottom of the zirconia ceramic bracket, sinter the coated zirconia ceramic bracket at 1320℃ for 2 hours, the particle size after sintering is 2μm, respectively, with 3M Unitek Transbond XT light-curing adhesive, Bisco Ortho-one TM Self-curing adhesive, Hangzhou West Lake non-stirring enamel composite resin, and Tianjin Institute of Synthetic Materials Industry Adhesive for bonding, each made 5 bonding samples. After making the sample, place it in artificial saliva at 37°C for 24 hours. The universal serving machine was subjected to a shear test, and the test results are shown in Table 1.

[0012] The adhesion between the ceramic bracket and the tooth enamel obtained by the...

Embodiment 2

[0014] The zirconia:silica was mixed and ball milled for 10 hours according to the mass ratio of 10:1, the particle size distribution range of coarse zirconia was 0.05-0.33mm, and the solution was prepared with a mass percentage concentration of 0.04%, and the solution was 0.2ml uniform Coated on the bottom of the zirconia ceramic bracket, and sintered the coated zirconia ceramic bracket at 1320℃ for 2 hours, the particle size after sintering is 5 μm, respectively, with 3M Unitek Transbond XT light-curing adhesive, Bisco Ortho- one TM Self-curing adhesive, Hangzhou West Lake non-stirring enamel adhesive resin, Tianjin Institute of Synthetic Materials Industry Adhesive for bonding, each made 5 bonding samples. After making the sample, place it in artificial saliva at 37°C for 24 hours. The universal serving machine was subjected to a shear test, and the test results are shown in Table 2.

[0015] The adhesion between the ceramic bracket and the tooth enamel obtained by the above...

Embodiment 3

[0017] The zirconia:alumina:silica was mixed and ball milled according to the mass ratio of 10:0.1:1 for 20 hours. The particle size distribution range of coarse zirconia was 0.05-0.33mm, and the solution was formulated into a solution with a mass percentage concentration of 0.01%. Other steps The same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com