Structure for reinforcing corroded concrete through prestress fiber reinforced composite sheet and reinforcing method

A fiber-reinforced composite and concrete structure technology, which is applied in bridge reinforcement, building components, building maintenance, etc., can solve the problems of impact on the service life of the structure performance, limit the application, and cannot slow down the corrosion rate of the main reinforcement in the structure to be reinforced, so as to achieve enhanced durability performance, improve the service life of the structure, and improve the effect of long-term reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

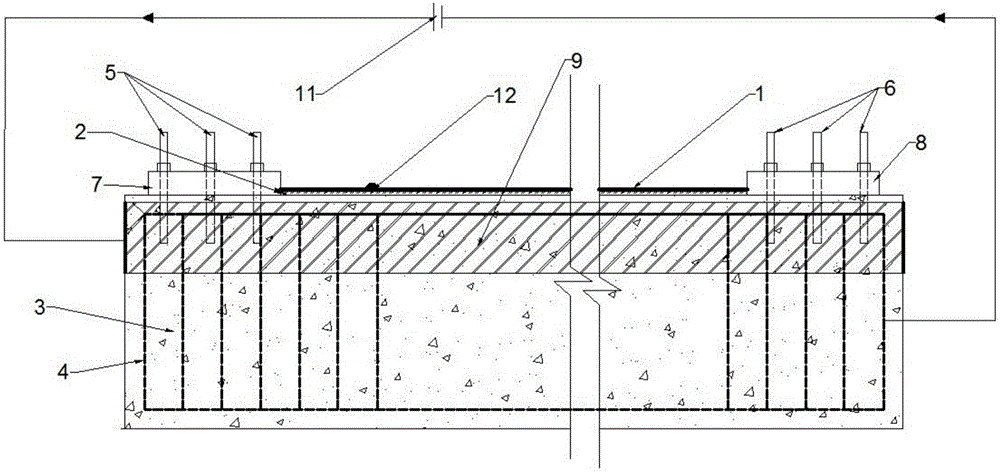

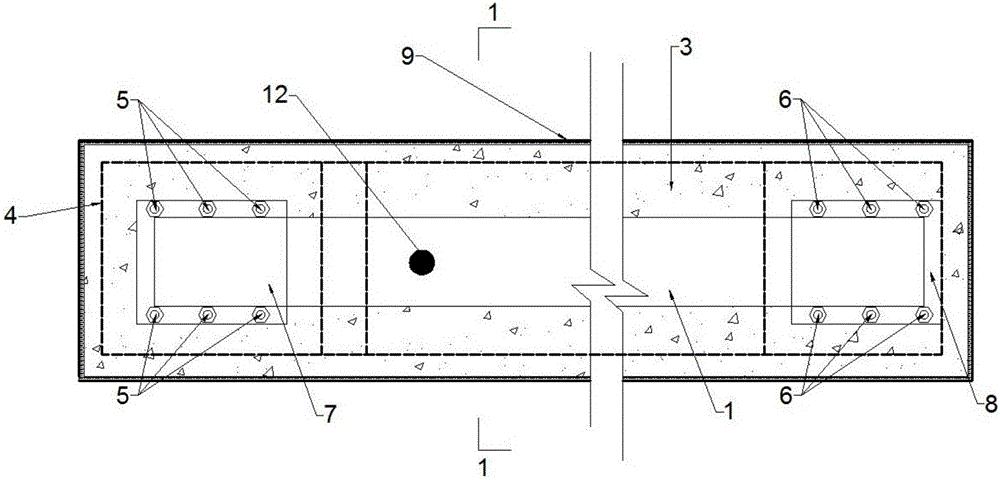

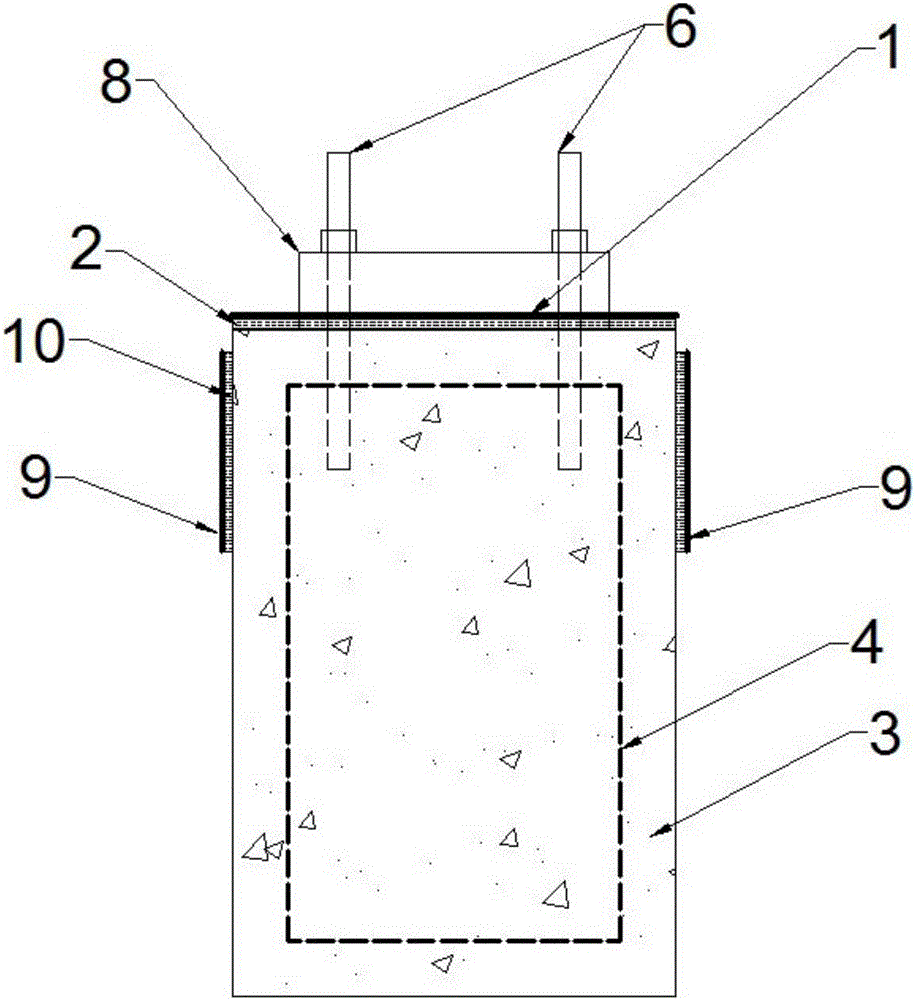

[0025] like Figure 1-3 As shown, the prestressed fiber-reinforced composite sheet strengthens the corroded concrete structure, including the concrete member to be reinforced (3), the prestressed fiber-reinforced composite sheet (1), the tension end anchor bolt (5), the tension end anchor Tool (7), fixed end anchor bolt (6), fixed end anchor (8), non-prestressed fiber reinforced composite sheet (9) and external intermittent constant current power supply (11); the tension end The anchors (7) and the fixed end anchors (8) respectively clamp the two ends of the prestressed fiber reinforced composite sheet (1) and fix the prestressed fiber reinforced composite sheet (1) on the The upper surface of the concrete member (3) to be reinforced; the inner reinforcement cage (4) is arranged inside the concrete member (3) to be reinforced, and the tension end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com