Anti-bacterial-adhesion conductive hydrogel and preparation method and application thereof

A conductive hydrogel and reactant technology, applied in pharmaceutical formulations, bandages, drug delivery, etc., can solve problems such as wound infection or immune response, human health threat, inflammatory response, etc., to increase stability and environmental adaptability, The effect of high water content and good processing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) A solution of silver nitrate (0.1mM, 97mL), sodium citrate (180mm, 1mL), polyvinylpyrrolidone (4.2mM, 1mL) and hydrogen peroxide (30wt.%, 0.24mL) was mixed and heated at room temperature Stir vigorously under the open lid. Sodium borohydride (100 mm, 0.30 mL) was then quickly added to the above mixed solution. After reacting for 30 minutes, a blue colloidal solution of silver nanoparticles in a triangular shape was obtained.

[0022] (2) 95 mg of dopamine was dissolved in the above-prepared silver nanoparticle aqueous solution. The pH of the system was adjusted to 8.5 by adding NaOH solution (1 M) dropwise, and vigorously stirred at room temperature for 2 hours to obtain dopamine-coated silver nanoparticles.

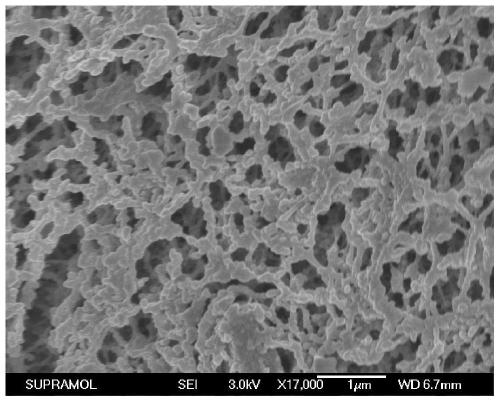

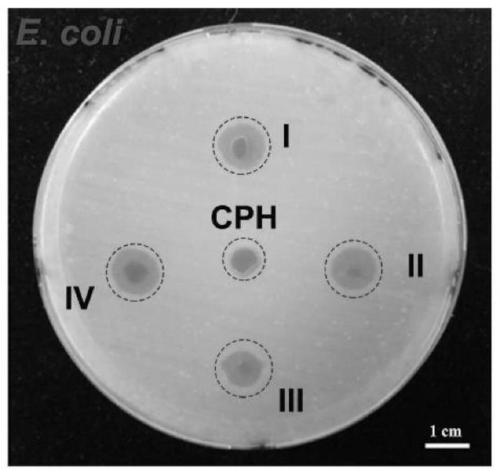

[0023] (3) Preparation of antibacterial adhesive conductive hydrogel. Take 9 mL of the dopamine-coated silver nanoparticle solution prepared above, add 1 g of polyvinyl alcohol, and stir at 90° C. until completely dissolved. Then 200 μL of aniline, 75 mg o...

Embodiment 2

[0025] (1) A solution of silver nitrate (0.1mM, 97mL), sodium citrate (180mm, 1mL), polyvinylpyrrolidone (4.2mM, 1mL) and hydrogen peroxide (30wt.%, 0.24mL) was mixed and heated at room temperature Stir vigorously under the open lid. Sodium borohydride (100 mm, 0.30 mL) was then quickly added to the above mixed solution. After reacting for 30 minutes, a blue colloidal solution of silver nanoparticles in a triangular shape was obtained.

[0026] (2) 95 mg of tannic acid was dissolved in the silver nanoparticle aqueous solution prepared above. The pH of the system was adjusted to 8.5 by adding NaOH solution (1 M) dropwise, and vigorously stirred at room temperature for 2 hours to obtain silver nanoparticles coated with tannic acid.

[0027] (3) Preparation of antibacterial adhesive conductive hydrogel. Take 9 mL of the tannic acid-coated silver nanoparticle solution prepared above, add 1 g of agar, and stir at 90° C. until completely dissolved. Then 200 μL of aniline, 75 mg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com