Tetraacetylethylenediamine (TAED) recrystallization method

A technology for crude tetraacetylethylenediamine and tetraacetylethylenediamine, which is applied in the separation/purification of carboxylic acid amides, organic chemistry, etc., can solve the problems of TAED hydrolysis and high toxicity, affecting product quality, low solubility, etc. Fast, easy recycling, high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

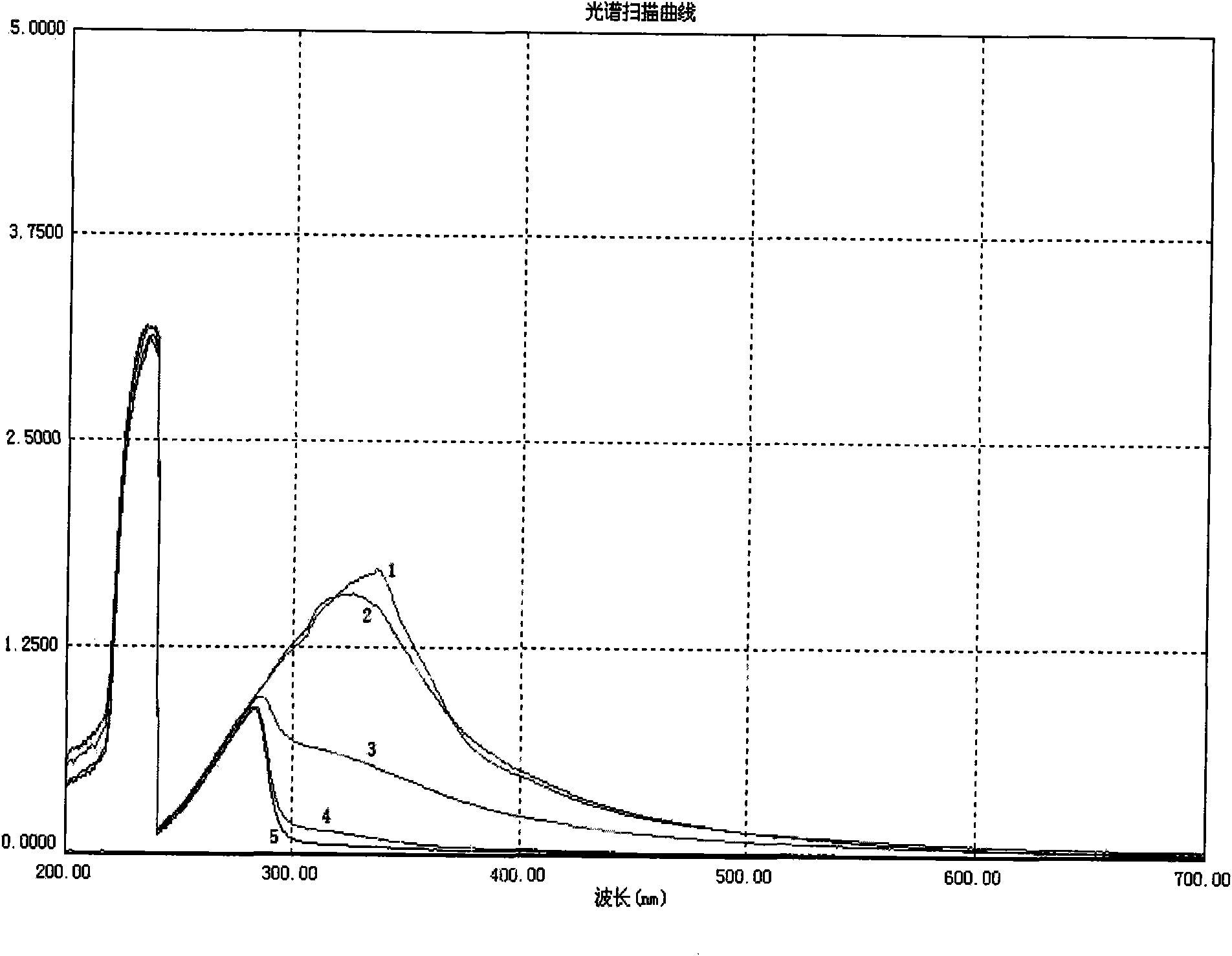

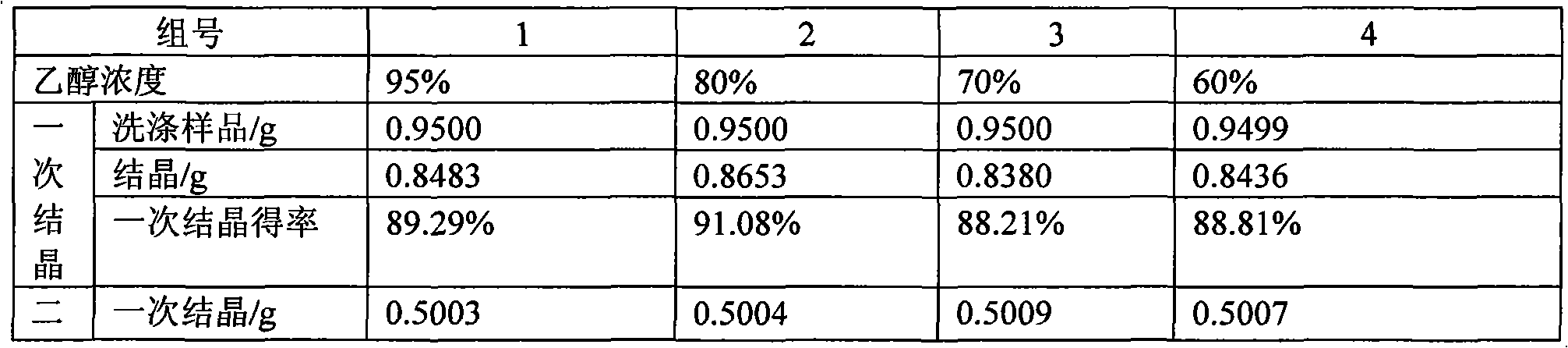

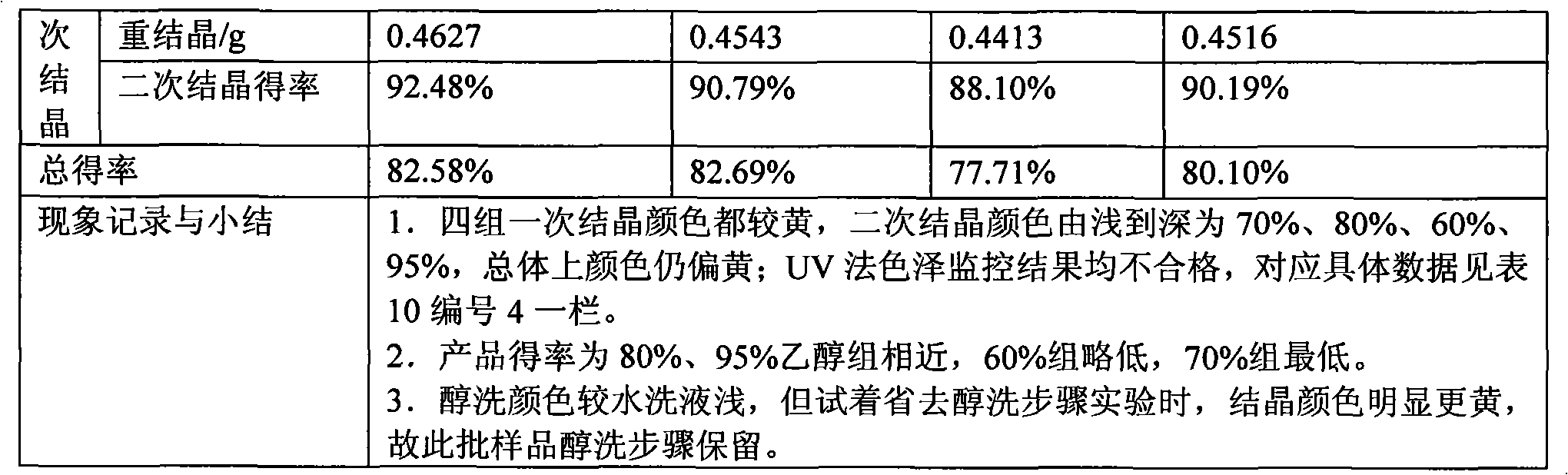

[0020] Hydroalcohol Concentration Selection:

[0021] Weigh four samples of about 1.0 g after washing, use 95%, 80%, 70%, and 60% of 10 times the amount of ethanol respectively, heat and reflux in a water bath at about 75°C for 25 minutes to completely dissolve the sample, take it out and let it cool and place it Complete crystallization in the refrigerator, filter, dry and weigh. Then weigh about 0.5 g of each sample obtained from the first recrystallization, and carry out the second recrystallization in the same way. See Table 1 for the corresponding conditions, results and precautions.

[0022] Table 1 Experimental results of water-containing alcohol concentration selection

[0023]

[0024]

Embodiment 2

[0025] Embodiment 2 mixed solvent proportioning test

[0026] According to the method of Example 1, the recrystallization test was carried out by mixing two solvents of dichloromethane and 80% ethanol, and the solvent ratios were (1:9), (2:8), (3:7), (4:6) ), the solvent consumption is 10 times, the operation steps are the same as above, and the results are shown in Table 2.

[0027] Table 2 dichloromethane and 80% ethanol mixed solvent proportioning test result

[0028]

Embodiment 3

[0029] The selection of ethanol concentration during mixed solvent recrystallization of embodiment 3

[0030] In view of the fact that 95% ethanol is relatively poor to the recrystallization decolorization effect of TAED in embodiment 1, the recrystallization yield of 70% ethanol is lower to TAED, and the mixed solvent recrystallization decolorization effect of embodiment 2 is better, so on this basis in In the range of 70% to 95%, the ethanol concentration is adjusted and selected again, that is, four concentration gradients of 90%, 85%, 80%, and 75% are selected to carry out the recrystallization experiment. The mixed solvent is composed of dichloromethane and water-containing alcohol in a ratio of (3:7), the amount of solvent is 10 times, the temperature of the water bath is 60 ° C (it can be boiled and quickly dissolved), the operation method is the same as above, and the results are shown in Table 3.

[0031] Table 3 The influence of ethanol concentration on the recrystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com