Heat treatment method for austenite stainless steel wire

A technology of austenitic stainless steel and heat treatment method, which is applied in the direction of heat treatment furnace, heat treatment equipment, improvement of process efficiency, etc. It can solve the problems that steel wire cannot meet the ideal performance requirements and the annealing temperature is unreasonable, so as to improve the quality of steel wire and production Efficiency, optimized annealing temperature, effect of stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

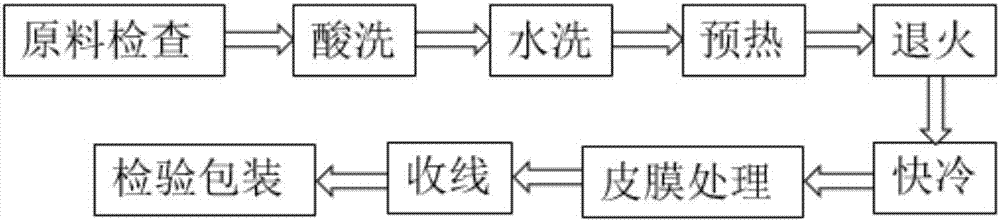

[0043] Austenitic stainless steel wire heat treatment process flow chart such as figure 1 As shown,

[0044] A heat treatment process for austenitic stainless steel wire, the process steps are as follows:

[0045] 1) Raw material inspection: check the surface for defects such as cracks, scratches, burrs, etc., and detect the ovality of the raw materials; detect the tensile strength and elongation of the raw materials;

[0046] 2) Pickling: The company uses sulfuric acid electrolytic pickling. Through the constantly changing current, the steel wire is electrolytically corroded, and gas is generated on the surface of the steel wire, thereby removing the impurities remaining on the surface of the steel wire, such as the surface film or lubricating powder;

[0047] 3) Water washing: rinse off the residual acid in the water washing section and blow dry;

[0048] 4) Preheating: Heat the washed and blow-dried steel wire to 450℃~500℃ and keep it for 3~5min. In addition to drying the steel wire,...

Embodiment 2

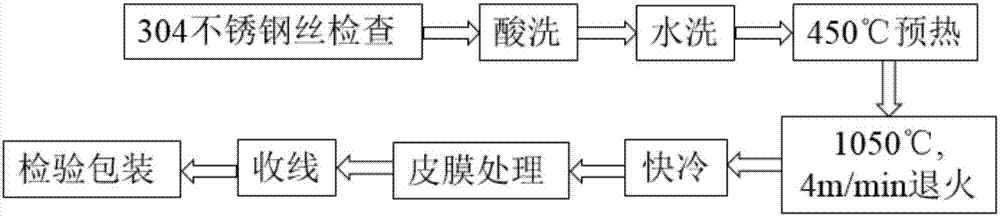

[0055] according to figure 2 The shown process heat treatment of 304 austenitic stainless steel after drawing hardening. First, check the hard wire of 304 austenitic stainless steel wire after drawing hardening, check whether the surface has defects such as cracks, scratches, burrs, etc., check the ovality of the raw material; detect the tensile strength and elongation of the raw material; Then, electrolytic pickling with sulfuric acid is used to make the steel wire electrolytically eroded through the constantly changing current, generating gas on the surface of the steel wire, thereby removing the impurities remaining on the surface of the steel wire, such as surface film or lubricating powder; after pickling, in the water washing section Rinse the residual acid solution in the blast furnace and blow dry; preheat the washed and blow-dried 304 austenitic stainless steel wire to 450℃ for 3min; send the preheated steel wire into the annealing furnace at 1050℃, It is 4m / min. In o...

Embodiment 3

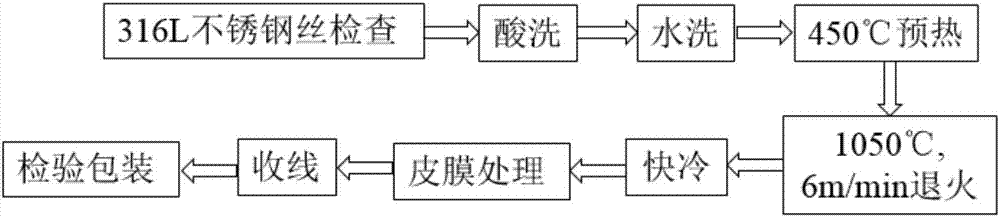

[0061] according to image 3 The shown process heats the 316L austenitic stainless steel wire after drawing hardening. First, inspect the hard wire of 316L austenitic stainless steel wire after drawing hardening to check whether the surface has defects such as cracks, scratches, burrs, etc., and inspect the ovality of the raw material; detect the tensile strength and elongation of the raw material; Then, electrolytic pickling with sulfuric acid is used to make the steel wire electrolytically eroded through the constantly changing current, generating gas on the surface of the steel wire, thereby removing the impurities remaining on the surface of the steel wire, such as surface film or lubricating powder; after pickling, in the water washing section Rinse the remaining acid solution in the blast furnace and blow dry; preheat the washed and blow-dried 316L austenitic stainless steel wire to 450°C for 3 minutes; send the preheated steel wire into the annealing furnace at 1050°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com