Super-pressure hydrogen cylinder manufacture method

A manufacturing method, technology of hydrogen cylinders, applied to container filling methods, equipment for loading into pressure vessels, pressure vessels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

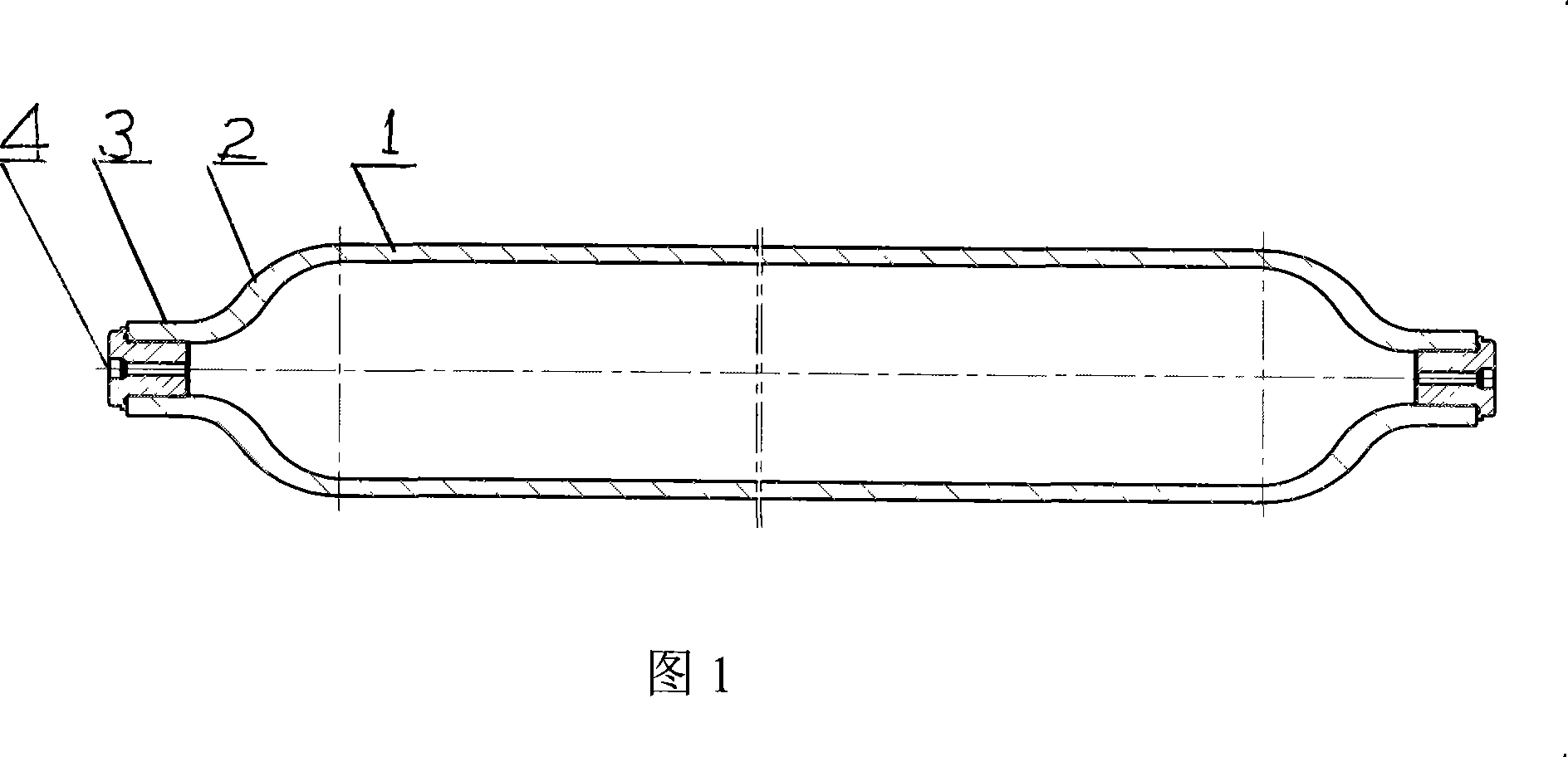

Image

Examples

Embodiment Construction

[0022] The biggest technical obstacle in the manufacture of ultra-high pressure hydrogen cylinders is the possible "hydrogen embrittlement". Through a large number of destructive experiments and rigorous calculations, it is proved that limiting and controlling the content of sulfur and phosphorus in basic materials is one of the key measures to prevent "hydrogen embrittlement". Although chrome-molybdenum steel has excellent comprehensive properties and ideal physical and chemical indicators. After quenching and tempering, it can still maintain good plasticity and sufficient toughness at a high strength level. But in the hydrogen gas of 45MPa, the sulfur and phosphorus content in the substrate should not exceed 0.010% and 0.020% respectively, so as to ensure that the hydrogenation reaction process is inevitable, but the consequences of the reaction speed will not cause the bottle body to suffer from "hydrogen" brittle phenomenon". Simultaneously, implementing stricter physica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com