No-hydrogen atmosphere protection heat treatment process completely without decarburization for steel

An atmosphere and process technology, applied in the field of atmosphere protection of metal material heat treatment steel, can solve the problems of carbon loss, unsatisfactory decarburization protection, hardness and strength decline, etc., to achieve equipment investment cost reduction, considerable economic benefits, avoidance The effect of hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific implementation. The present invention was successfully tested for the first time on a large combined electric furnace of Xi'an Aircraft Manufacturing Company. Furnace volume is about 35M 3 , the main processing materials are 30CrMnSiA, 30CrMnSiNi2, 40CrNiMo, 4140 and other large aviation parts. The sample is a cylinder with a diameter of φ12 and a length of 10mm. The test has been carried out on the four materials mentioned above.

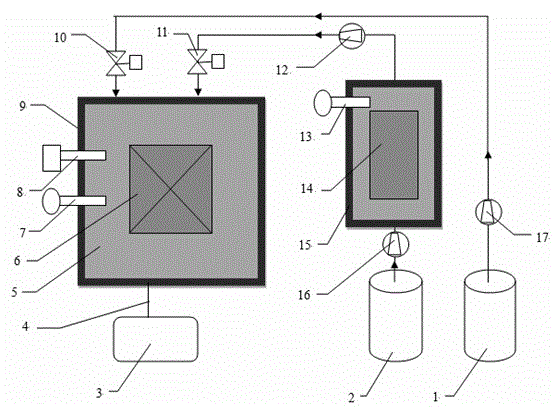

[0038] Such as figure 1 As shown, a completely decarburized hydrogen-free atmosphere protection heat treatment process for steel is implemented through the following steps:

[0039] 1) The raw materials are solid activated carbon (granular), CO 2 Gas and N 2 , the CO 2 and N 2 respectively stored in CO 2 In the storage device 2 and the nitrogen storage device 1, activated carbon is contained in the gas generator 15;

[0040] 2) Raw gas CO 2 from CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com