Ultra-high pressure hydrogen storage container

A hydrogen storage container, ultra-high pressure technology, applied in the direction of pressure vessels, container filling methods, container discharge methods, etc., can solve problems such as plastic collapse, hydrogen embrittlement, ratchet failure, etc., to achieve convenient disassembly and assembly, ensure safe use requirements, The effect of increasing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

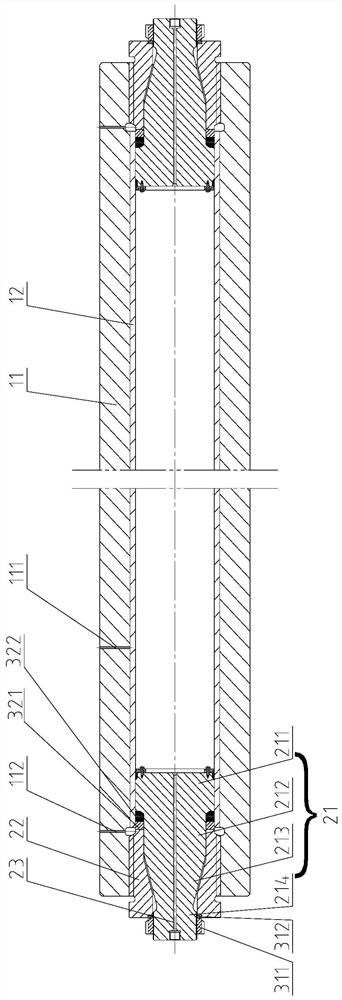

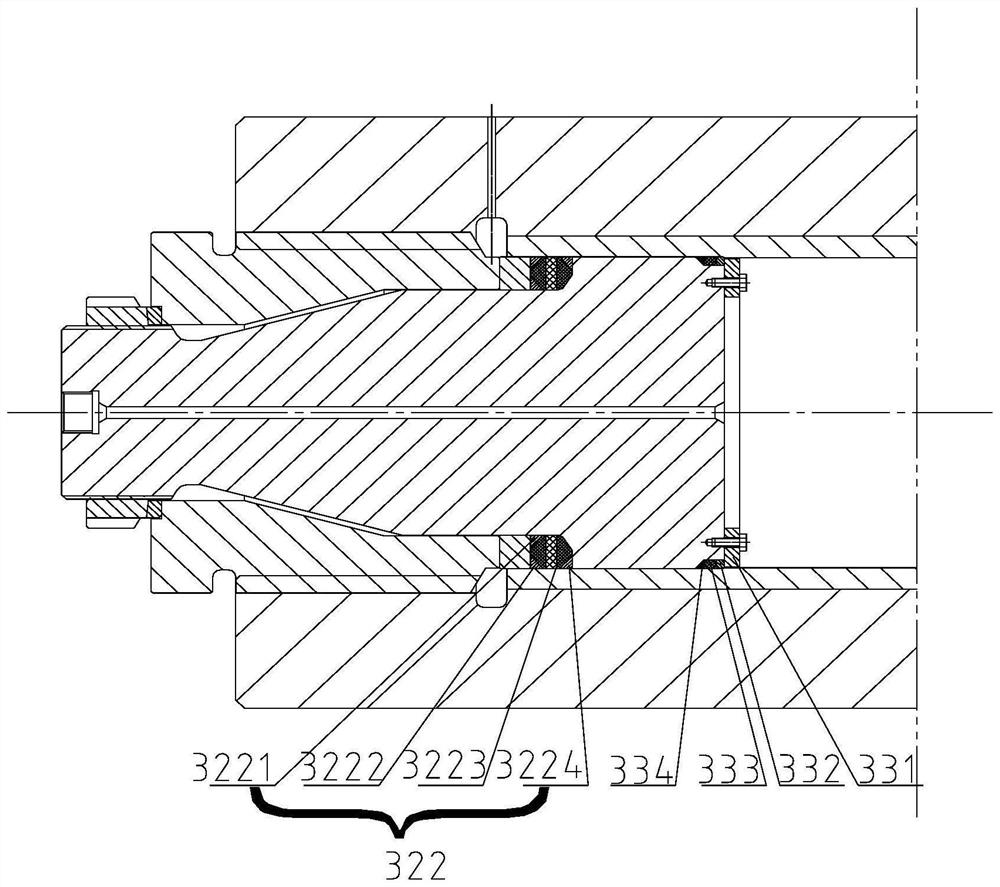

[0041] Such as figure 1 and figure 2 As shown, an ultra-high pressure hydrogen storage container includes a double-layer cylinder, a cover arranged on both sides of the cylinder, and a self-tightening sealing assembly for connecting the double-layer cylinder and the covers at both ends. The inner layer of the cylinder is used to suppress the penetration of hydrogen atoms, and the outer cylinder 11 is used to ensure the strength of the cylinder. In the self-tightening sealing assembly, leakage holes are opened on the outer cylinder 11 of the double-layer cylinder.

[0042] The outer cylinder body 11 and the inner cylinder body 12 of the double-layer cylinder body are fitted together by shrink fitting. The inner cylinder body 12 is made of high-alloy stainless steel, and its main function is to effectively inhibit the penetration of hydrogen atoms. The outer cylinder body 11 is a high-strength steel material or an ultra-high-strength steel material, and is an integral forging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com