Aluminum alloy powder core wire for arc welding additive manufacturing

An additive manufacturing, aluminum alloy powder technology, applied in manufacturing tools, welding/cutting media/materials, welding media, etc., can solve the problems of long processing cycle, many pores in the finished product, difficult component adjustment, etc., to reduce pores, reduce Porosity, the effect of avoiding hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

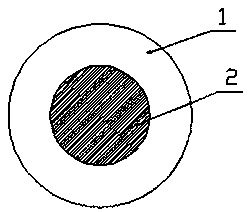

Image

Examples

Embodiment 1

[0029] The aluminum strip made of 5056 aluminum alloy is rolled into a U-shaped tube through the forming groove, and then filled with powder core in the U-shaped tube. The mass of the powder core accounts for 8% of the total mass of the aluminum alloy powder core wire. Wherein, the composition of the powder core is: calcium-silicon alloy powder (the mass percentage of Ca in the calcium-silicon alloy powder is 31.5%, the mass percentage of Si is 62.5%, the mass percentage of C is 0.5%, and the balance Fe), aluminum powder, titanium powder and silicon-zirconium alloy (the mass percentage content of Zr in the silicon-zirconium alloy powder is 38.4%, the mass percentage content of Si is 50.8%, the mass percentage content of C is 0.5%, and the rest Fe), chromium powder, and manganese powder; among them: the content of Ca element accounts for 2.0% of the total mass of the powder core, the content of titanium element accounts for 10% of the total mass of the powder core, and the conte...

Embodiment 2

[0032] The aluminum strip made of 5056 aluminum alloy is rolled into a U-shaped tube through the forming groove, and then filled with powder core in the U-shaped tube. The mass of the powder core accounts for 8% of the total mass of the aluminum alloy powder core wire. Wherein, the composition of the powder core is: silicon-barium alloy powder (the mass percentage of Ba in the silicon-barium alloy powder is 35.0%, the mass percentage of Si is 35.0%, the mass percentage of C is 0.3%, and the balance Fe), aluminum powder, titanium powder and silicon-zirconium alloy (the mass percentage content of Zr in the silicon-zirconium alloy powder is 38.4%, the mass percentage content of Si is 50.8%, the mass percentage content of C is 0.5%, and the rest Fe), chromium powder, and manganese powder; among them: the content of Ba element accounts for 1.5% of the total mass of the powder core, the content of titanium element accounts for 10% of the total mass of the powder core, and the content...

Embodiment 3

[0035]The aluminum strip made of 5056 aluminum alloy is rolled into a U-shaped tube through the forming groove, and then filled with powder core in the U-shaped tube. The mass of the powder core accounts for 8% of the total mass of the aluminum alloy powder core wire. Wherein, the composition of the powder core is: silicon-strontium alloy powder (the mass percentage of Sr in the silicon-strontium alloy powder is 52%, the mass percentage of Si is 45%, the mass percentage of S is 0.5%, the mass percentage of Al The mass percentage content is 2%, the balance is C), aluminum powder, titanium powder, silicon-zirconium alloy (the mass percentage content of Zr in the silicon-zirconium alloy powder is 38.4%, the mass percentage content of Si is 50.8%, and C The mass percentage content is 0.5%, and the balance is Fe), chromium powder, and manganese powder; wherein, the content of silicon-strontium alloy powder accounts for 3.0% of the total mass of the powder core, and the content of ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com