Shrinkproof crease-resistant low strength loss flax fabric dyeing and finishing technique

A flax fabric and shrink-proof technology, applied in the field of dyeing and finishing, can solve the problems of insufficient liquid absorption of fabric fibers, lack of anti-shrinkage and anti-wrinkle strength, low production efficiency, etc. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

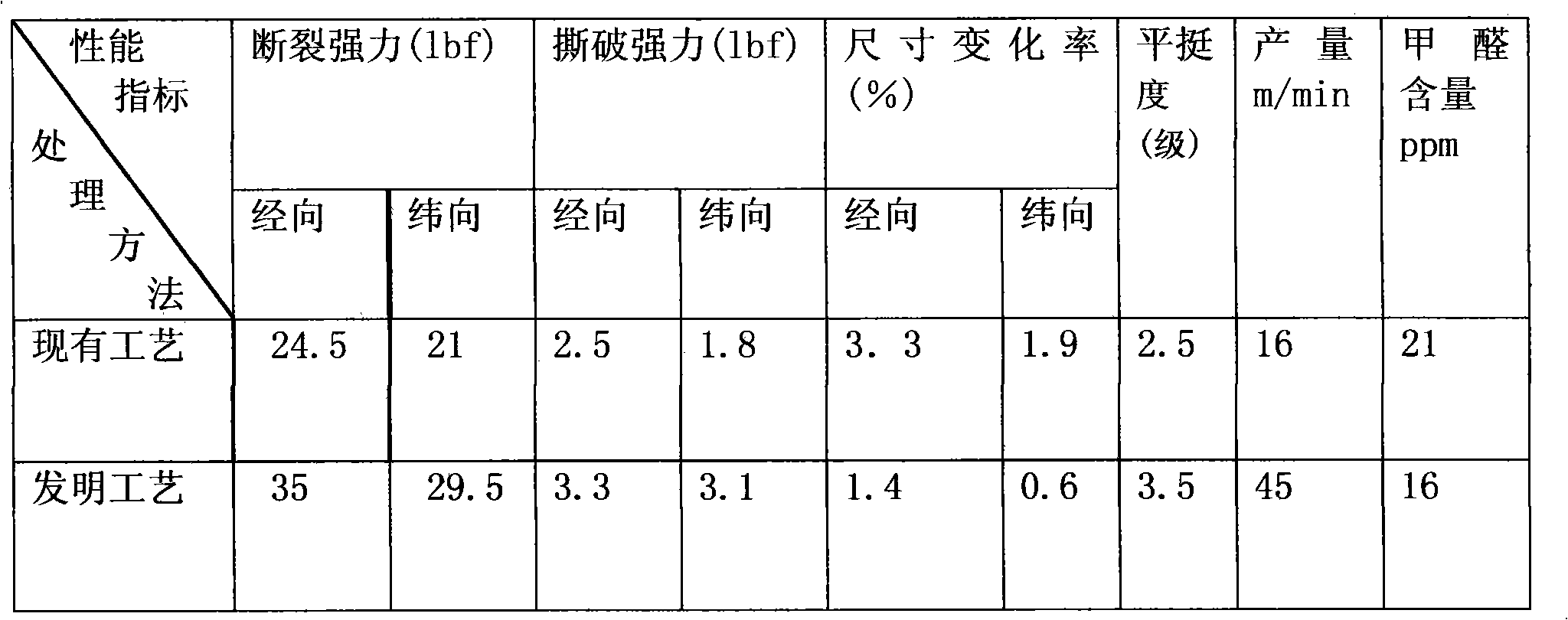

[0013] Example 1: Now the yarn count is 14×14, the specification is 54×54, and the gram weight is 170g / m 2 Linen fabrics as an example.

[0014] The dyeing and finishing process of linen fabrics with anti-shrinkage, anti-wrinkle and low strength loss includes the steps of second-dipping and second-rolling finishing working liquid of linen fabrics after dyeing, high-temperature baking, washing, drying and pre-shrinking, specifically:

[0015] 1. Padding finishing working solution

[0016] In order to ensure the full penetration of the finishing working solution, the fabric adopts the second padding and finishing working solution step on the setting machine. According to the weight and strength of the cloth, the excess rate of the first padding and finishing working solution is 95%, and the pressure of the first pressing roller is 95%. 1.5Kg, the speed of the shaping machine is 55 m / min.

[0017] The resin cross-linking agent is preferably F-ECO resin cross-linking agent produ...

Embodiment 2

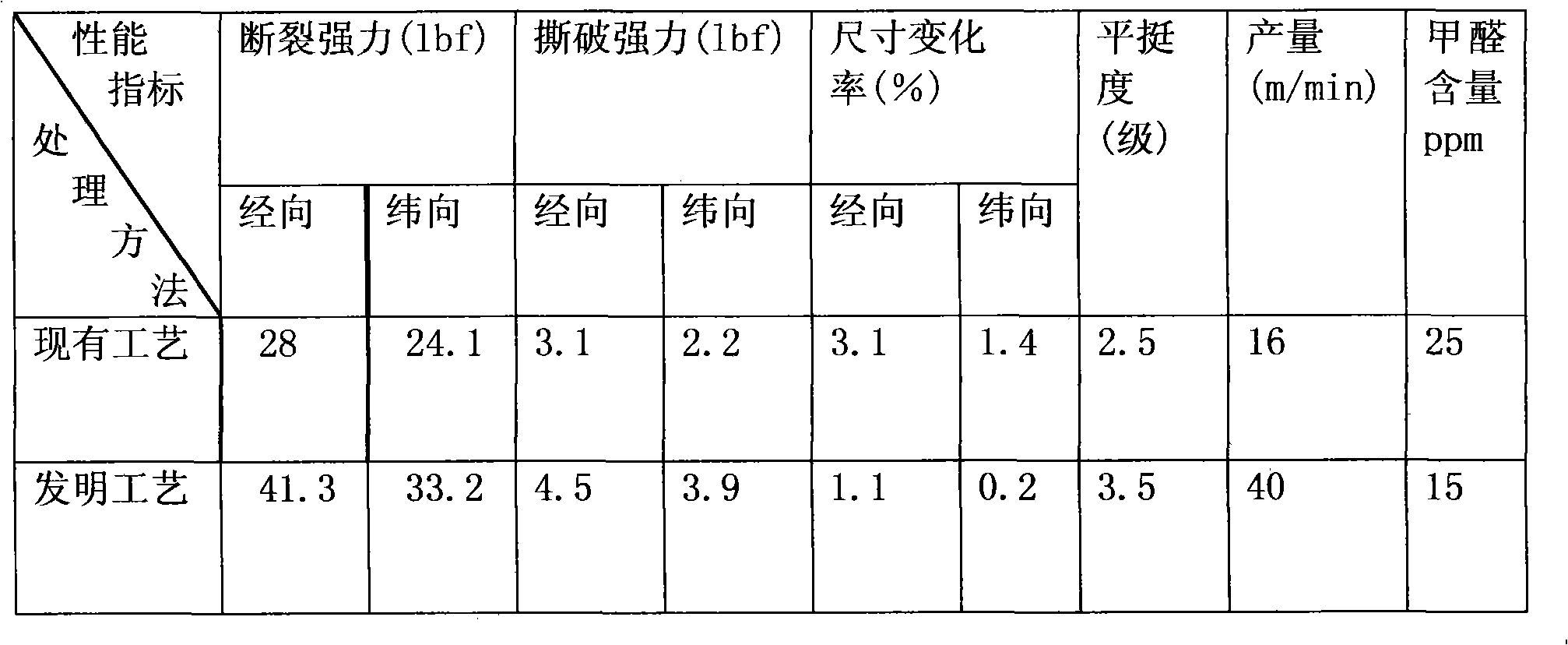

[0031] Example 2: Yarn count 12×12, specification 48×48, gram weight 225g / m 2 linen fabric.

[0032] Process step is the same as embodiment 1, according to cloth weight and strong force, difference is that the pressure of the first roller is 1.6Kg, the pressure of the second roller is 1.9Kg, and the speed of the shaping machine is 50 meters per minute.

[0033] According to the cloth weight and strength, the formula of the finishing working liquid used in the second padding step is: BASF F-ECO resin crosslinking agent is 80g / L, Tuona USV water-soluble polyurethane strong protective agent is 35g / L , BASF F-M catalyst is 20g / L, Taifeng T80A modified silicone softener is 40g / L, and the rest is water.

[0034] 12×12, 48×48, gram weight 225g / m produced according to the above process 2 The linen products, after 3 times of washing, the test data are as follows:

[0035]

Embodiment 3

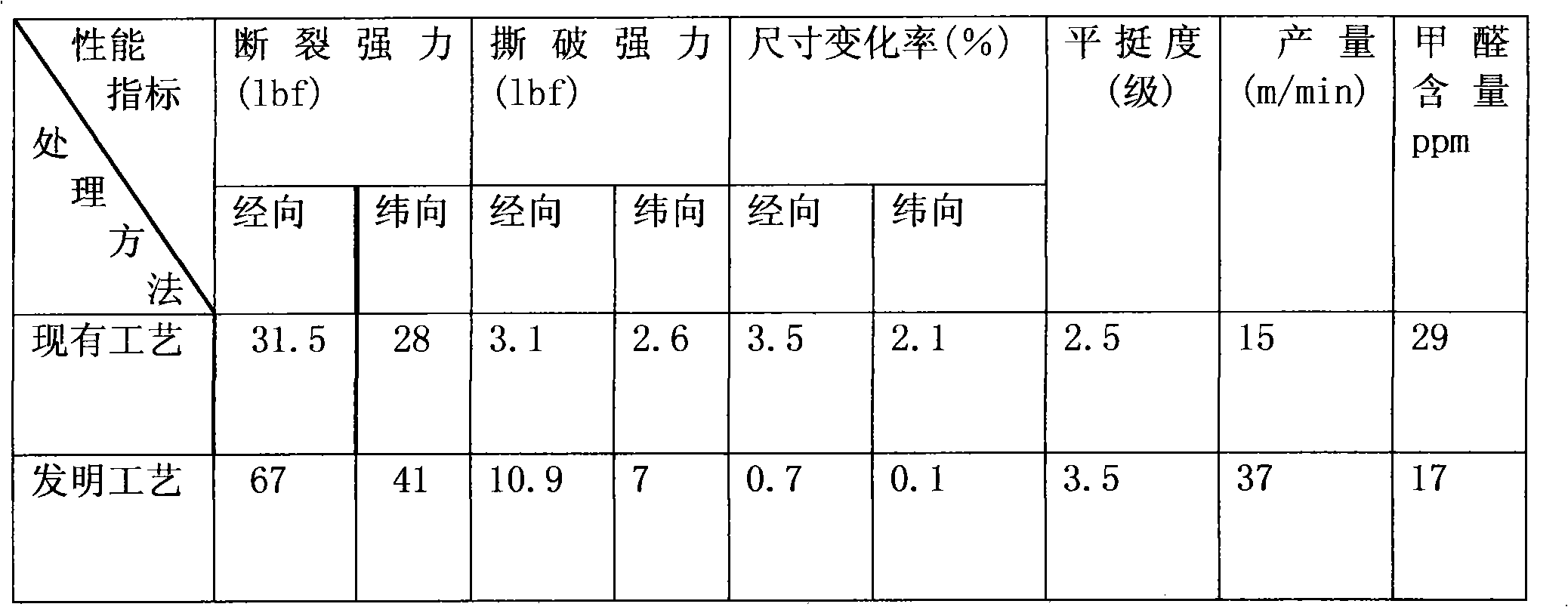

[0036] Embodiment 3: Yarn count 9×9, specification 42×42, gram weight 260g / m 2 linen fabric.

[0037] Process step is the same as embodiment 1, according to cloth weight and strong force, difference is that the pressure of the first press roller is 1.7Kg, the pressure of the second press roller is 2.0Kg, and the speed of the sizing machine is 40 meters per minute.

[0038] According to the cloth weight and strength, the formula of the finishing working liquid used in the second padding step is: BASF F-ECO resin crosslinking agent is 100g / L, Tuona USV water-soluble polyurethane strong protective agent is 40g / L , BASF F-M catalyst is 25g / L, Taifeng T80A modified silicone softener is 50g / L, and the rest is water.

[0039] 9×9, 42×42 produced according to the above process, and the weight is 260g / m 2 The linen products, after 3 times of washing, the test data are as follows:

[0040]

[0041] The data in the above three tables show that:

[0042] The linen fabric treated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com