Electrochemical corrosion apparatus and electrochemical corrosion method of reinforcing steel bar in seawater full immersion zone reinforced concrete

A reinforced concrete, electrochemical technology, applied in the field of anti-corrosion and system, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

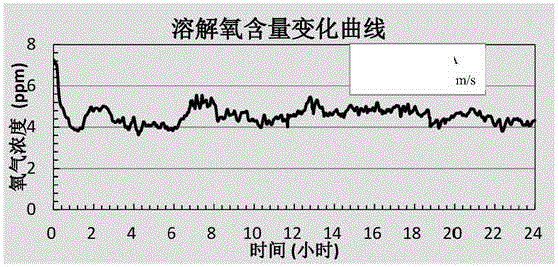

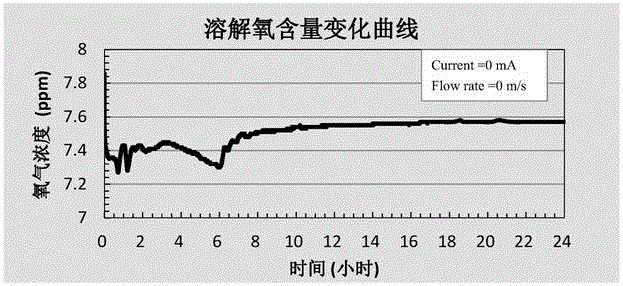

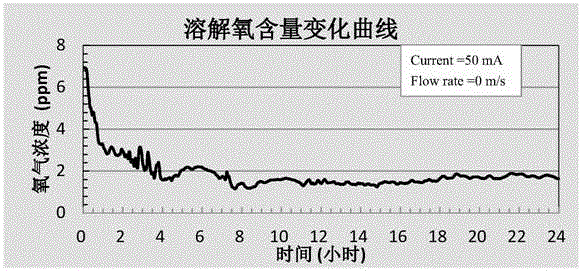

[0037] Such as Figure 1-Figure 8 Shown:

[0038] The present invention proposes a new method to consume the oxygen in the vicinity of the steel bars in water to prevent the steel bars from corroding.

[0039] A conductive low-carbon steel mesh 1 is placed near the concrete surface as a cathode, a titanium electrode 2 is used as an auxiliary anode, and a DC power supply 3 is used for power supply respectively. Together with seawater they form an electrochemical oxygen filter such as figure 1 shown.

[0040] During the electrification process, a mild steel mesh located near the concrete surface acts as a cathode where oxygen is converted into hydroxide ions and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com