A detection method for rotationally symmetric free-form surface lens

A technology of rotational symmetry and curved surface lens, which is applied in the direction of testing optical properties, can solve the problems of free-form surface detection, and achieve the effect of reducing material cost, short processing cycle and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

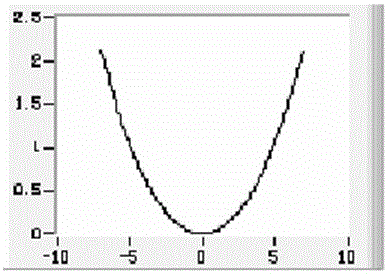

[0023] In this embodiment, a reflector for detection is designed for a plano-convex lens with a diameter of 30 mm and a plano-convex lens with a high-order aspheric surface on one side. The equation of the high-order aspheric surface of the lens to be tested is:

[0024] ;

[0025] in:

[0026] c=1 / R

[0027] R=20.4

[0028] k=-1.035356

[0029] a2=5.685242e-006

[0030] a3=-7.934483e-010

[0031] a4=-3.635248e-012

[0032] a5=5.883743e-016

[0033] The remaining coefficients are 0;

[0034] The refractive index of the material is n=1.788.

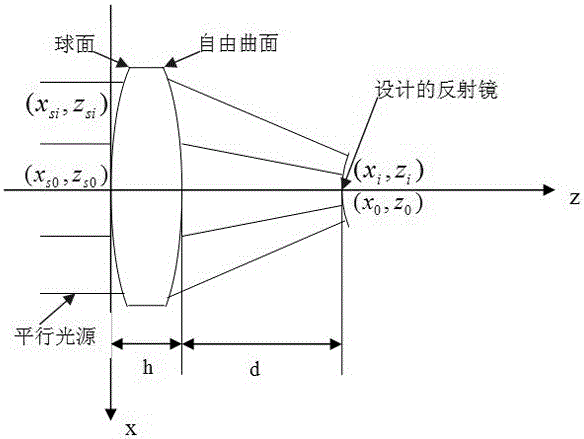

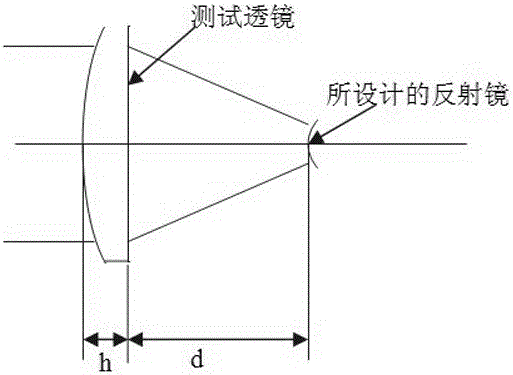

[0035] See attached figure 1 , which is a schematic diagram of the design of the reflector used for the detection of the rotationally symmetric free-form surface lens provided in this embodiment; the specific implementation steps involved in the reflector are as follows:

[0036] 1. Use parallel light as the light source. The incident direction of the parallel light source is parallel to the Z-axis, and the incident direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com