Scouring enzyme, and preparation method, application and application method thereof

A technology of scouring enzyme and pectin compound enzyme is applied in the field of textile printing and dyeing cotton and polyester-cotton pretreatment auxiliaries, which can solve the problems of unsatisfactory quality stability, large fiber damage and short stacking time. The effect of improving color rate and levelness, reducing damage and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

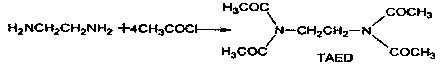

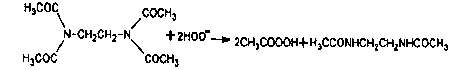

[0040] The scouring enzyme in this embodiment is made from the following raw materials: 6% nonionic surfactant, 35% soda ash, 8% alkaline pectin complex enzyme, peroxide hydrogen peroxide activator (tetraacetylethylenediamine TAED and sodium percarbonate quality 6%, NTA 4% and anhydrous sodium metasilicate 41%.

[0041] Its preparation method is:

[0042] First mix 6% of nonionic surfactant and 35% of soda ash evenly, then add 8% of alkaline pectin compound enzyme and mix evenly, then add peroxide hydrogen peroxide activator (tetraacetylethylenediamine TAED and sodium percarbonate quality (1:2 compound) 6%, NTA (sodium nitrogen triacetate) 4%, mix evenly, finally add 41% sodium metasilicate pentahydrate, mix evenly, stir for about 1 hour, and make white small particles The powder, namely the refined enzyme product, is named A203.

Embodiment 2

[0044] The scouring enzyme in this embodiment is made from the following raw materials: 9% nonionic surfactant, 48% soda ash, 3% alkaline pectin compound enzyme, peroxide hydrogen peroxide activator (tetraacetylethylenediamine TAED and sodium percarbonate quality 5%, NTA 3% and anhydrous sodium metasilicate 32%.

[0045] Its preparation method is:

[0046] First mix 9% of non-ionic surfactant and 48% of soda ash evenly, then add 3% of alkaline pectin compound enzyme and mix evenly, then add peroxide hydrogen peroxide activator (tetraacetylethylenediamine TAED and sodium percarbonate quality (1:2 compound) 5%, NTA (sodium nitrilotriacetate) 3%, mix evenly, finally add zero-water sodium metasilicate 32%, mix evenly, stir for about 1 hour, and make white small particles Powder, that is, refined enzyme finished product.

Embodiment 3

[0048] The scouring enzyme in this embodiment is made from the following raw materials: 7% nonionic surfactant, 25% soda ash, 9% alkaline pectin complex enzyme, peroxide hydrogen peroxide activator (tetraacetylethylenediamine TAED and sodium percarbonate quality 4%, NTA 5% and anhydrous sodium metasilicate 50%.

[0049] Its preparation method is consistent with the method of Example 1, only the ratio of raw materials is changed.

[0050]

[0051] The using method of scouring enzyme of the present invention is as follows:

[0052]The dosage varies with fiber types and processing conditions. Example 4: One-bath scouring and bleaching of cotton, polyester / cotton knitted fabrics Hydrogen peroxide (27%) 5-7g / L The scouring enzyme A203 prepared in Example 1 2-3g / L Liquor ratio 1: 7-10, 70℃~85 ℃, 50-60 minutes, wash with hot water and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gross effect | aaaaa | aaaaa |

| Gross effect | aaaaa | aaaaa |

| Gross effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com