Railroad transport crawler belt equipment non-overrun device cloth layer rubber bearing body

A technology for railway transportation and pressure-bearing bodies, which is applied in the direction of natural rubber adhesives, adhesives, and layered products. Problems such as large difference in cold resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

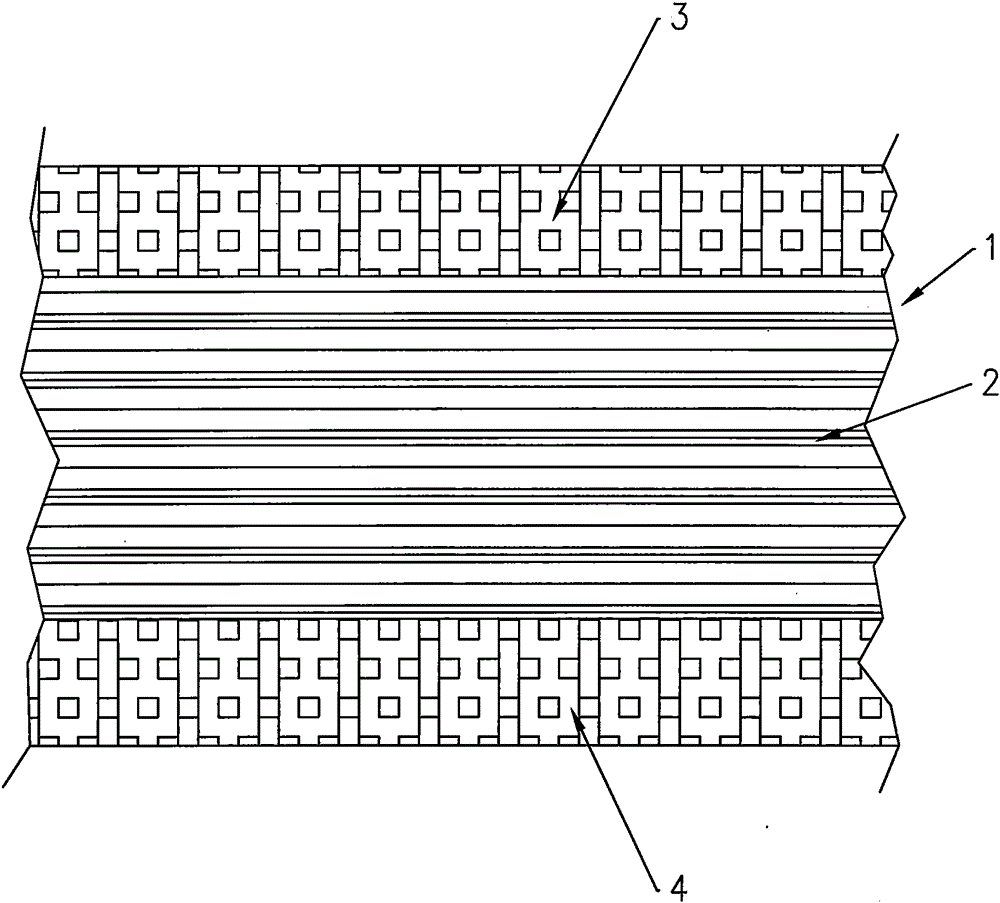

[0019] Such as figure 1 As shown, the railway transport crawler equipment of the present invention is equipped with a cloth layer rubber pressure bearing body for the non-overrunning device, including a rectangular pad, the pad includes a strength layer 1 arranged in the horizontal direction, and the strength layer 1 includes 3- 5 layers of EP canvas 2, the adjacent surfaces of 3-5 layers of EP canvas 2 are bonded and connected with 401 adhesive, the upper surface of strength layer 1 is bonded with glue layer 3 and super glue layer 1 with 401 adhesive The lower surface is bonded with a lower glue layer 4 with 401 adhesive;

[0020] The thickness of the strength layer 1 is 60-80mm, the thickness of the upper glue layer 3 is 30-50mm, and the thickness of the lower glue layer 4 is 20-40mm;

[0021] Gluing layer 3 adopts following steps to make:

[0022] A. Mix the following raw materials according to the ratio:

[0023] 80-82 parts by weight of natural rubber, 2-3 parts by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com