Process of preparing graphene coating on surface of metal

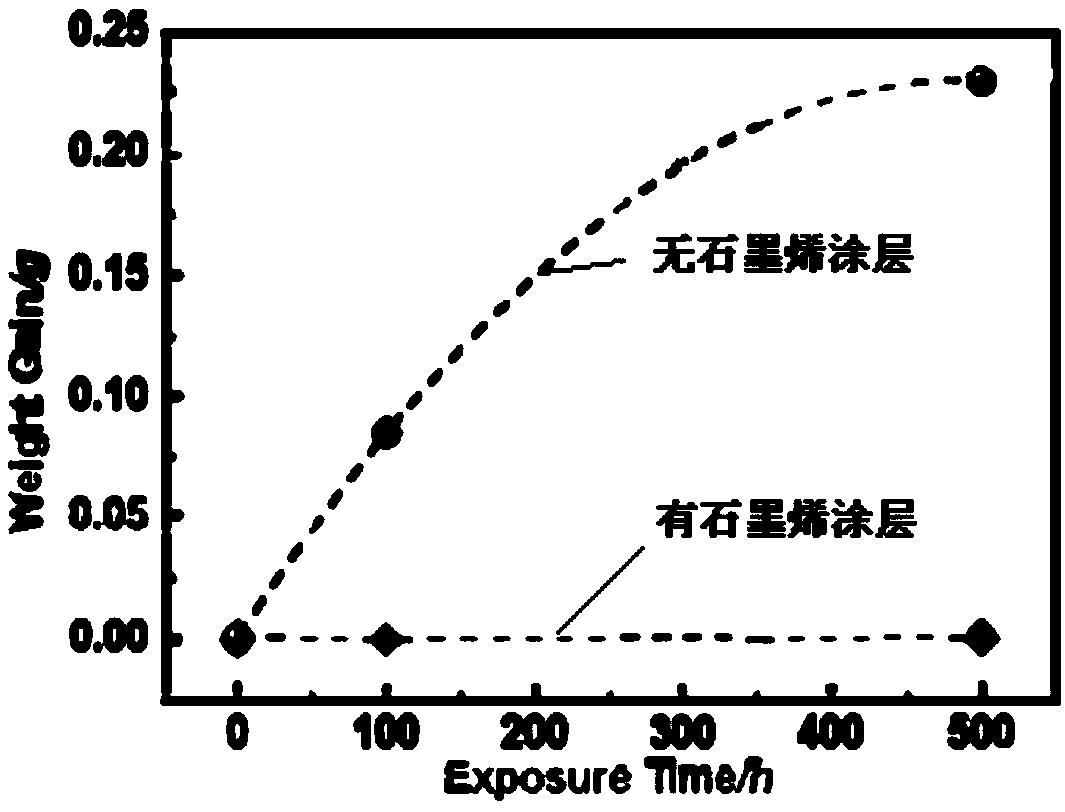

A metal surface and graphene technology, applied in the field of reactor engineering, can solve the problems of zirconium alloy hydrogen embrittlement, inconvenient operation, side reactions, etc., and achieve the effect of ensuring firmness, small thickness unevenness, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of technique that graphene coating is coated on metal surface, and this technique comprises the following several steps, and metal is zirconium alloy in the present embodiment, and shape is tubular:

[0037] (1) Metal surface pretreatment

[0038] Soak and ultrasonically clean the inner and outer surfaces of the metal with a solvent to remove surface impurities and oil stains; the solvent can be one or more of acetone, ethanol, deionized water, ultrapure water, and alkaline solution. The impurities and oil stains on the inner and outer surfaces of the metal can be removed by using the solvent, so that the graphene oxide can be better adsorbed on the inner and outer surfaces of the metal.

[0039] (2) The number of layers is 1 to 10 layers, and the graphene oxide aqueous solution with a mass fraction of 1.5 wt% soaks the metal sample described in step (1) for 20 minutes, so that the graphene oxide aqueous solution completely covers the inner and outer surfaces of ...

Embodiment 2

[0045] The difference from Example 1 is that the solvent in the step (1) is ethanol and potassium hydroxide solution, and the cleaning sequence is to soak in ethanol solution for 60 minutes, ultrasonic cleaning, and then soak in potassium hydroxide solution, ultrasonic Wash to remove surface oil and impurities. This step removes surface oil and impurities very thoroughly, ensuring successful coating of the graphene coating, and the unevenness of the coating thickness is less than 5%. The concentration of potassium hydroxide is 0.1mol / L. In the step (2), the number of layers selected is 20 to 50 layers, and the graphene oxide aqueous solution with a mass fraction of 10 wt% is sprayed on the metal sample; in the step (3), the drying temperature is 40° C., and the drying time is 72 hours , The dry environment is a low pressure protection environment of 0.05Pa. The reducing agent in step (4) is hydrazine, the microwave power range is 800W, the reducing temperature is 60°C, and t...

Embodiment 3

[0047]Different from Example 1, the solvent in the step (1) is ethanol and potassium hydroxide solution, and the cleaning sequence is to soak in ethanol solution for 40 minutes, ultrasonic cleaning, and then soak in potassium hydroxide solution, ultrasonic Wash to remove surface oil and impurities. The concentration of potassium hydroxide is 0.8mol / L. In the step (2), the graphene oxide aqueous solution with a mass fraction of 50 to 100 layers and a mass fraction of 0.1 wt% is selected for use in the step (2), and the metal sample is coated with a hanging brush; in the step (3), the drying temperature is 150° C., The drying time is 30 minutes, and the drying environment is air. In the step (4), the reducing agent is sodium hydrogen borate, and the reducing agent is ascorbic acid, hydrazine, sodium hydrogen borate or hydroiodic acid. The microwave power range is 1000W, the reduction temperature is 190 ° C, and the reduction time is 10 minutes; The cleaning agent is acetone. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com