Skin-friendly wood-plastic composite board and molding process thereof

A technology of wood-plastic composite and molding process, which is applied in the field of wood-plastic composite board preparation, which can solve the problems of composite materials such as easy mildew, hard surface texture, and small friction, so as to ensure long-term stable use, good anti-friction performance, and low friction. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

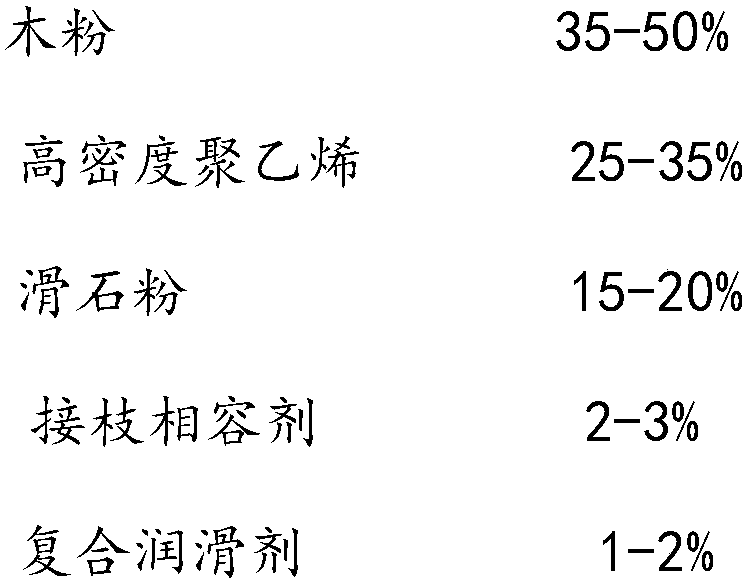

[0030] A skin-friendly wood-plastic composite board, comprising the following components in mass fractions:

[0031]

[0032]

[0033] The preparation process of the elastomeric material is as follows:

[0034] Step 1: Take 3kg of polypropylene glycol and add it to the reaction vessel, heat it up to 60-70°C, then add 2.19kg of diisocyanic acid into it, raise the temperature to 100-110°C and stir for 2-2.5h, then add it to the reaction vessel 27g nano-lanthanum oxide, stir and mix evenly and keep the temperature constant for later use;

[0035] Step 2: After heating and melting 700g of sarin resin at 130°C, add 84g of fumed silica and 57.4g of trimethyl aluminate into it and stir and mix evenly to obtain a mixed solution. Take 690g of the mixed solution and add it to the In the reaction vessel, stir and mix evenly at a constant temperature to obtain a prepolymerized composite solution;

[0036] Step 3: Add 3L of pre-polymerized composite solution into the vulcanizer, th...

Embodiment 2

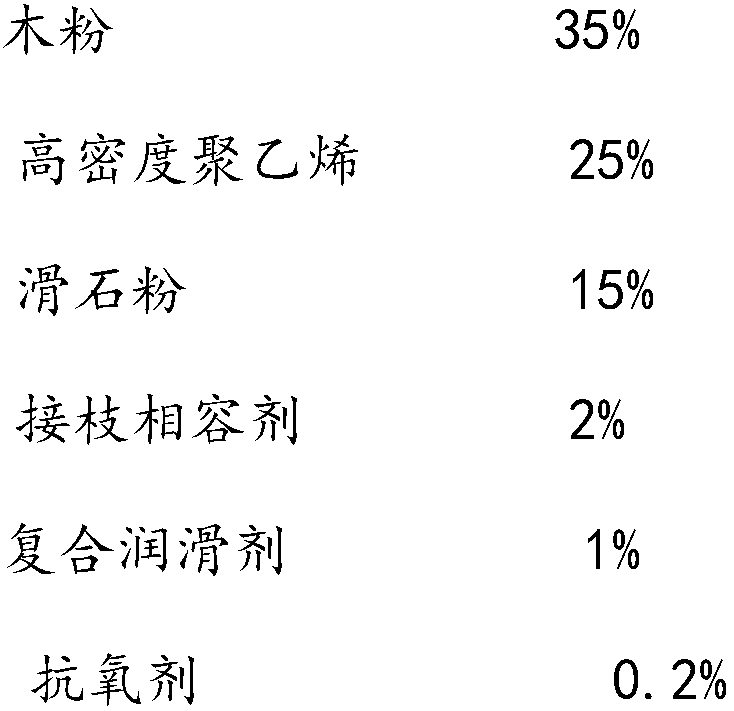

[0044] A skin-friendly wood-plastic composite board, comprising the following components in mass fractions:

[0045]

[0046] The preparation process of the elastomeric material is as follows:

[0047] Step 1: Take 3kg of polypropylene glycol and add it to the reaction vessel, heat it up to 60-70°C, then add 2.28kg of diisocyanic acid into it, raise the temperature to 100-110°C and stir for 2-2.5h, then add it to the reaction vessel 36g of nano-lanthanum oxide, stir and mix evenly and keep the temperature constant for later use;

[0048] Step 2: After heating and melting 700g of sarin resin at 130°C, add 91g of fumed silica and 58.8g of trimethyl aluminate into it, stir and mix evenly to obtain a mixed solution, and add 780g of the mixed solution to the reaction in step 1 In the container, stir and mix evenly at a constant temperature to obtain a prepolymerized compound solution;

[0049] Step 3: Add 3L of pre-polymerization composite solution into the vulcanizer, then ad...

Embodiment 3

[0057] A skin-friendly wood-plastic composite board, comprising the following components in mass fractions:

[0058]

[0059] The preparation process of the elastomeric material is as follows:

[0060] Step 1: Take 3kg of polypropylene glycol and add it to the reaction vessel, heat it up to 60-70°C, then add 2.23kg of diisocyanic acid into it, raise the temperature to 100-110°C and stir for 2-2.5h, then pour it into the reaction vessel Add 34g of nano-lanthanum oxide, stir and mix evenly and keep the temperature constant for later use;

[0061] Step 2: After heating and melting 700g of sarin resin at 130°C, add 89g of fumed silica and 58.3g of trimethyl aluminate to it and stir and mix evenly to obtain a mixed solution. Add 760g of the mixed solution to the reaction in step 1 In the container, stir and mix evenly at a constant temperature to obtain a prepolymerized compound solution;

[0062] Step 3: Add 3L of pre-polymerization composite solution into the vulcanizer, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com