Progressive axial flow scutcher

A kind of cotton cleaning machine, progressive technology, applied in the direction of cleaning and cleaning machine, fiber cleaning machine, etc., can solve the problems of limited effect of removing fine impurities, large distance between dust removal knives, difficult to remove fine impurities, etc., to avoid repetition Strike, good effect, good effect of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

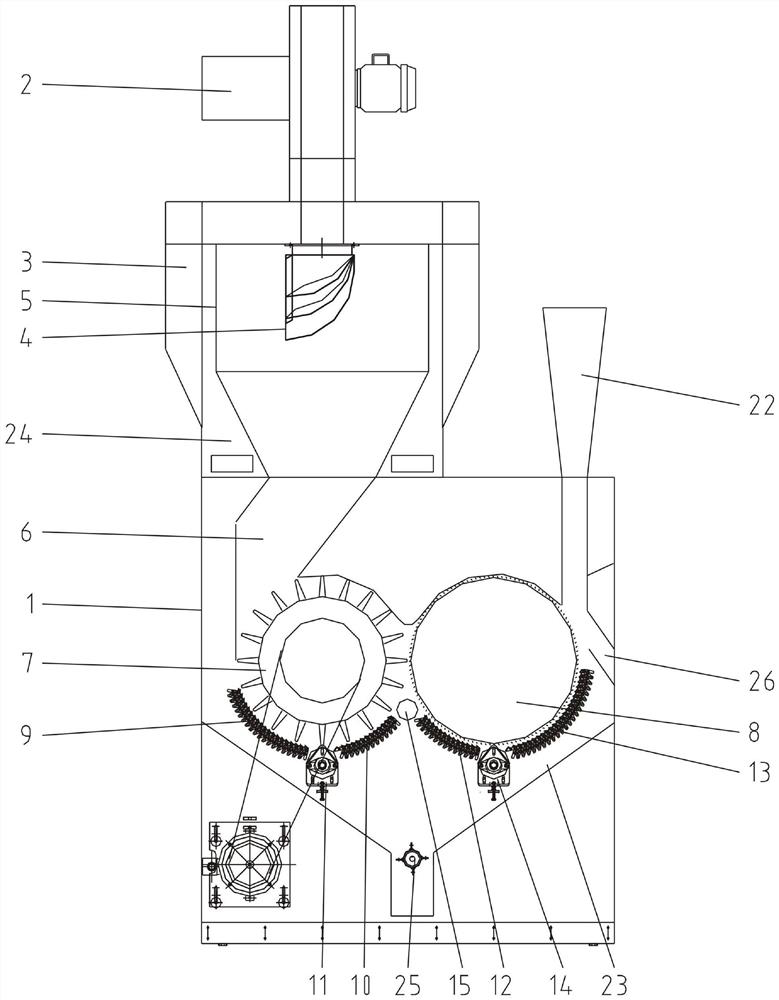

[0037] Such as figure 1 As shown, a progressive axial flow cotton cleaning machine of the present invention includes a casing 1, the top of the casing 1 is provided with a cotton collection inlet 2, and the cotton collection inlet 2 is provided with a strong force for sucking cotton into the casing 1 In the dust collector 3, a rotating spout 4 is provided at the position where the cotton collecting inlet 2 is connected with the inner cavity of the casing 1, and the rotating spout 4 is surrounded by a large dust cage 5 fixed inside the casing 1, and the large dust cage 5 The bottom outlet is connected to the cleaning machine assembly located at the lower part of the inner cavity of the casing 1 .

[0038]In the present invention, by setting the rotating spout 4, the cotton can be rotated 360° while spraying down, and at the same time, the outer ring of the rotating spout 4 surrounds the large dust cage 5. This design is the first, and the cotton can be diffused and rotated duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com