SiC nanoparticle and SiC whisker hybrid toughened ZrC-based superhigh temperature ceramic composite material and preparation method thereof

An ultra-high temperature ceramic and nanoparticle technology, which is applied in the field of ultra-high temperature ceramic composite materials and their preparation, can solve the problems of low density and high cost of ZrC-based ultra-high temperature ceramics, reduce pore defects, reduce price, and improve strength and toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

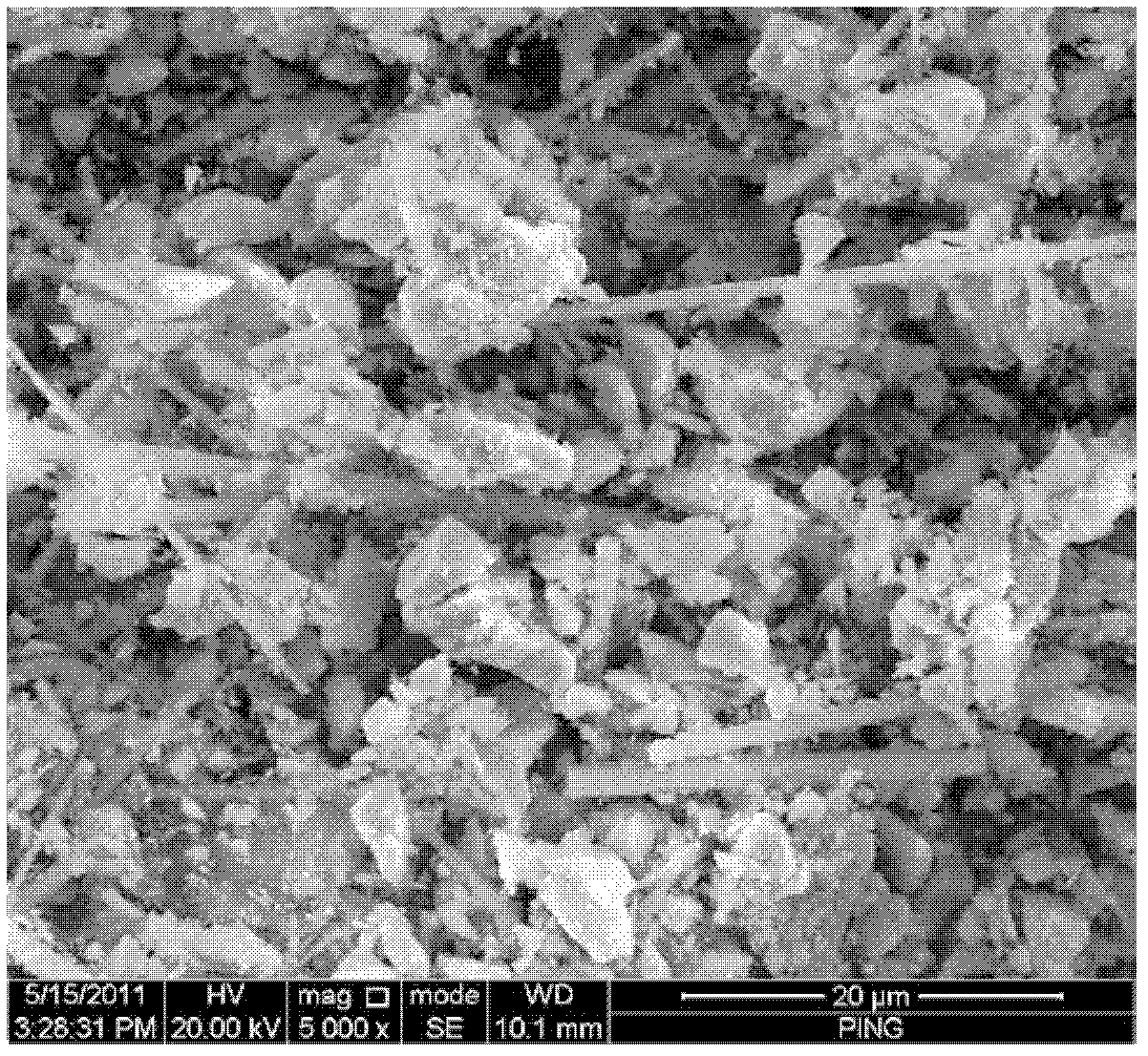

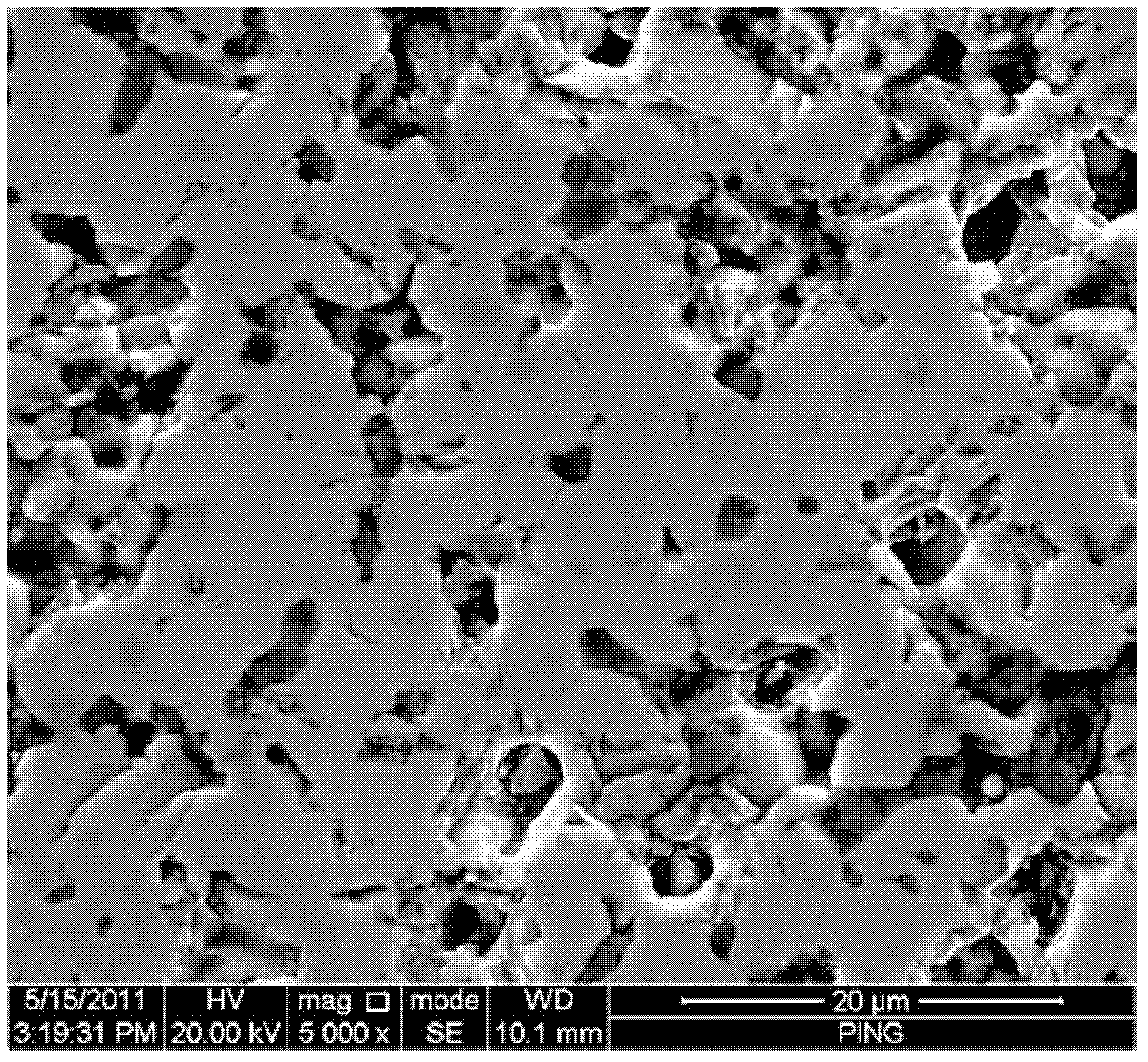

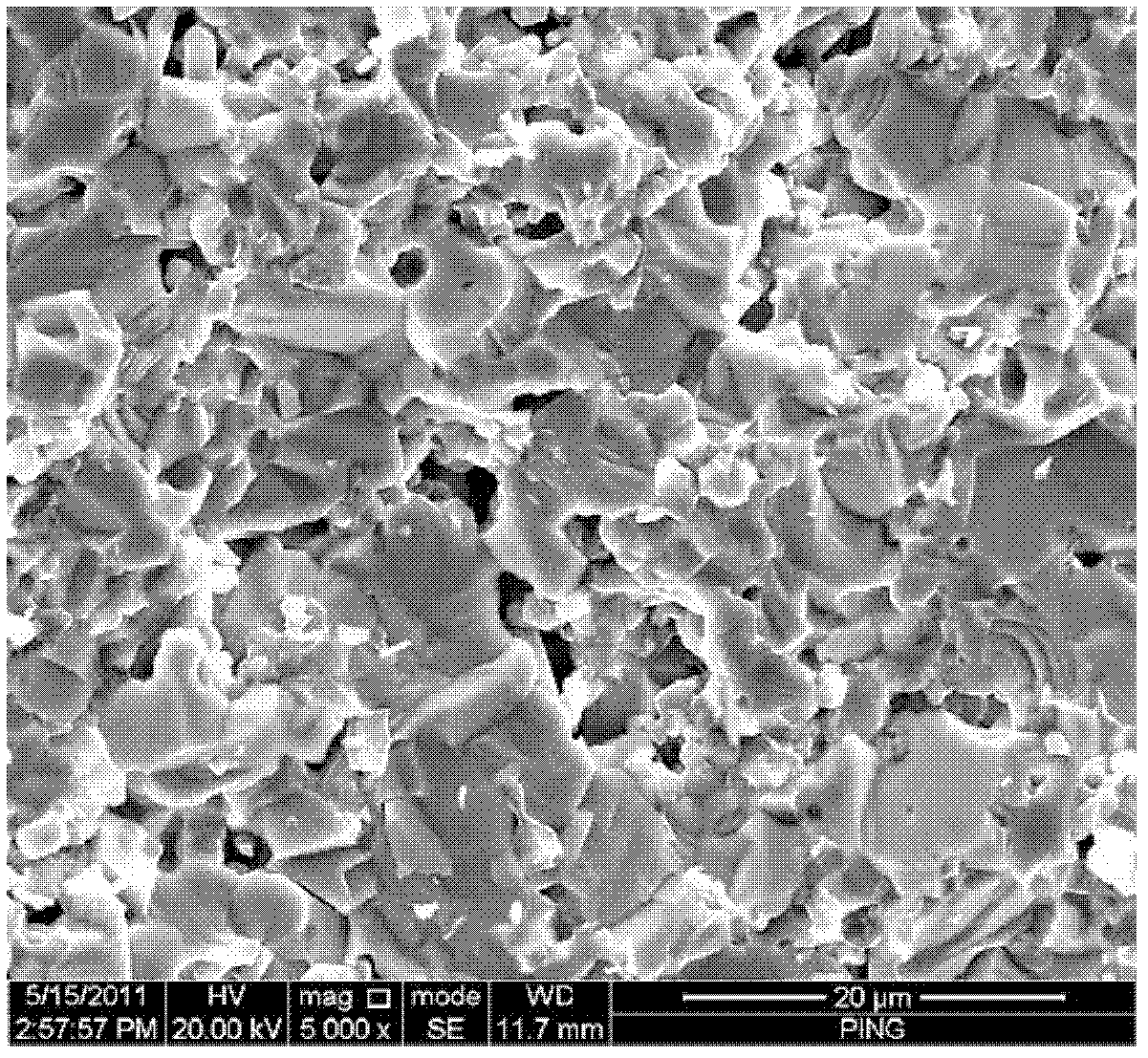

[0009] Specific embodiment 1: The hybrid toughened ZrC-based ultra-high temperature ceramic composite material of SiC nanoparticles and SiC whiskers of this embodiment is made of SiC nanoparticles, SiC whiskers and a ZrC matrix; SiC nanoparticles and SiC whiskers are used as reinforcing phases In the ZrC matrix, the volume percentage of SiC nanoparticles is 5% to 15%, the volume percentage of SiC whiskers is 5% to 15%, and the volume percentage of ZrC matrix is 70% to 90%.

[0010] In this embodiment, a ZrC-based ultra-high temperature ceramic composite material is prepared by adding SiC whiskers and SiC nanoparticles to the ZrC matrix. Due to the good chemical stability of SiC, it matches the thermal expansion coefficient of the ZrC ceramic matrix. After hot pressing and sintering, the SiC nanoparticles Compared with the whiskers, it can be more evenly distributed in the matrix. During sintering, when the matrix grains grow up and meet the SiC nanoparticles, the interface energ...

specific Embodiment approach 2

[0011] Specific embodiment two: this embodiment is different from specific embodiment one in that the volume percentage of SiC nanoparticles is 8%-12%, the volume percentage of SiC whiskers is 8%-12%, and the volume of the ZrC matrix The percentage content is 76% to 84%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: This embodiment is different from specific embodiment one in that the volume percentage of SiC nanoparticles is 10%, the volume percentage of SiC whiskers is 10%, and the volume percentage of ZrC matrix is 80%. . Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com