Metal ion cross-linked hydrogel as well as preparation method and application thereof

A technology for cross-linking hydrogels and metal ions, applied in gel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problem of uncontrollable release of metal ions, complex hydrogel preparation methods, and suitable metal ion cross-linking systems. narrow range and other problems, to achieve the effects of controllable gel time, good prospects for large-scale production, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of metal ion cross-linked hydrogel of the present invention, comprises the following steps:

[0026] (1) Use the carbodiimide method to graft small organic molecules containing hydrazide groups on water-soluble polymers containing carboxyl groups, react at room temperature for 12 to 36 hours, and then go through dialysis-freeze-drying process or non-solvent precipitation process , to obtain a hydrazide polymer with a modification degree of 5% to 80%;

[0027] (2) Mixing the hydrazidated polymer aqueous solution and the metal ion solution evenly to obtain the metal ion cross-linked hydrogel.

[0028] The used reagent of the carbodiimide method described in step (1) is 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide, 1- The amount of (3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride is 1 to 1.2 times the molar number of carboxyl groups to be modified in the carboxyl-containing water-soluble polymer...

Embodiment 1

[0039]Sodium hyaluronate with a molecular weight of 200kDa is made into a solution with a mass percentage concentration of 1%; then, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide with a degree of modification of 1 times is added Hydrochloride and 1.1 times N-hydroxysuccinimide, followed by 3,3'-dithiodipropionylhydrazide with 10 times the number of hydrazide groups to be modified; at pH 5.0 After reacting at room temperature for 24 hours, use a dialysis bag with a molecular weight cut-off of 1000Da to dialyze water for 10 hours, and then freeze-dry at minus 20 degrees Celsius for 24 hours to obtain hydrazide hyaluronic acid with a modification degree of 20%. Finally, hydrazide The hyaluronic acid is made into an aqueous solution with a mass concentration of 3%, and is uniformly mixed with the calcium chloride solution to obtain a calcium ion cross-linked hyaluronic acid hydrogel, wherein the mass percentage concentration of the calcium ion is 0.1%.

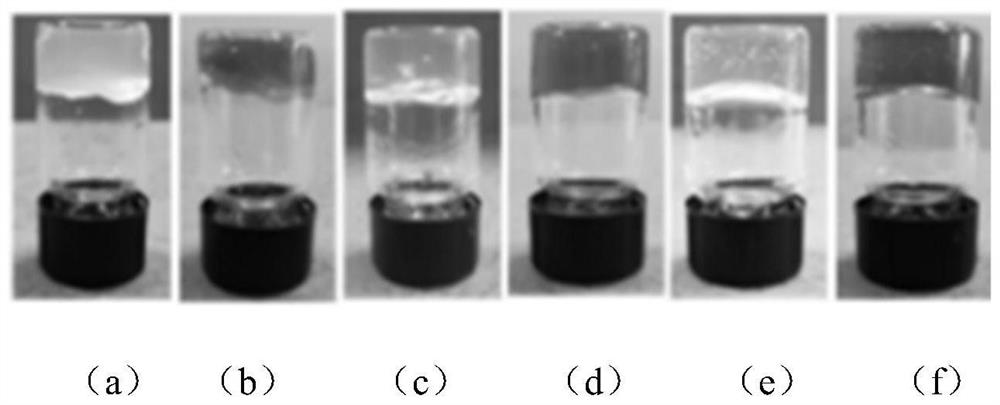

[0040] The photo of the hy...

Embodiment 2

[0042] Sodium hyaluronate with a molecular weight of 200kDa is made into a solution with a mass percentage concentration of 1%; then, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide with a degree of modification of 1 times is added Hydrochloride and 1.1 times N-hydroxysuccinimide, followed by 3,3'-dithiodipropionylhydrazide with 10 times the number of hydrazide groups to be modified; at pH 5.0 After reacting at room temperature for 24 hours, use a dialysis bag with a molecular weight cut-off of 1000Da to dialyze water for 10 hours, and then freeze-dry at minus 20 degrees Celsius for 24 hours to obtain hydrazide hyaluronic acid with a modification degree of 20%. Finally, hydrazide The hyaluronic acid is made into an aqueous solution with a mass concentration of 3%, and is uniformly mixed with the silver nitrate solution to obtain a silver ion cross-linked hyaluronic acid hydrogel, wherein the mass percentage concentration of the silver ion is 0.2%.

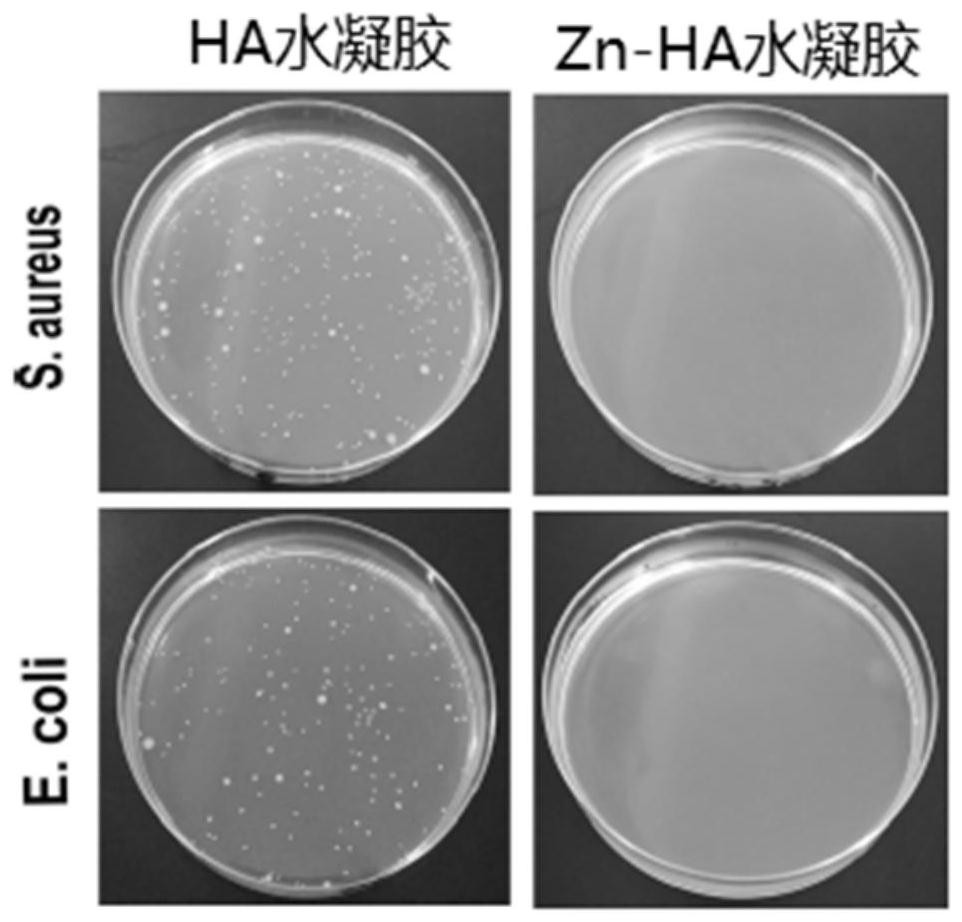

[0043] The photo of the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com