Wharve of spun yarn spindle

A spindle disk and spindle technology, applied in the direction of textiles and papermaking, etc., can solve the problems of increasing spindle belt tension, reducing yarn quality, and increasing energy consumption of spinning frame, so as to increase friction coefficient, improve yarn quality, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

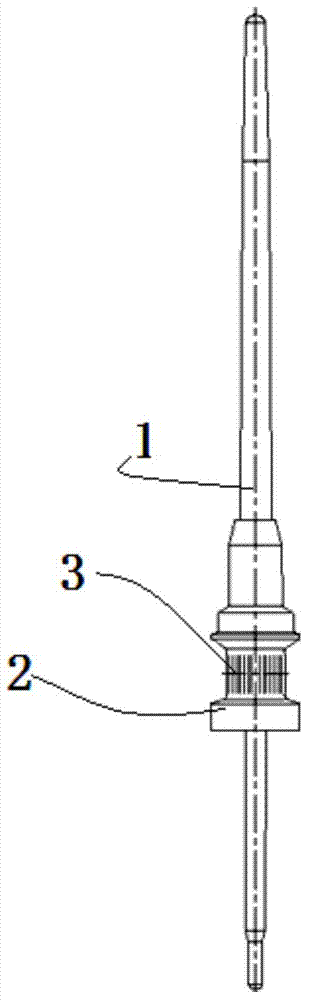

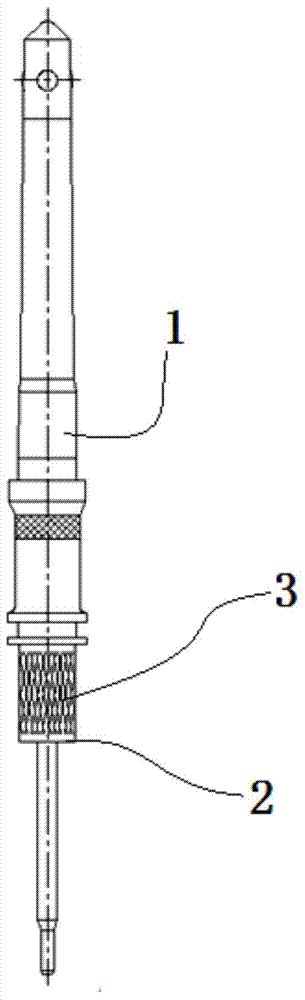

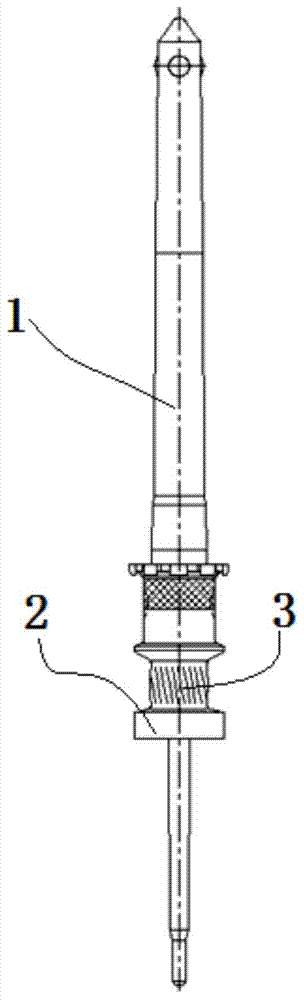

[0026] Such as figure 1 , figure 2 and image 3 As shown, the spinning spindle includes a spindle rod 1, and the spindle disk 2 is arranged on the spindle rod 1. The spindle disk 2 is connected with the spindle belt that drives the spinning spindle to rotate, and the contact surface between the spindle disk 2 and the spindle belt Anti-slip structure 3 is provided on it.

[0027] Preferably, the anti-slip structure 3 is a corrugated structure provided on the surface of the spindle disc 2 .

[0028] Such as figure 1 As shown, as the first preferred solution, the flute structure is a straight line flute uniformly distributed on the surface of the spindle disc 2 along the axial direction of the spindle rod 1 .

[0029] Such as figure 2 As shown, as the second preferred solution, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com