Dyeing and finishing treatment method for all-cotton suede-like broad width fabric

A processing method and fabric technology, applied in fabric surface trimming, textile and paper making, roughening, etc., can solve the problems of fabrics such as easy shedding, uneven strength, and easy pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

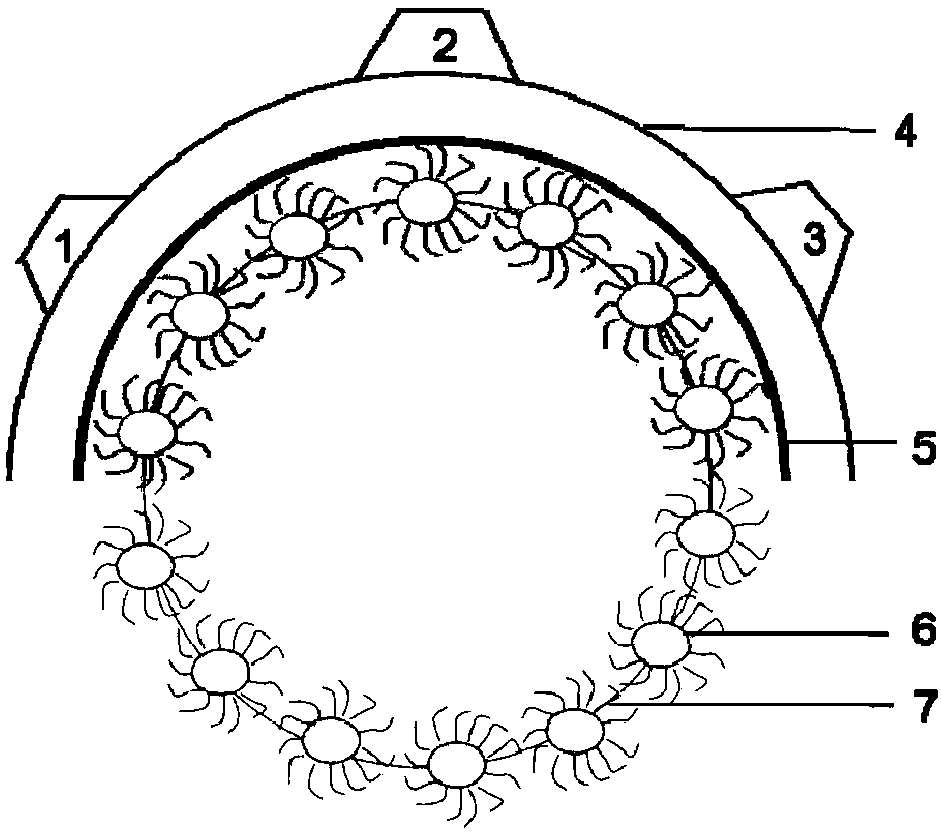

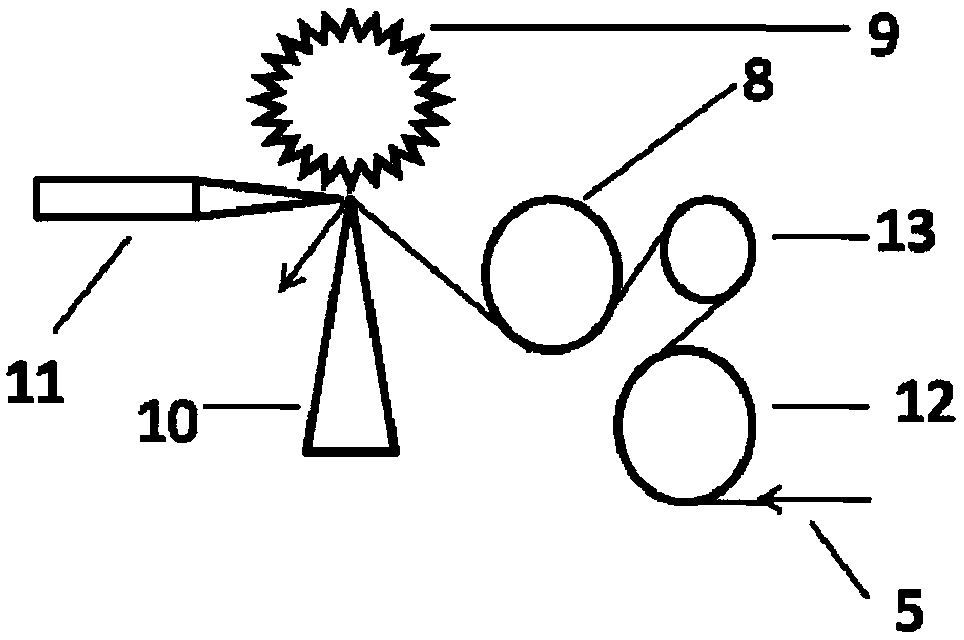

Image

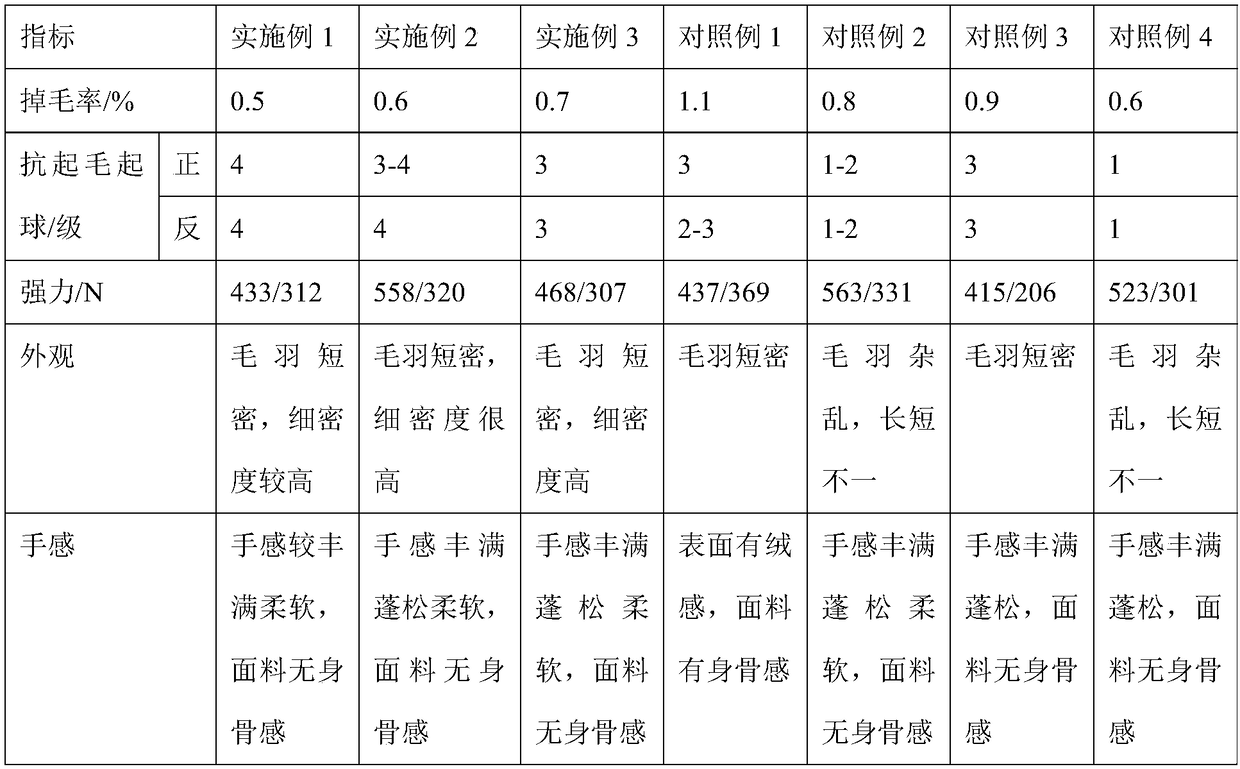

Examples

Embodiment 1

[0021] Fabric specification: 105” / 40s / 2*40s / 2 / 78*68, two up and two down left slant, dyed yarn, pink.

[0022] The fabric undergoes singeing, desizing, napping, shearing and softening processes in sequence.

[0023] Singeing: one positive and one negative light singeing, the speed is 90-100 m / min.

[0024] Desizing: Enzyme desizing, stacking at 50-60°C for 6 hours, and then washing with hot water for 5 times.

[0025] Stenter: speed 30m / min, raising agent 40g / L, temperature 140°C.

[0026] Pulling:

[0027] (1) Front napping: negative pressure suction volume 165m 3 / h, vacuum degree -300mbar, expanding roll speed is 300 rpm, cylinder speed is 90 rpm, cloth feeding speed is 30 m / min; clockwise roller speed is 400 rpm, clockwise roll pressure -0.2 Mpa; the speed of the anti-knitting roller is 600 rpm, the pressure of the anti-knitting roller is 0.3Mpa; the tension of the cloth guide roller is 2.5%;

[0028] (2) Napping on the reverse side: the rotating speed of the expandin...

Embodiment 2

[0036] Fabric specification: 105” / 32s / 2*32s / 2 / 90*65, two up and two down left oblique, printed fabric.

[0037] The fabric is sequentially singed, deboiled and bleached, stretched and whitened, napped, sheared, printed, steamed and washed, and softened.

[0038] Cold stacking of singeing and enzyme rolling: gas singeing, vehicle speed 110m / min, one front and one reverse, medium burning, enzyme rolling to extinguish the fire, pile up for 4-6h.

[0039] Scouring: Using a combined cooking and bleaching machine, stacked in double layers. Process conditions: NaOH 40g / L, refining agent 12g / L, penetrant 5g / L, steaming at 102℃*60min, speed 80m / min.

[0040] Bleaching: impregnation working liquid hydrogen peroxide 3g / L, pH9.5, penetrating agent 4g / L, chelating dispersant 4g / L, scouring enzyme 25g / L, steam at 100℃*40min, speed 80m / min.

[0041] Stenter whitening: speed 30m / min, raising agent 40g / L, temperature 140°C.

[0042] Pulling:

[0043] (1) Front napping: negative pressure su...

Embodiment 3

[0053] Fabric specification: 105” / 21s*16s / 83*68, two up and two down left slant, dyed sky blue.

[0054] The fabric goes through singeing, descouring and bleaching, tentering, mercerizing, tentering (with raising agent), napping, shearing, dyeing and softening in sequence.

[0055] Cold stacking of singeing and enzyme rolling: gas singeing, vehicle speed 110m / min, one front and one reverse, medium burning, enzyme rolling to extinguish the fire, pile up for 4-6h.

[0056] Scouring: Using a combined cooking and bleaching machine, stacked in double layers. Process conditions: NaOH 40g / L, refining agent 12g / L, penetrant 5g / L, steaming at 102℃*60min, speed 80m / min.

[0057] Bleaching: impregnation working liquid hydrogen peroxide 3g / L, pH9.5, penetrating agent 4g / L, chelating dispersant 4g / L, scouring enzyme 25g / L, steam at 100℃*40min, speed 80m / min.

[0058] Stenter drying: temperature 140°C, speed 40m / min. The door width is pulled to 263-265cm.

[0059] Mercerizing: Alkali so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com