Textile yarn waxing device

A technology of spinning yarn and waxing device, applied in textiles and papermaking, etc., can solve the problems of unmaintained waxing force, uneven waxing, no preloading device, etc., and achieves increased surface friction coefficient and light weight. , The effect of preventing the yarn from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of a textile yarn waxing device of the present invention will be described in detail below in conjunction with the accompanying drawings.

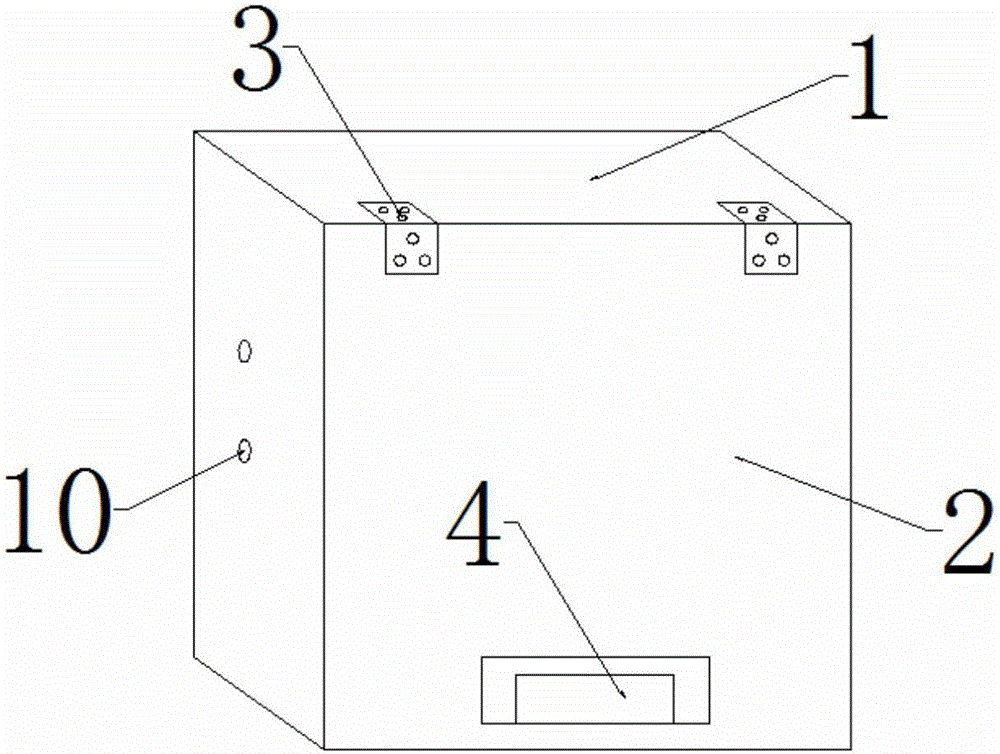

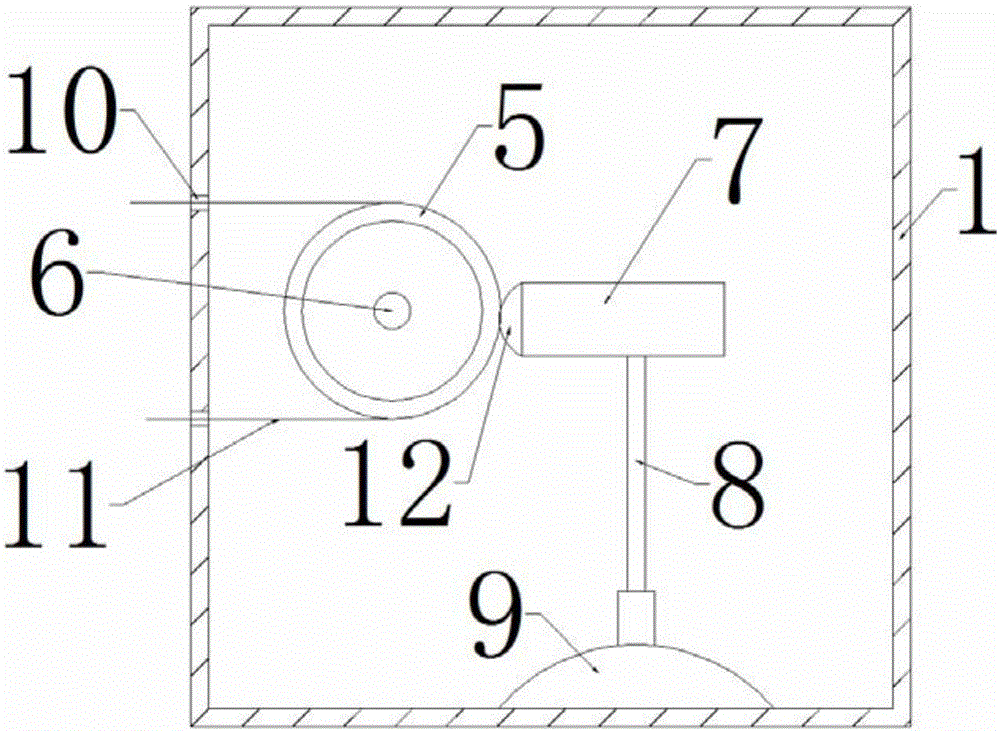

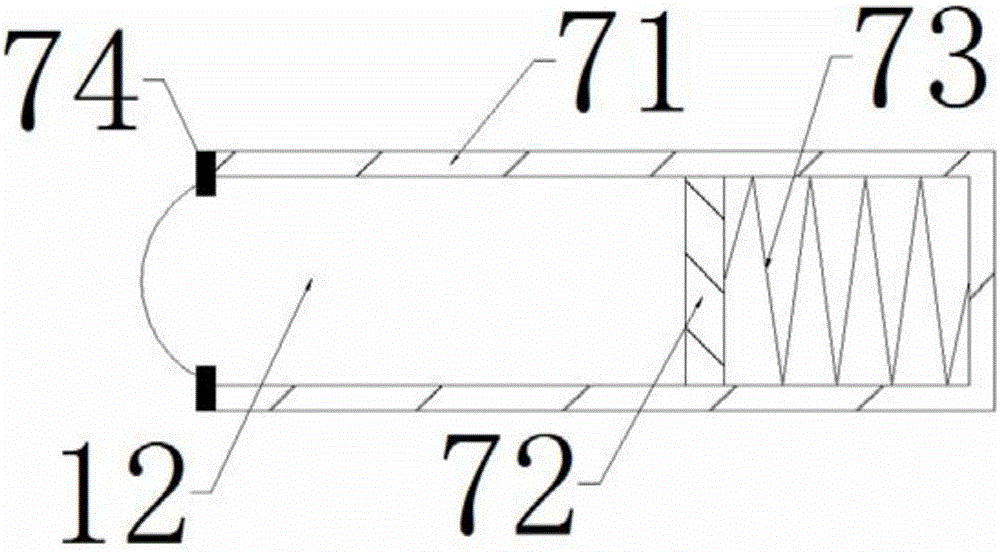

[0017] figure 1 and figure 2 A specific embodiment of a textile yarn waxing device of the present invention is shown: the textile yarn waxing device includes a housing 1, a panel 2, a hinge 3, a handle 4, a yarn feeding wheel 5, a rotating shaft 6, and a waxing device 7 , connecting rod 8, pneumatic device 9, threading holes 10, solid wax 12, the textile yarn waxing device includes a rectangular housing 1, the housing 1 is cast from aluminum alloy, light in weight and good in shock absorption, It can ensure the stable operation of the waxing device. There is a panel 2 on the front of the housing 1, which can prevent dust from entering the device and ensure the quality of waxing. The panel 2 is made of structural steel. The bottom of the panel 2 is provided with a handle 4. The body 1 is connected, the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com