Warm-mixed type water damage resisting asphalt pavement reinforcing agent and preparation method thereof

A kind of asphalt pavement, anti-water damage technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of scarce additives, improve coating ability, improve high temperature stability and high temperature anti-rutting performance, and improve water resistance Effects that impair performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

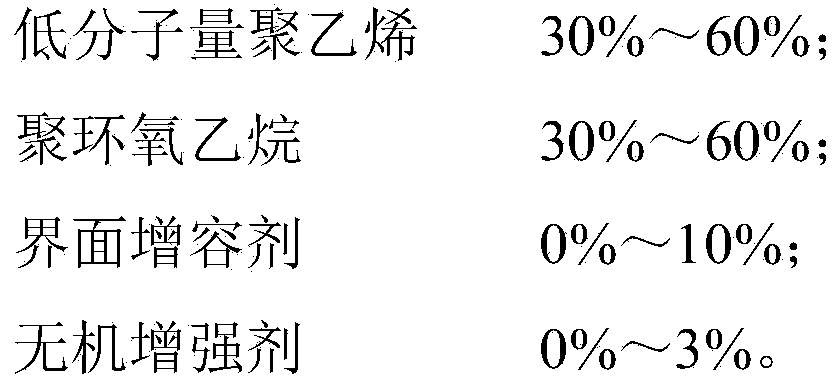

[0025] The warm-mix anti-water damage asphalt pavement intensifier of the present invention is composed of the following components by mass:

[0026]

[0027] Among them, the weight average molecular weight of low molecular weight polyethylene is 2500, the melting point is 99°C, the melting point of polyethylene oxide is 131°C, the interfacial compatibilizer is ethylene-vinyl acetate, and the content of vinyl acetate is 18%. The enhancer is nano calcium carbonate.

[0028] The preparation steps are as follows:

[0029] The above raw materials are mixed uniformly in proportions at room temperature, put into a twin-screw extruder, the blending temperature is controlled at 130°C, the screw speed is 85 rpm, the mixture is extruded by the extruder and then cooled to room temperature, ground and crushed to obtain the present invention Warm-mix anti-water damage asphalt pavement enhancer.

Embodiment 2

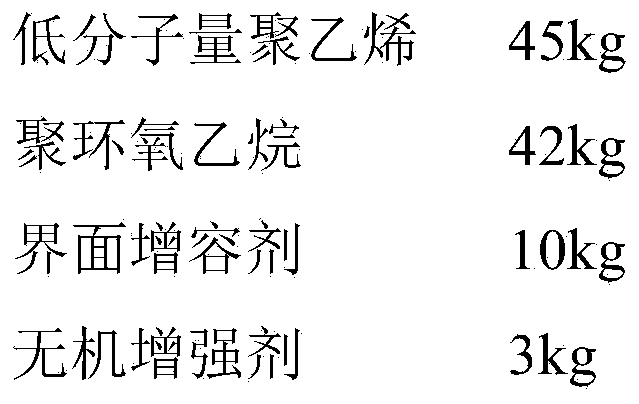

[0031] The warm-mix anti-water damage asphalt pavement intensifier of the present invention is composed of the following components by mass:

[0032]

[0033] Among them, the weight average molecular weight of low molecular weight polyethylene is 3000, the melting point is 85.6-106.5°C, the melting point of polyethylene oxide is 113°C, and the interfacial compatibilizer is a mixture of hard asphalt particles and ethylene-vinyl acetate. The mass ratio of hard asphalt particles and ethylene-vinyl acetate is 3:2, and the inorganic reinforcing agent is a mixture of nano-calcium carbonate and inorganic clay in a mass ratio of 1:1.

[0034] The preparation steps are as follows:

[0035] The above raw materials are mixed uniformly in proportions at room temperature, put into a twin-screw extruder, the blending temperature is controlled at 155°C, the screw speed is 90 rpm, the mixture is extruded by the extruder and then cooled to room temperature, ground and crushed to obtain the present in...

Embodiment 3

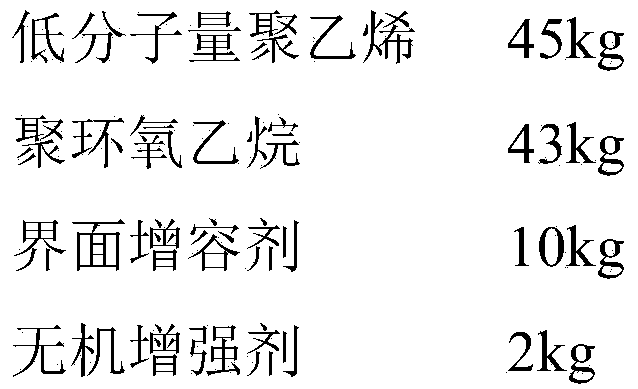

[0037] The warm-mix anti-water damage asphalt pavement intensifier of the present invention is composed of the following components by mass:

[0038]

[0039]

[0040] The weight average molecular weight of low molecular weight polyethylene is 2500, the melting point is 100°C, the melting point of polyethylene oxide is 131°C, the interfacial compatibilizer is hard pitch particles, and the inorganic reinforcing agent is nano calcium carbonate.

[0041] The preparation steps are as follows:

[0042] The above raw materials are mixed uniformly in proportions at room temperature, put into a twin-screw extruder, the blending temperature is controlled to 145°C, the screw speed is 100 rpm, the mixture is extruded by the extruder and then cooled to room temperature, ground and crushed to obtain the present invention Warm-mix anti-water damage asphalt pavement enhancer.

[0043] Verification example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com