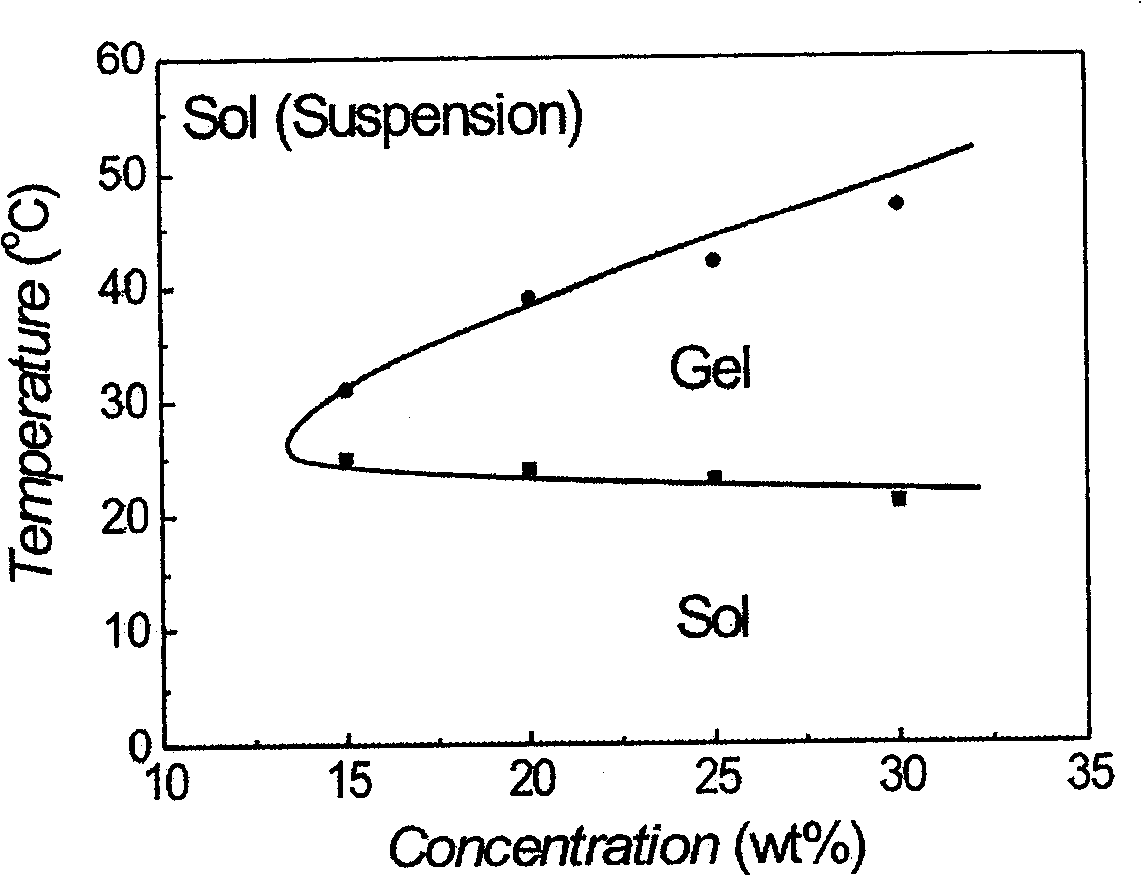

Degradable temperature sensitive physical aquagel and its preparation method

A hydrogel and temperature inversion technology, which is applied in the direction of medical preparations of non-active ingredients, drug delivery, and pharmaceutical formulations, can solve the problems of toxicity, non-degradability, and inability to achieve long-term drug delivery, and achieve good water absorption and operation Simple and convenient, the effect of mature reaction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 10g of polyethylene glycol (1500) into a 250ml three-necked flask, then add 15.6g of DL-lactide and 3.13g of glycolide, heat it under vacuum to make it melt completely, add 20mg of stannous isooctanoate, and heat up the oil bath Reaction at 160°C for 24 hours. After the reaction is completed, the initial product is dissolved in dichloromethane solution, and methanol is precipitated. The yield is about 85%. Then, under an argon atmosphere, add 10 g of block copolymer to a 250 ml three-necked flask, dissolve 100 ml of dichloromethane solution, add anhydrous pyridine equimolar to acetyl chloride, and stir evenly; Add 30 ml of a mixed solution of acetyl chloride (the molar ratio of the same block copolymer is 4 / 1) and methylene chloride dropwise, and the addition is completed within a few hours; remove the ice-water bath and continue the reaction at room temperature for 8 hours. Finally, it is filtered and precipitated with a large amount of anhydrous methanol to obtai...

Embodiment 2

[0033] Add 10g of polyethylene glycol (1000) to a 250ml three-necked flask, then add 10.22g of DL-lactide and 4.84g of glycolide, heat it under vacuum to melt it completely, add 20mg of stannous isooctanoate, and heat up the oil bath Reaction at 160°C for 24 hours. After the reaction was completed, the initial product was dissolved in dichloromethane solution, and methanol was precipitated. The yield was about 81%. Then, under an argon atmosphere, add 10 g of block copolymer to a 250 ml three-necked flask, dissolve 100 ml of dichloromethane solution, add anhydrous pyridine equimolar to propionyl chloride, and stir evenly; Add 30 ml of a mixed solution of propionyl chloride (the molar ratio of the same block copolymer is 4 / 1) and methylene chloride dropwise, and the addition is completed within a few hours; remove the ice-water bath and continue the reaction at room temperature for 8 hours. Finally, it is filtered and precipitated with a large amount of anhydrous methanol to o...

Embodiment 3

[0035] Add 10g single-ended methoxypolyethylene glycol (5000) in a 250ml three-necked flask, then add ε-caprolactone 18.94g, after heating under vacuum to make it melt completely, add 20mg of stannous isooctanoate, and the oil bath is heated up to React at 160°C for 24 hours. After the reaction is completed, the initial product is dissolved in dichloromethane solution, and methanol is precipitated. The yield is about 82%. Then under argon atmosphere, in 250ml there-necked flask, add the block copolymer of 10g, after 100ml dichloromethane solution dissolves, add equimolar succinic anhydride and anhydrous pyridine (with block copolymer mol ratio is 4 / 1), reflux for 12 hours; after the reaction is completed, filter, add a large amount of anhydrous methanol for precipitation, and obtain a carboxyl-terminated block copolymer derivative with a yield of about 80%. pass 1 H-NMR and 13 C-NMR measures the relative molecular weight of copolymer composition and block; Measures the num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com