High-wear-resistance rubber friction layer for folder gluer conveying belt and preparation method of rubber friction layer

A high wear resistance, folder gluer technology, applied in the field of rubber materials, can solve the problems of small surface friction coefficient, general wear resistance, general strength, etc., to increase the surface friction coefficient, improve processing performance, improve compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Preparation and mastication of raw rubber

[0046] Plastication of butadiene rubber: weigh butadiene rubber (BR9000), adjust the roller distance of the open rubber mixer to 0.5mm, put the butadiene rubber on the roller, let it fall freely, and add peptizer I (SJ-103). Repeat the thin pass six times and then use it.

[0047] Mastication of natural rubber: Weigh natural rubber (constant viscosity CV60), add peptizer II (SJ-103), and the operation process is the same as above.

[0048] Plastication of nitrile rubber: weigh nitrile rubber (NBR220), add peptizer III (SJ-103), and the operation process is the same as above.

[0049] 2) Mixing of glue

[0050] Carry out mixing according to the raw material proportioning of table 1, specifically comprise the following steps:

[0051] Put the butadiene rubber, natural rubber and nitrile rubber masticated in step 1) into the internal mixer, press down the top bolt, the pressure is 0.8MPa, and banbury for 1.5 minutes, so th...

Embodiment 2-3

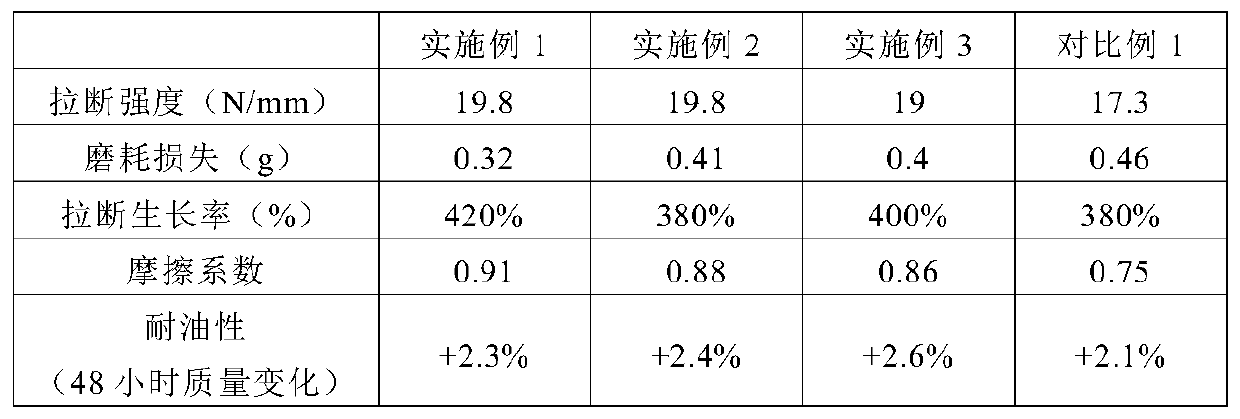

[0075] According to the preparation of raw materials in Table 1, the rubber friction layer was prepared according to the same operation as Step 1)-Step 4) of Example 1, and the same performance test was carried out. See Table 2 for the performance test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com