Cashmere dyeing process utilizing natural vegetable dyes and cashmere products

A plant dye, a natural technology, applied in dyeing, textiles and papermaking, dry-cleaning fiber products, etc., can solve the problems of poor color fastness, low dyeing rate, incomplete color spectrum, etc., to achieve improved color fastness, safe and comfortable wearing, The effect of increased color depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] A process for dyeing cashmere with natural vegetable dyes, comprising the following steps: cashmere yarn cleaning → cationic modification of cashmere fiber → neutralization → first soaping → dyeing → mordant dyeing → second soaping → oversoftening → dehydration → drying ; Described process parameter and prescription are as described in table 9.

[0149] Table 9 embodiment 1 natural plant dye cashmere dyeing process and prescription

[0150]

[0151]

[0152] Process step 1: pretreatment (cleaning of cashmere yarn)

[0153]

[0154] Pretreatment (cashmere yarn cleaning) steps:

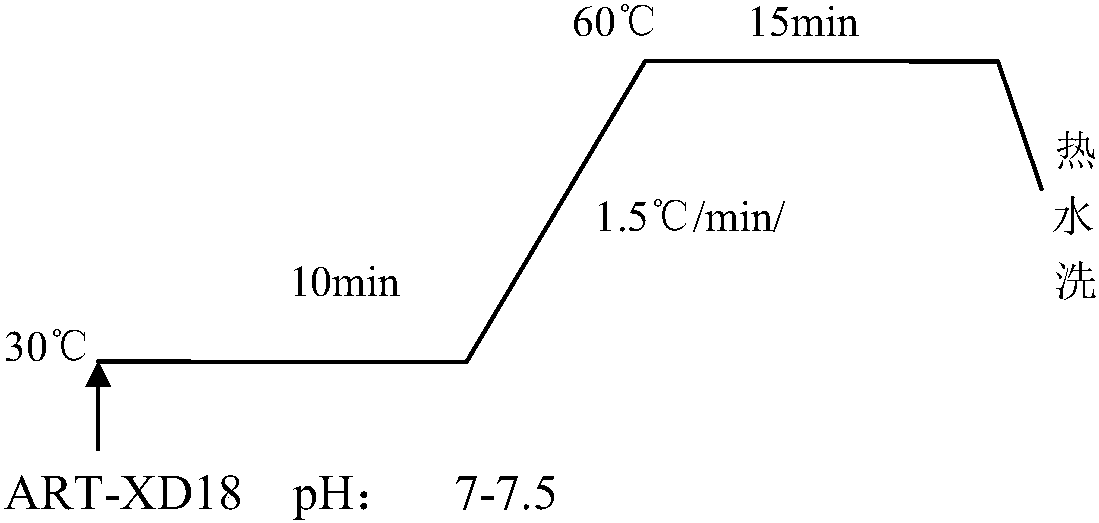

[0155]Carry out in the BELLINI LORIS skein dyeing machine (Bilini) machine, hang the skein, inject water, adjust the liquor ratio to 1:20, and maintain the pH at 7 to 7.5; add 1% cleaning agent ART-XD18, and heat up to 30 ℃, keep warm for 10min; 1.5℃ / min to 60℃, keep warm for 15min, and wash off the sundries.

[0156] Process Step 2: Cationic Modification

[0157]

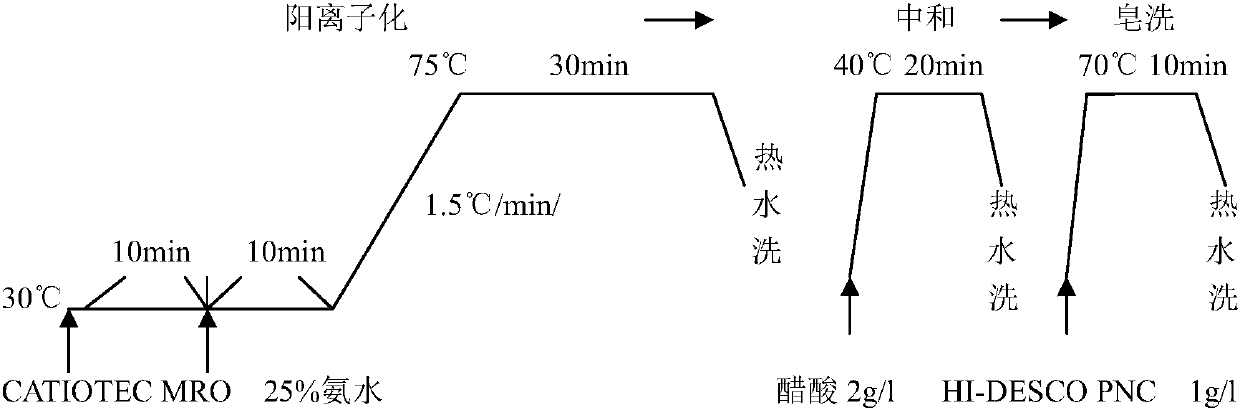

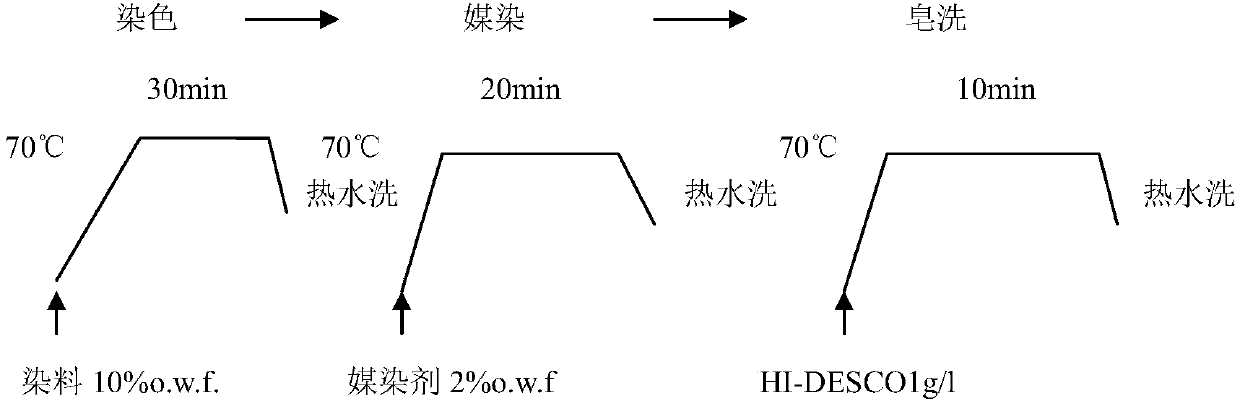

[0158] Cationi...

Embodiment 2

[0173] A process for dyeing cashmere with natural vegetable dyes, comprising the following steps: cashmere yarn cleaning → cationic modification of cashmere fiber → neutralization → first soaping → dyeing → mordant dyeing → second soaping → oversoftening → dehydration → drying ; Described processing parameter and prescription are as described in table 10.

[0174] Table 10 embodiment 2 natural plant dye cashmere dyeing process and prescription

[0175]

[0176] Process step 1: pretreatment (cleaning of cashmere yarn)

[0177]

[0178] Pretreatment (cashmere yarn cleaning) steps:

[0179] Carry out in the BELLINI LORIS skein dyeing machine (Bilini) machine, hang the skein, inject water, adjust the liquor ratio to 1:20, and maintain the pH at 7 to 7.5; add 1% cleaning agent ART-XD18, and heat up to 30 ℃, keep warm for 10min; 1.5℃ / min to 60℃, keep warm for 15min, and wash off the sundries.

[0180] Process Step 2: Cationic Modification

[0181]

[0182] Cationic modi...

Embodiment 3

[0197] A process for dyeing cashmere with natural vegetable dyes, comprising the following steps: cashmere yarn cleaning → cationic modification of cashmere fiber → neutralization → first soaping → dyeing → mordant dyeing → second soaping → oversoftening → dehydration → drying ; Described process parameter and prescription are as described in table 11.

[0198] Table 11 embodiment 3 natural vegetable dye cashmere dyeing process and prescription

[0199]

[0200] Process step 1: pretreatment (cleaning of cashmere yarn)

[0201]

[0202] Pretreatment (cashmere yarn cleaning) steps:

[0203] Carry out in the BELLINI LORIS skein dyeing machine (Bilini) machine, hang the skein, inject water, adjust the liquor ratio to 1:20, and maintain the pH at 7 to 7.5; add 1% cleaning agent ART-XD18, and heat up to 30 ℃, keep warm for 10min; 1.5℃ / min to 60℃, keep warm for 15min, and wash off the sundries.

[0204] Process Step 2: Cationic Modification

[0205]

[0206] Cationic mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com