Dyeing promoter of acrylic fiber cationic dye and application thereof

A technology of cationic dyes and dyeing accelerators, which can be used in dyeing methods, textiles and papermaking, etc., can solve the problems of low dyeing rate of acrylic fiber dyeing at low temperature, and achieve improved dyeing rate, less damage to fiber strength, and good color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Fabric pre-treatment

[0030] Detergent 2092g / L, liquor ratio 1:50, at 60°C for 30min.

[0031] 2) Dyeing

[0032] Acrylic fiber 80-85 ℃ low temperature dyeing formula:

[0033] Cationic Dyes 1% (o.w.f)

[0034] Dye Accelerator 40ml / L

[0035] Acetic acid / sodium acetate to adjust the pH of the dye solution to about 5

[0036] Bath ratio 1:50

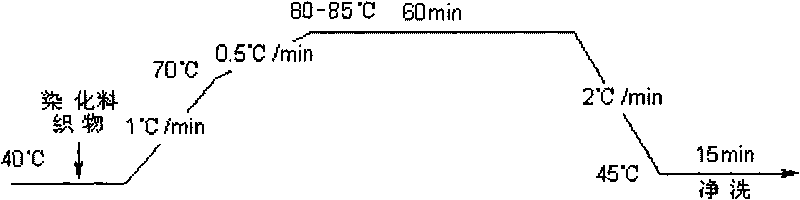

[0037] Acrylic fiber 80-85 ℃ low temperature dyeing process see attached figure 1 :

[0038] Formula for conventional dyeing of acrylic fiber at 98°C:

[0039] Cationic Dyes 1% (o.w.f)

[0040] 1227 1ml / L

[0041] Acetic acid / sodium acetate to adjust the pH of the dye solution to about 5

[0042] Bath ratio 1:50

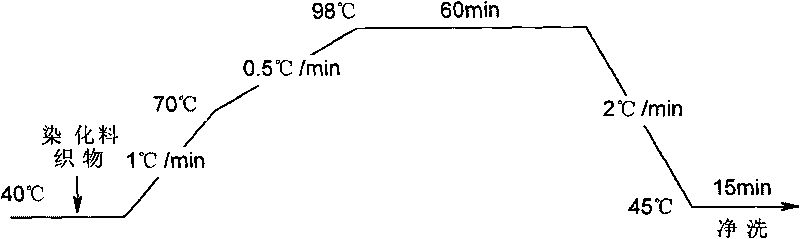

[0043] The conventional dyeing process of acrylic fiber at 98°C is attached figure 2 :

[0044] 3) wash

[0045] Cleaning agent 2092g / L, bath ratio 1:50, wash at 45°C for 15 minutes; wash with warm water.

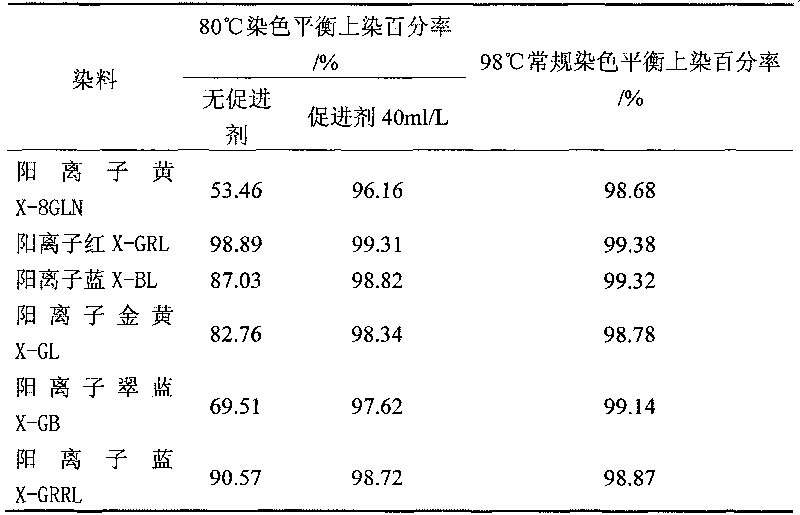

[0046] The following is the dyeing effect of acrylic fiber cationic dye balance dyeing percentage,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com