Nano hybrid silk fibroin hydrogel and preparation method and application thereof

A technology for silk fibroin and regenerated silk fibroin, applied in the field of nano-hybrid silk fibroin hydrogel and its preparation, can solve the problem of unfavorable cell or biological factor viability, ranging from a few days to a few weeks, gel Avoiding the use of chemical cross-linking agents, good vigor, and rapid gelation without problems such as long curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

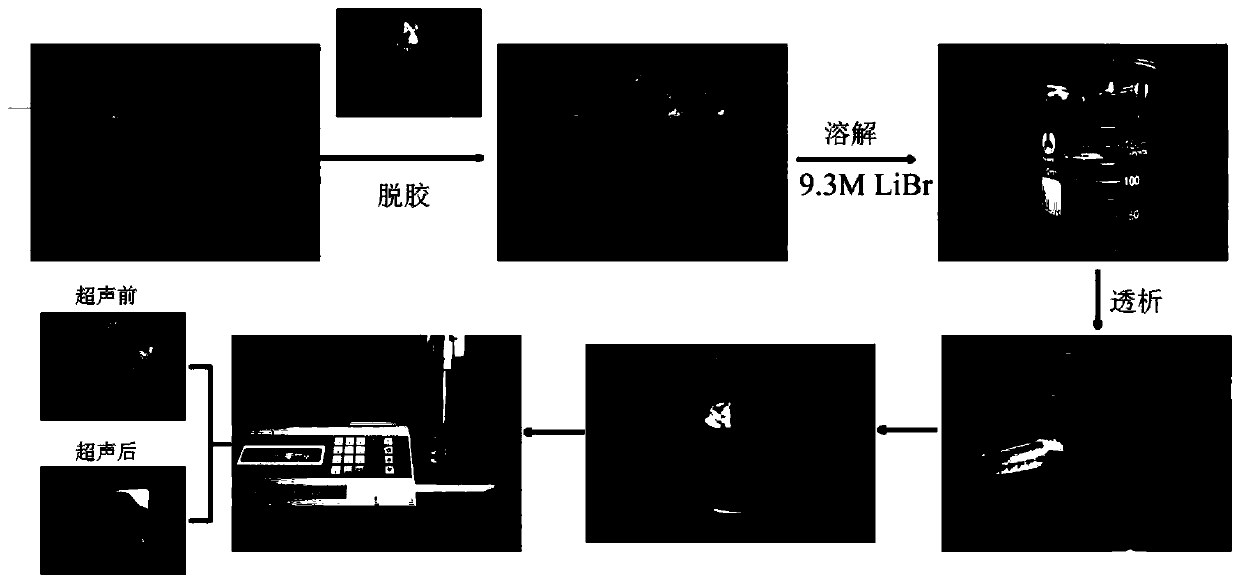

[0069] A kind of preparation method of nanoscale hydroxyapatite hybrid silk fibroin hydrogel, such as figure 2 shown, including the following steps:

[0070] (1) According to the bath ratio of 1:50 (mass ratio), add silkworm cocoons into 0.02M sodium carbonate solution and boil for 30 minutes, repeat twice, wash with pure water several times, tear loose, and dry at 40°C. Weigh the dried silk protein at a concentration of 15% by mass fraction, dissolve it at 60°C for 2 hours with a LiBr solution with a concentration of 9.3M, then put it into a dialysis bag with a molecular weight cut-off of 3500, and dialyze it with pure water at 4°C for three days. During this period, the water was changed every 6 hours, and the insoluble precipitate was removed by gauze filtration to obtain an aqueous solution of regenerated silk fibroin; it was stored in a refrigerator at 4°C.

[0071] (2) Disperse the nano-sized hydroxyapatite in the pure aqueous solution according to the concentration of...

Embodiment 2

[0078] A preparation method of nano-hybrid silk fibroin hydrogel for bone defect repair, such as figure 2 shown, including the following steps:

[0079] (1) According to the bath ratio of 1:50 (mass ratio), add silkworm cocoons into 0.02M sodium carbonate solution and boil for 30min, repeat twice, wash with pure water several times, and dry at 40°C; The 9.3M LiBr solution was dissolved at 60°C for 1 hour, so that the mass fraction of silk protein in the dissolved mixed solution was 15%, and then put into a dialysis bag with a molecular weight cut-off of 3500, and dialyzed in pure water at 10°C for three days. The polyethylene glycol solution (molecular weight is 20,000 Da) of %wt concentrates the regenerated silk fibroin aqueous solution after dialysis into the regenerated silk fibroin aqueous solution of 6%wt (determined by dry weighing method), removes insoluble precipitate by gauze filtration, Store in refrigerator at 4°C.

[0080] (2) Disperse nano-sized hydroxyapatite ...

Embodiment 3

[0085] A preparation method of nano-hybrid silk fibroin hydrogel for bone defect repair, such as figure 2 shown, including the following steps:

[0086] (1) According to the bath ratio of 1:50 (mass ratio), add silkworm cocoons into 0.02M sodium carbonate solution and boil for 30min, repeat twice, wash with pure water several times, and dry at 40°C; The 9.3M LiBr solution was dissolved at 60°C for 1 hour, so that the mass fraction of silk protein in the dissolved mixed solution was 15%, and then put into a dialysis bag with a molecular weight cut-off of 3500, and dialyzed in pure water at 10°C for three days. %wt polyethylene glycol solution (molecular weight: 20,000 Da) to concentrate the dialyzed regenerated silk fibroin aqueous solution into a 6%wt regenerated silk fibroin aqueous solution, filter through gauze to remove insoluble precipitates, and store in a refrigerator at 4°C.

[0087] (2) Disperse nano-sized hydroxyapatite in pure aqueous solution according to the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com